This is very interesting. I haven’t used XCS so I will need your assistance to confirm some settings.

Small Y-Axis travel errors can be created by Lost Motion. Lost motion is like a car spinning its tires. The motion is counted by the instrumentation but the actual travel distance is lost.

There are a couple of ideas leading me in this direction.

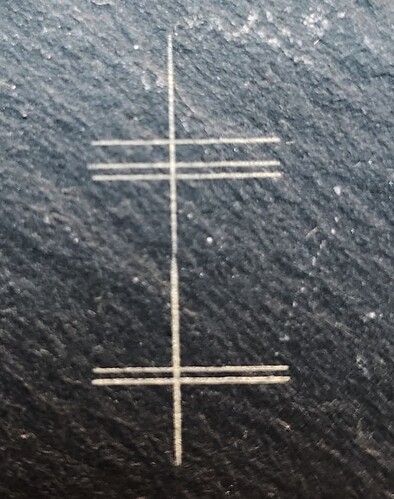

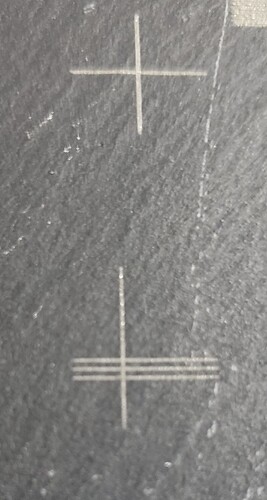

- The variation is a few mm and it is in the Y-direction only.

The engraver moves more parts (more mass and weight) when it moves in the Y-direction because the whole gantry has to move. Moving in the X-direction can be successful with higher accelerations because there’s less mass to move. Force = mass * acceleration

F = m * a Force is what causes the toothed belt to move or skip.

- The GRBL controller counts every step.

The error isn’t reproduced perfectly / identically each time. The variation is outside the counted part. This leads us solidly to a mechanical variation.

An acceleration setting that’s very slightly over what would be perfectly repeatable is the idea I’m leaning toward.

I’d like to explore the speed and acceleration settings in LightBurn and XCS to confirm that they’re identical.

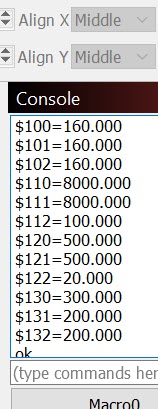

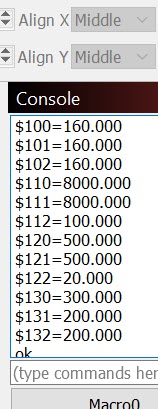

In the Console window in LightBurn please type the following:

$$

then press Enter.

Please select and copy the text in that report from $100 until the end of that report and paste it into a reply here.

Because we only need a few numbers, a screen capture isn’t too bad.

Your numbers will be different than mine. That’s fine.

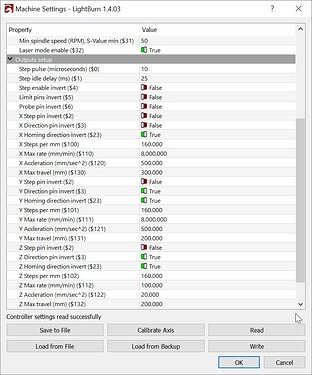

These numbers are also in Machine Settings. To access them click Edit, then Machine Settings then click the > symbol in the last line next to Outputs setup. Skip the dire warning.

Click to expand Image

Note here that the Units are shown. Knowing the Units applied to acceleration (mm/sec^2) and speed (mm/min) is critical for comparing them.

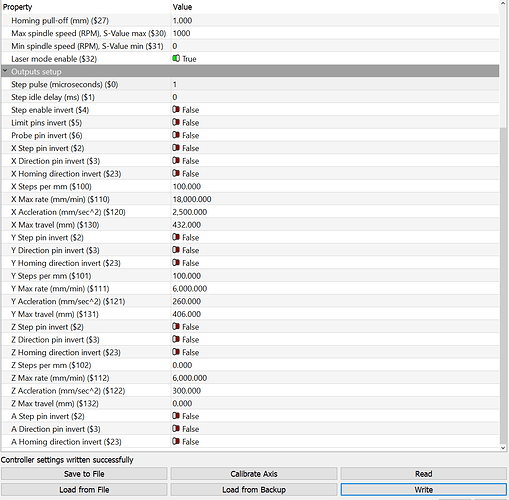

In XCS, find the machine settings that relate to speed and acceleration.

Please screen capture and share that Image here. You should be able to drag and drop it from your desktop into the reply window where you type your response.

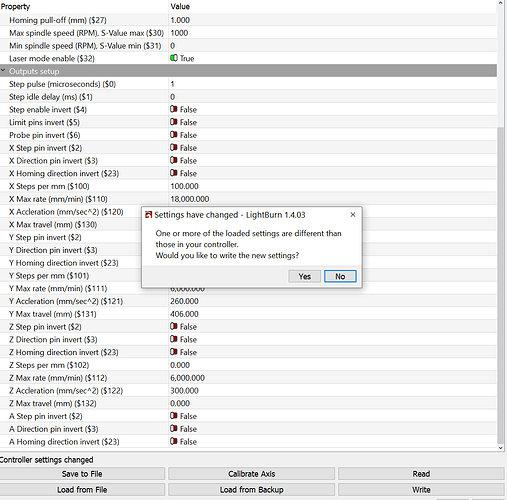

If the settings are different, you can adjust the settings in LightBurn to match.

If the settings are identical (speed, acceleration, and their units) we’ll test the Y acceleration settings to see if an increase makes the error larger and a decrease makes the error vanish.