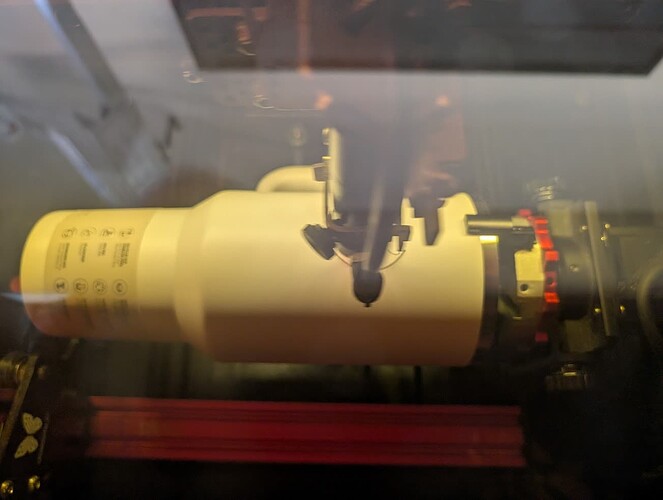

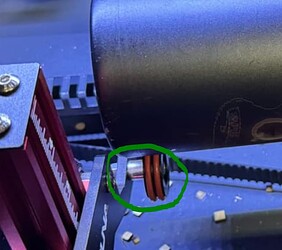

Been following this thread and it looks like you’ve done most thing correctly. I’m assuming you’re using the X axes to do most of the work and the Y axes only move at your interval… In simple terms you’re scanning the length of the mug/cup, not spinning it back and forth. The only other thing that can cause this to my knowledge is something is loose.

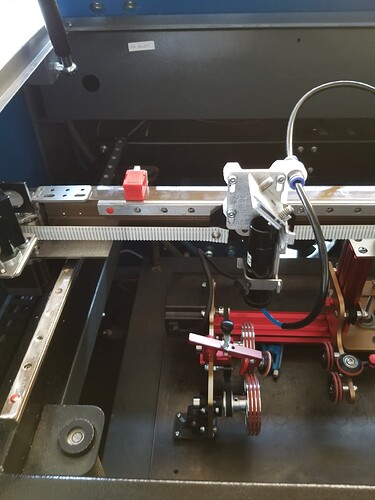

I have a PiBurn 3.0, no chuck, just rubber rollers driving the mug. In my case many of the Y operations were slowed down including the jump-off speed, which I don’t think you mentioned. It’s usually better to specify the actual variable you changed, not a translated equivalent. Such as line shift speed, which isn’t a specified setting, although I assume you mean acceleration of the Y axes? Jump-off speed is how fast it will initially operate, so mine is very low also. I have a machine settings file for using the rotary where all of these values are set, then reloaded when I take the rotary off the machine.

I hope you saved the original Ruida configuration, so you can easily go back to it. Might want to save the modified one also…

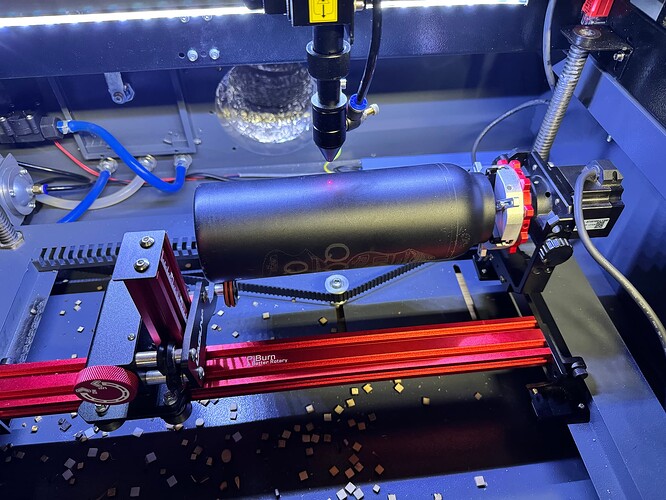

This is mine, it’s motor is to the left, hard to see as it’s black. When I first got it the image was mirrored, since I was more in a hurry, I swapped the direction of the rotary until I got around to re-wiring it for the correct phase inputs.

Since you are using a chuck model, most of these settings really don’t apply assuming the chuck isn’t loosing traction. The main reasoning behind the slower speeds is usually so the item doesn’t slip when you attempt to move it… with a chuck that’s highly unlikely. That mug probably less mass than your Y gantry with it’s drag chain plus the head and drag chain on the X axes… So your default setting should work. I doubt changing these is going to make much of a difference.

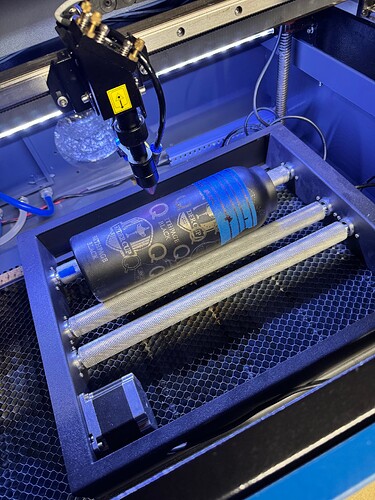

I have both a chuck (with the fiber) and a wheeled rotary (PiBurn) I got for the co2. I use them interchangeably with either machine… I’ve use the chuck on the OMTech co2 machine and the PiBurn on the fiber… same game. Steps/rotation changes as does mode, but they both work properly on either machine.

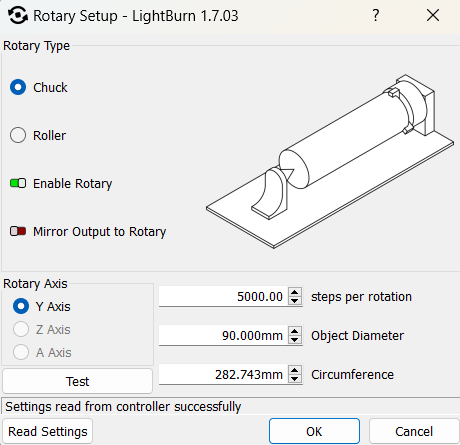

I also assume when you use the test button in the gui setup, that it rotates one complete rotation and back…? Even if your steps/rotation are off, it would result in a stretched or compressed image on the mug, so I think you’re setup properly. My PiBurn has a belt to the driving roller, which is a 2.5 ratio. I can’t see yours well enough but it appears as the motor drives the chuck directly, meaning, in my case it would be 2000 steps/rotation. However I’d expect some serious distortion in the image if you were off that much, so I’m assuming you’re values are correct.

@JimNM there is no overscan adjustment with a dsp unit, such as a Ruida, this is handled by the hardware based on acceleration values.

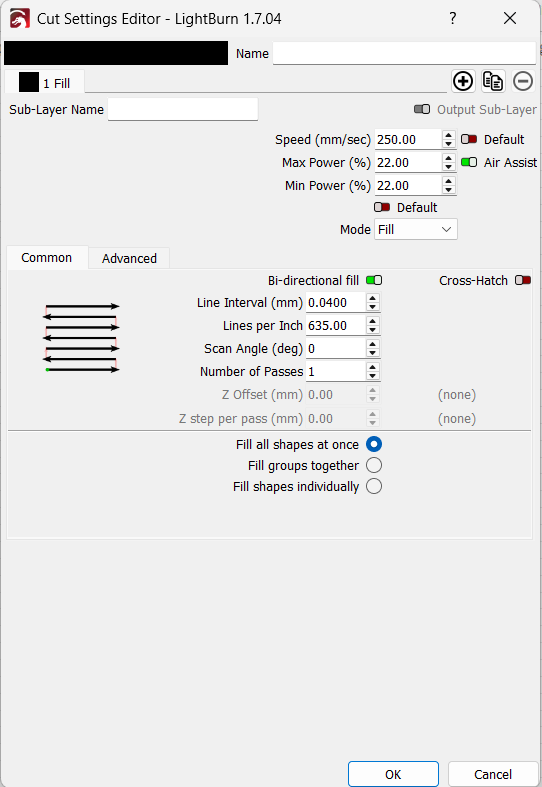

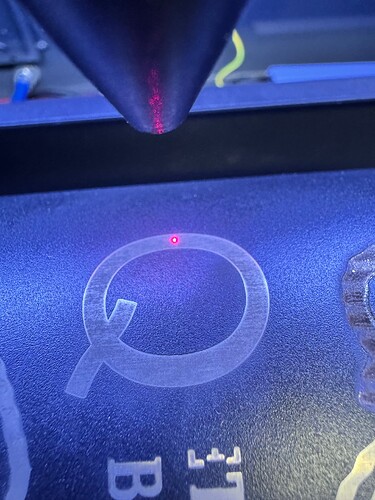

Sorry to hear you’re having issues, most of my experience has been very good with PiBurn, but again, I’d ask the factory for help in a resolution to this… I hate to say, I don’t see anything that would cause this. You interval is rather small as most co2 have at least a 0.20mm spot size, that’s something you have to figure out with the type of mug and coating.

I’d suggest you contact PiBurn with a link to this thread, if anyone has a good idea about it, it’s likely the manufacturer.

Sorry for little to no help here, that’s why I suggest a note to the manufacturer.

Good luck – we’re waiting for the fix to be revealed to us, so will be waiting on your replay