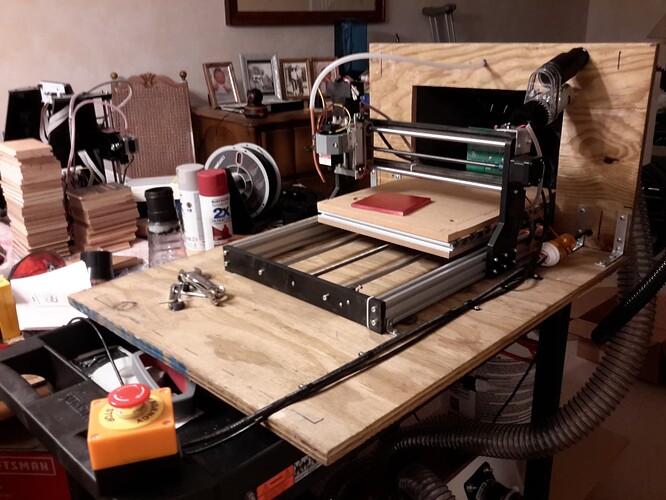

Here is my final version of my CNC/Laser workstation. The project spread out over about 2 years. This invention was a necessity because the Florida heat is a mother. Working in the garage was not an option. After a lot of trials, I finally settled on something I can use in the house, and roll out of the way when done playing. This setup permits rapid switching between CNC and Laser operation. CNC use is stand-alone, and for the laser, I only need to find a suitable window. Below each picture will be a description.

The base machine is a Sainsmart 3018 Pro with the 3040 table extension. This gives me just under 300mm squared working area. The back panel has the 12" sq air funnel for laser work. The upper right on the back panel has the vacuum hose (milling motor and brush attached for show, normally stowed). The cluster on the front left is magnets to hold the tools needed for both CNC and laser work. The yellow blob is the E-Stop switch which kills all power to the controller board. If I hit that button, I want everything to stop, like right now.

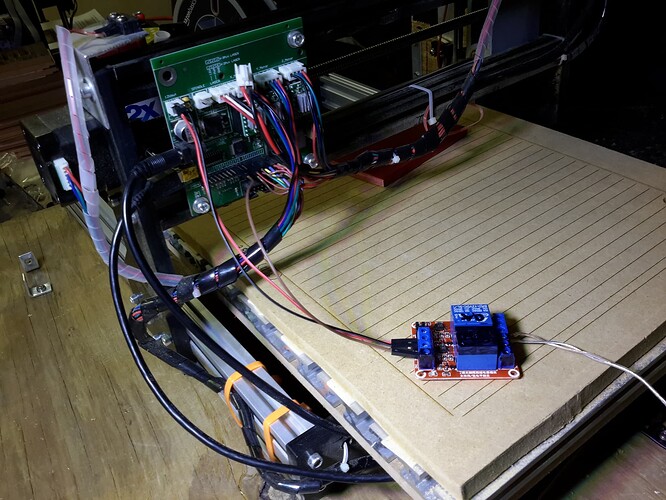

Below is the Board for the window exhaust fan when using the laser. Behind it is the Shop Vac used tor pulling dust from the CNC milling. All wheels swivel on the cart, so it can navigate through some pretty tight areas.

Here you can see the vortex dust collector sitting on a 5 gallon (paint, pickle, etc.) bucket. I was surprised on how fine a dust that thing can catch. Above it is the back of the funnel and the 3" variable speed duct fan mounted on it. Top left of the backing plate is the air assist pump and the right (not visible) is the power strip for all the devices, with a 20’ orange extension cord to reach any nearby outlet.

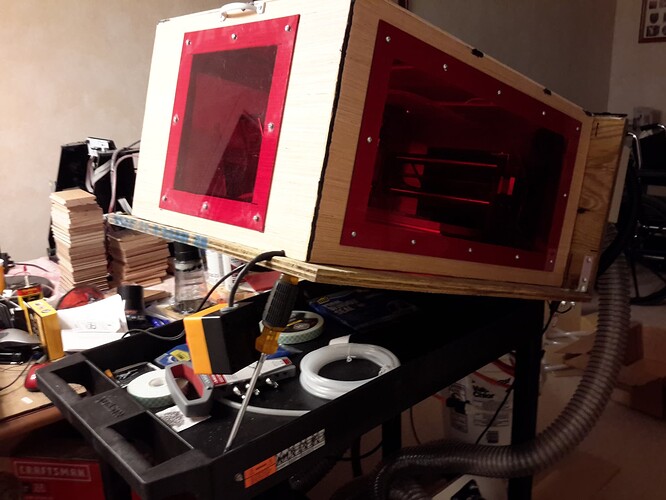

Here we see the box with observation windows, laser safe of course. The front and top have handles to easily lift it off for easy access. And finally, the cart is a tray cart, so I created access to the storage space under the machine. If you lift it high enough, a copper rod drops down to hold it up.