Is there not a strainer or perforated plate before the extraction hole, on the inside of the laser machine, to catch sailboats, prams and similar large items?

No, some chinese models have an actual dust collection plate and the fume extractor fan draws in from there. My model has a motorized Z axis so it doesn’t. The fan is on the left side, bottom about 2" off the floor.

I currently use the top left window that’s used for mirror adjustment (I can still use it, the filter is removeable) and the normal extraction area. Larger bits hit the bottom, the filter already has tiny bits, honestly very small, .0125 mm or less that float over and fall to the inside of the case I built.

To be honest translating this is funny, but I understand the euphemisms.

It’s just a few particles overall to be honest. But my pre filters were coated in fine dust and resin. I couldn’t get light through them. Blowing them out didn’t work either. I will opt for a larger washable pre filter on the next design.

I would think that the resin/wood particles would fall down as they should be heavier in one of those catchers as they are resin coated dust, but apparently not.

We use it as a “classification” for very large or bad filters and it is of course humorously meant ![]()

I get it. I love international humor even if it’s common.

Correction regarding fan. Looks like average 200CFM for stock fan. I don’t remember where I read 45. It might have been when I was designing my air assist.

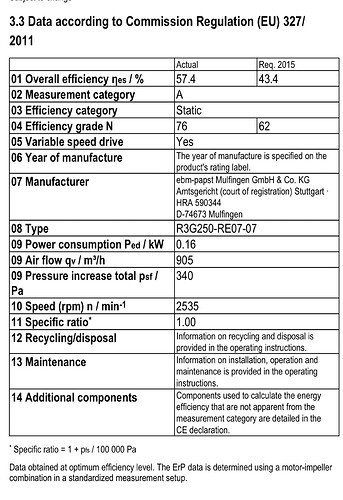

So, I’m extremely stubborn and ordered the 1100m3/h pipe fan I mentioned earlier: "Prima Klima"

Of course I’ll report back what the results are.

The most interesting part of this fan is that it has an RJ45 connector for an external speed regulator. I’ve mailed the manufacturer about the technical specs of this connector. And totally against my expectations they mailed me back. Within 10 minutes. On a Saturday!  And best of all: they mailed me the full technical schematics and drawings. Allowing me to build my own PWM controller.

And best of all: they mailed me the full technical schematics and drawings. Allowing me to build my own PWM controller.

My aim is to build a controller that is activated by the laser (Run signal) with a predefined period of running after the the laser job is done. The connector even returns an RPM signal, so I’ll probably end up building a custom PCB with oled screen allowing me to configure the laser controlled fan and reading out the RPM. That’s a nice weekend project!

Anyway, as soon as I have more news about this project or if the 1100 m3/h is sufficient for my machine.

Do they give details about static pressure etc?

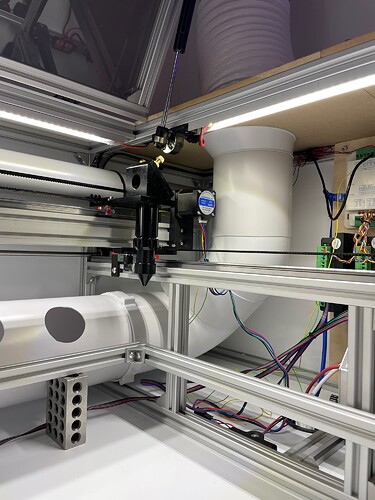

Received my fume extractor fan today. Can’t try it in my machine yet but it seems to have some serious power while being pretty quiet.

As soon as I have results I’ll post some details.

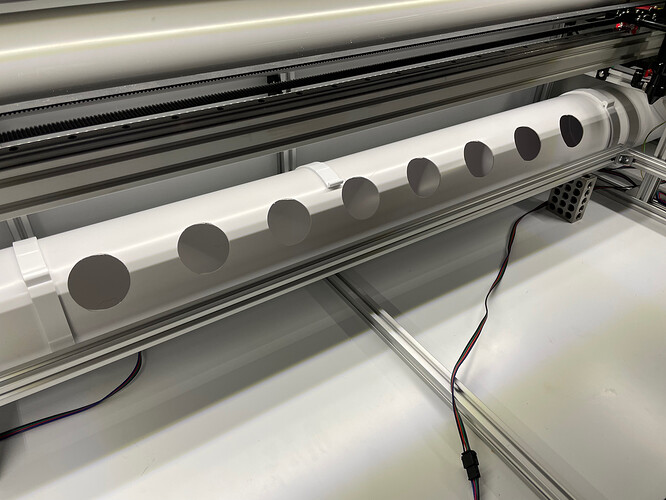

Still need to incorporate the air intakes in the front of my machine, but the exhaust is connected and seems to be working.

Cutting will most of the time be done on near the right side. So it’s correct that the airflow is larger here. I might even create some “plugs” that allow me to (partly) close gaps.

But it’s a good observation!

I ran the ducting through the walls and out of a basement closet. There is a metal “pan” in the wall to which the flanges are mounted. See: https://bronkalla.com/blog/2021/11/07/laser-exhaust/

For plugs try simply slitting some pipe lengthwise leaving 60% to “Clip over” the holes like a sleeve. (i think the 1,2,3 blocks are amusingly excessive haha).

Haha. Those blocks were temporary. I hadn’t finished all the z-axis drive rods yet.

Most of ya’ll have some HUGELY impressive machines, as well as ‘extraction setups’.

My first question to all, is have ANY of you experienced any kind of fire, smouldering, sparks, and the like? Secondly, have any of you noticed any buildup of soot or creosote inside your ducting?

I’m looking at setting up a ‘laser room’ for My Lady and her business venture. As she is susceptible to ‘scent induced headaches’ I have focused simply on ‘containment’ around her laser (xToos D1) and extraction through directly plumbed bathroom ceiling fan and ducting.

Growing up in a household where my father was a fireman, I simply want to exclude the possibility/potential of the typical ‘chimney fire’ and such. At the same time, I’m completely aware that I may be ‘overthinking’ this. Question is, am I paranoid enough, or too much?

We’re definitely new at this Lasering thing, but ‘burning wood’ is still burning wood. No matter the ignition source. Hence the curiosity. Thanks for ready, and I look forward to further replies on this topic.

Yes, It goes with the territory

Just stop right here and create a powerful HEPA setup.

You want a good size area for prefilter to catch bigger particles and then keep getting finer and finer filters until you hit MERV 15 or 16, you’ll be able to vent in the room or outside with no soot or smoke buildup. Vent it outside though.

You need a fan with around 400CFM and good static pressure. The more the better. As the filter clogs the fan will draw less, so you need pressure or sucking ability to remove it and filter it.

Don’t run the laser unless inside unless it’s fully enclosed.

So, with it ‘going with the territory’, what are the experiences with sparks/embers/flames reaching the filters, and turning a ‘small flame’ into a ‘towering inferno’?

(old 70’s movie pun injected there, to show age and humor)

My main focus for us here, is ‘extract bad air to the outside’ while bringing in good air to breathe. Up here in the North, it is -25/-37 right now (high for the day) and will only get colder through the afternoon to -31/-43 tonight.

Point being, we’re not looking at something that does 500 cubic feet per minute (CFM) or anything like that. Doing such would ‘supercool’ the house.

That’s what I’m experiencing right now. If I run full power with my extraction / filter, my small workshop in the basement will be quite cold. People often forget that the same amount of air that is sucked out - must enter the house again. At about. 0 degrees Celsius, it costs something extra to compensate for this heat loss. Another important thing is to close the vent hole when not working, no matter if the fan is running or not, the pipe system acts as an exhaust system and sucks air out of the housing. (it works like a chimney)

there is ducting which is double walled which is often used for closed system wood burning stoves. Something like that might help you guys but you would have to build your own way to duct the intake into your laser box.

would have to watch out how cold the air is entering the laser or it might cause condensation on the mirrors and effect power levels.

Yes DougL, as well as ‘super-cooling’ not only your laser but your workpiece as well.

Heat exchangers of one manner or another, are a HUGE consideration in our houses here in the Northern climates. Hence why for some of us, there is ‘so much more’ to consider than ‘plug it in and turn it on’. Add some health problems to that, fire hazards, and a few allergies too, and this ‘unique endeavour’ turns into a “gargantuan project of many tangents”.

Breathing air

Fire prevention

Temperature control

Air exchange

Air Filtering

Heat exchange

Stable workplace (wife’s kitchen table doesn’t work, even for HER laser)

So instead of doing things multiple times, I/we are just trying to cross all the ‘i’s’ and dot all the ‘t’s’ all at the same time. Once.

Thank you.