Big Thanks to LB

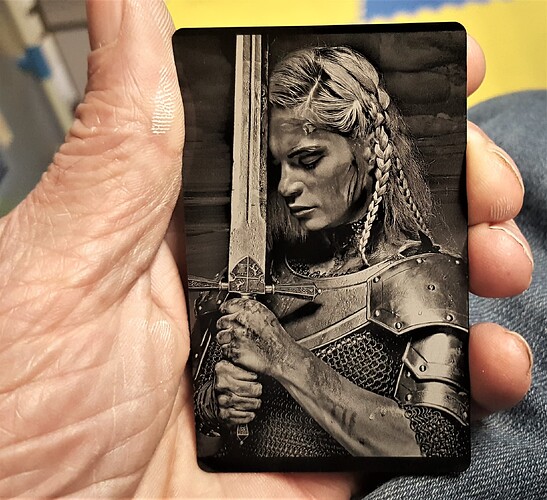

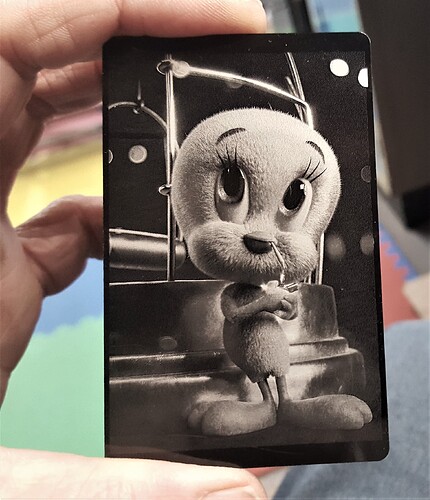

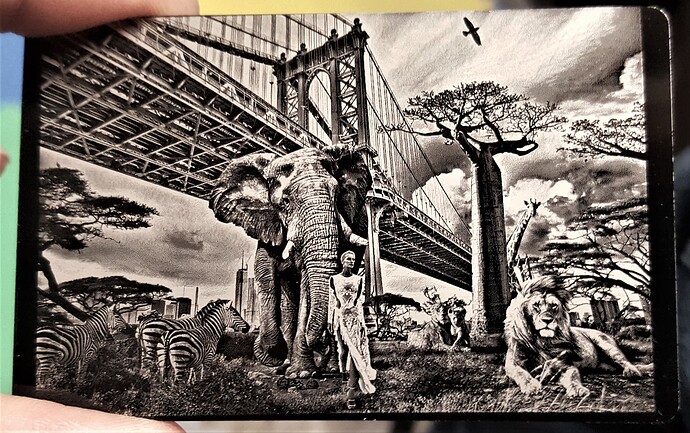

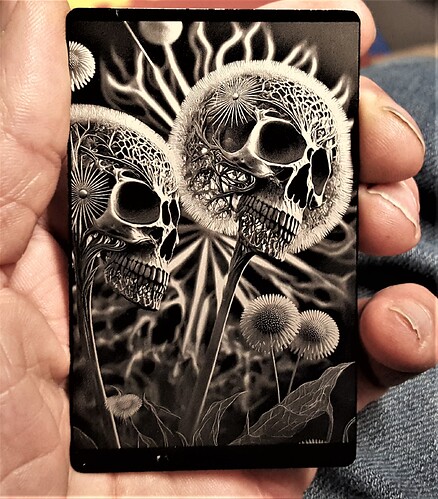

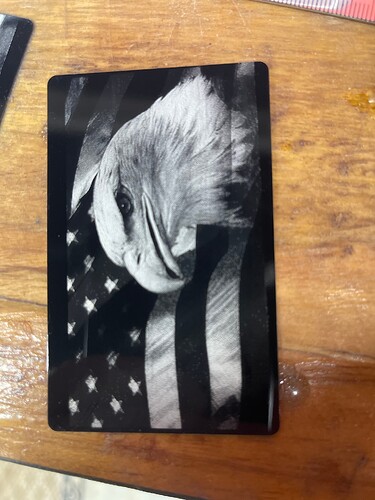

Playing with new JPT-H7 MOPA Fiber

Black Business Cards

Addictive

Thank you OZ

All done in LightBurn

These are great… mine always look burnt…

![]()

Amazing ![]()

Nice! Can you share your settings with us to get that kind of quality?

Those came out amazing! Great work!

Another great example of your stellar work, Nicky! Beautifully executed. What is this new fiber you speak of? Not seeing in your profile as yet, so must be a recent addition. ![]()

Settings

1100 mm/sec

25% power

400 Khz

200 ns

423 DPI

Inverted

stucki dither

@Rick Yes

Thank you

Just got it few weeks ago

OMG JPT 60 watt MOPA

@smg

1100 mm/sec

25% power

400 khz

200 ns

423DPI

Lightburn stucki inverted

I hate you. Now I have to buy a Fiber Laser. ![]()

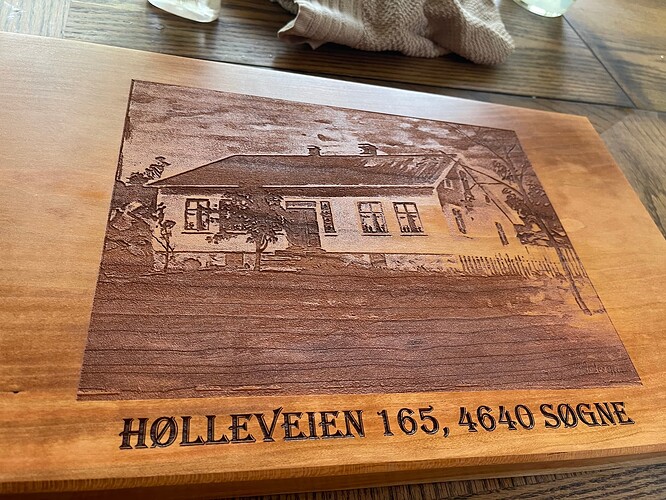

Those are amazing. Can’t get anywhere close to that on wood. Here’s an example over the weekend, maybe I need to work on my settings. ![]()

Which lens are you using?

I’ve found I have more adjusting for different lenses with the fiber compared to the co2.

I have a couple of tiles painted up with the acrylic/TiO2/water mixture…

There is a video by Laser Everything on photo engraving.

It is a great video that will show you how to set and get the best dpi possible for any laser with any material. It is well laid out with good graphics on what exactly is happening. It also covers the use of dot width correction, explained by the Lightburn developer… Simple touch of magic, you will want to use it…

I assume you do a lot of woodworking ![]() Hope you know a fiber doesn’t really work on natural materials, like wood… it also goes through glass and acrylic with no effect. These materials are pretty much not usable with a fiber.

Hope you know a fiber doesn’t really work on natural materials, like wood… it also goes through glass and acrylic with no effect. These materials are pretty much not usable with a fiber.

Fiber lasers are generally pulse lasers compared to co2 and most led that are continuous wave (CW). The frequency of a fiber is 10X that of a co2, even though both are in the IR spectrum.

Not woodworking, but this is a trick setup for a fiber laser making flexible and Kirigami circuit boards…

![]()

Yup, fully understand fiber is for metal. I have requests to do some guns. ![]()

I’ll have a look at the video. So far, I’ve just played with settings. Some come out good, others, not as detailed like the cutting board above.

Let us know how they come out in the “other” thread.

I use for now a 150 mm lens

Appreciate it. I spent $8K on a new laser and it’s going to be here Thursday… now my wife is angry again…she wants me to go back to buying guns. ![]()

All joking aside, looking forward to it. Already have some orders for stainless tags for offshore equipment. Still think those pictures are astounding.

How long does it take you to do those?

approx. 70 seconds

I can’t wait to get my new machine. ![]() Do you offer training classes for pictures?

Do you offer training classes for pictures? ![]()

Dude, your settings are spot on. THANK YOU. Got the laser yesterday… first projects. ![]()

The business cards take 10 seconds for the front.

Have you tried stainless tags yet? I’m lasering on Nitronic 50 and it’s lasering but it’s not getting black. I have some 316 tags coming so we’ll see, maybe Nitronic is too hard to turn black with not enough carbon content. . .

On metals, if you can’t feel the engraving, it’s annealing the metal… This is also what produces the colors…

I have some knives that are good and black, but at the right light angle they are almost imperceptible, visually…

Both images are annealed… The left image is from a low cost bag of dog tags from Amazon and on the right, a chunk of scrap steel, from a metal supply house (free)… Not much of a change with Felix to get a blue anneal… You can see the range with stainless on the dog tag… If you heat these back up to temperature, the annealed area will disappear.

Have fun, you’ve got a great machine… they are really incredible…

![]()