Newbee question here, I have the Creality 10W diode laser on my 3D printer. Not the most ideal solution but a great and affordable way to start engraving with this laser. I am making front panels (faceplates) for flight simulation hardware. We cut out the holes for the electronics, buttons, displays, encoders etc. We do that with a CNC machine out of white casted acrylic, 5 mm thick. Next, I apply a coat of primer and 2-3 coats of dark grey paint. I use the laser to engrave the text and symbols. I need to position the text and symbols at the exact right position on the faceplate. What is the best way to do this?

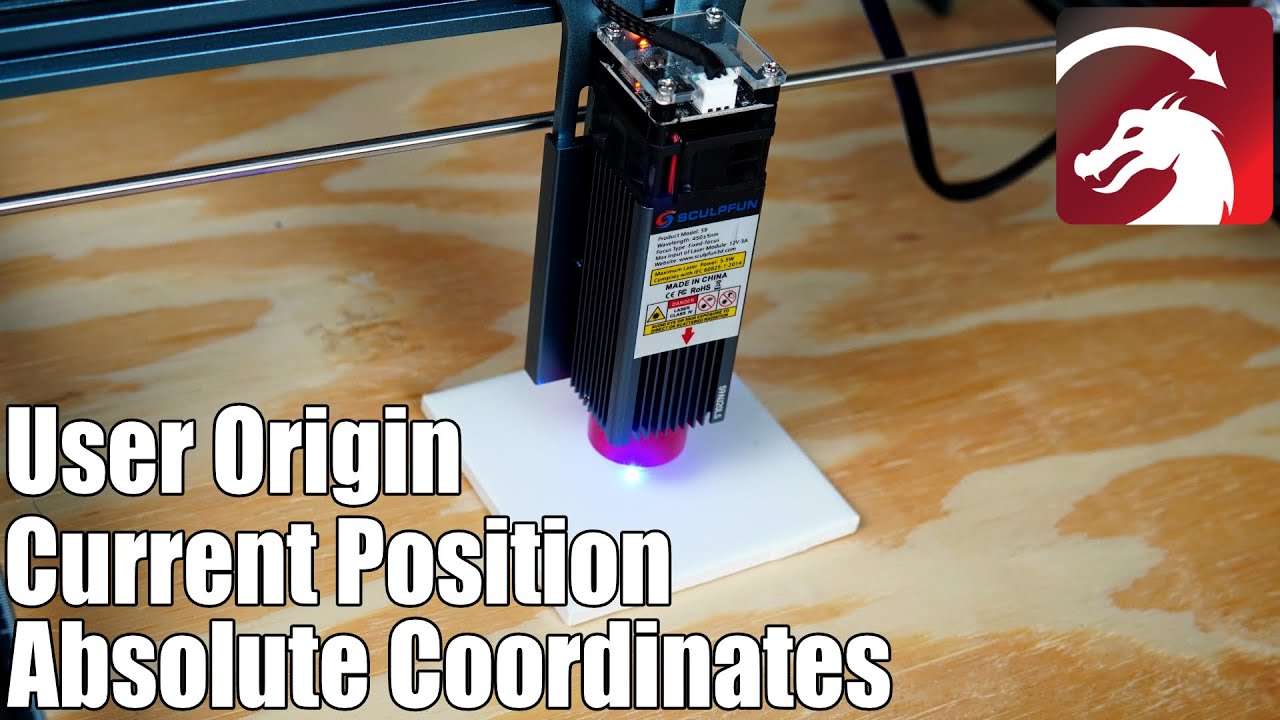

The best option may be to use ‘Current Position’ as your ‘Start From’ mode. Here are a couple of resources to help you get familiar with the way this setting works:

If you mean the location of those elements within the panel:

- Export the CNC design as a DXF

- Import it into LightBurn

- Put it on a tool layer

- Delete anything you don’t need

Now you have a layout guide exactly matching the drilled front panel: arrange the graphic elements around the holes.

Physically aligning the panel to the laser calls for a fixture. Use the perimeter of the imported DXF to cut a hole in something like MDF, mount that in the laser, and drop the panel into the template for engraving.

You could add a pair of targets to the LightBurn template layout (outside the hole for the panel), burn them on the MDF, then use Print-and-Cut to align your graphics to the template:

Thanks! I will give that a try!

Thanks for the info, I will try all options to get a better understanding!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.