Me and many others have tried variations of the TiO2 power with different mixtures. I moved away from paint because of the toxic nature of solvents…

I initially tried Ethanol and Isopropyl alcohols. I live in a warm and dry climate (Arizona), so it dried up way to fast to be useful. It also didn’t dissolve… it would end up separated from the alcohols and sitting on the bottom of the bottle.

I have an air brush that I haven’t been able to unplug it…

Thanks for posting your work… we always enjoy seeing other people accomplishments.

Might check out this method…

Here’s a couple, done with a fiber…

This is done on aluminum card size stock and it’s got some kind of black coating, like this from Amazon…

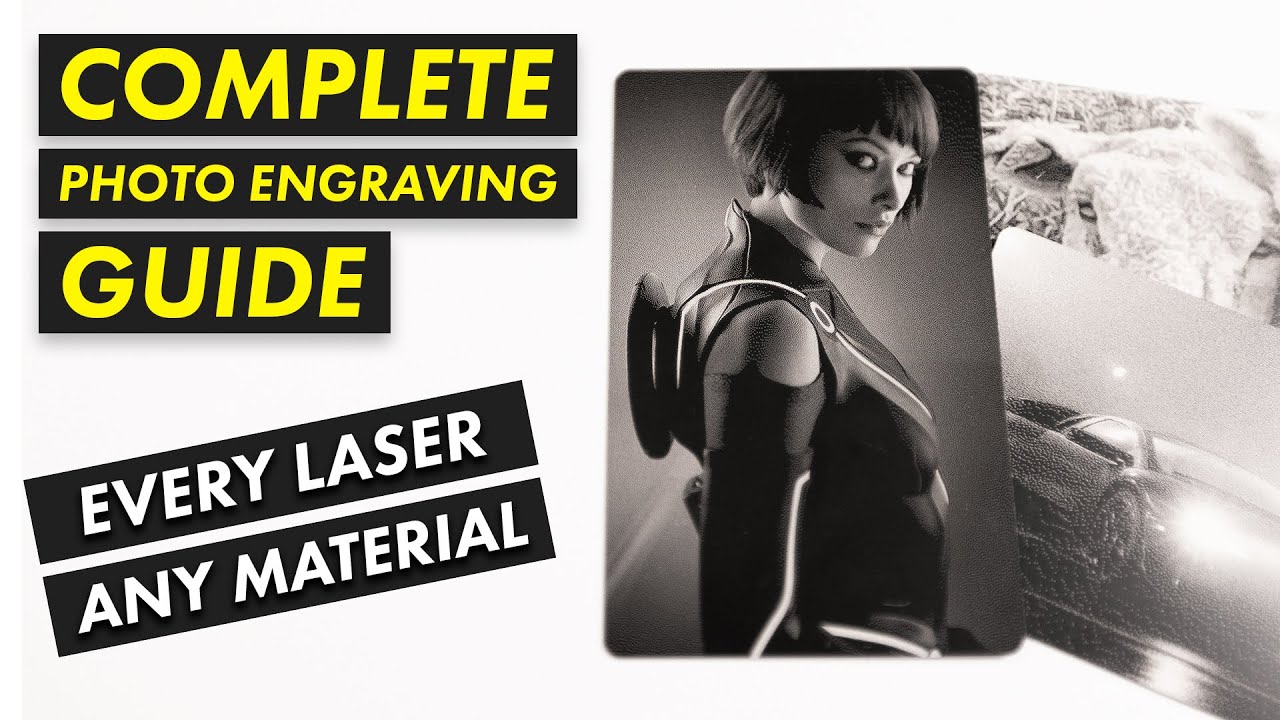

I think you could get better resolution, but I don’t know your setup. There is a laser everything video that has great graphics and shows you how to get the best dpi/lpi for any laser with any material… It has a bonus of one of the Lightburn developers explaining how to use the dot width adjustment.

If you haven’t watched it, it’s very beneficial.

Good luck

![]()