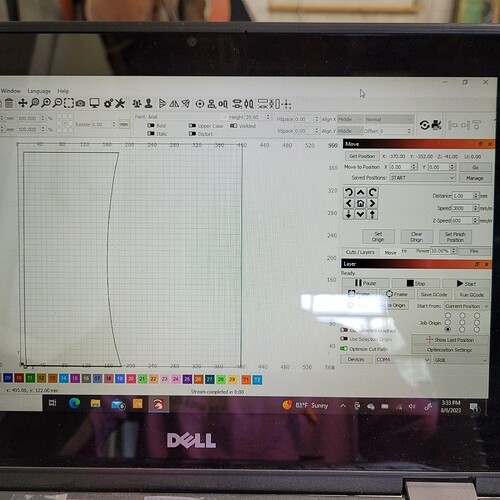

I need to cut this template. The preview shows no problems but the laser goes right, then up, then stops. Not as though it’s reached a limit switch, though. Is there something about closing the shape I’ve missed?

Also, I experimented today with maximum boundaries. I woul assume that my machine home to 0, 0, but i have to move it Y 45, X 40, to be at the corner of the cutting bed. That makes my project appear on the drawing board as a different position. If i adjust it, i get out of bounds message. It’s not because of the laser, the spindle was the same way. Most things i do don’t have close tolerances so i just hit and miss, but I’d like to get maximum length out of this cut. It has been very wonky and frustrating today.i did a maintenance to the best of my novice knowledge, screws are tight, belts are tensioned, gears and wheels are clean. I guess this is two separate but related problems. Making the template is priority.

Thanks.

I suspect you have an incorrectly configured work offset.

Read through this carefully and evaluate if this applies in your case.

Ok, I’ve read this, i actually had printed the pages and highlighted some stuff prior, but sometimes things start making more sense after you’ve been hands on for a while. I was following fairly comfortably until Lightburn said “…if it moves 10mm, etc,… you simply set the origin to match the origin discovered above.” Stop the bus! Set the origin where? Set it for the full 40 mm that the head is off the work area? Set both x and y?

You worked tirelessly for 3 days to get my machine functioning, i don’t want to jack it up somehow!

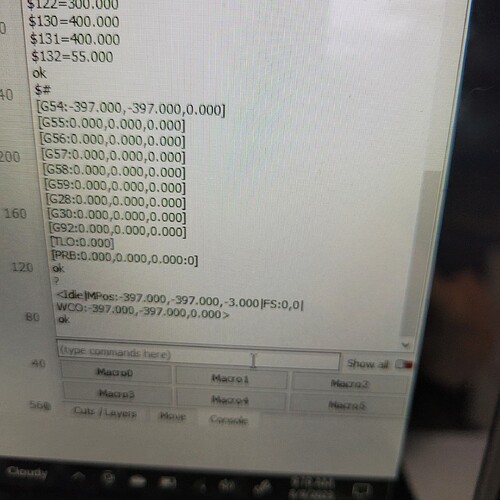

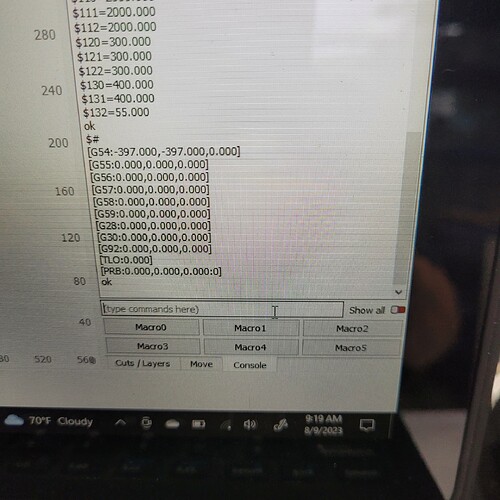

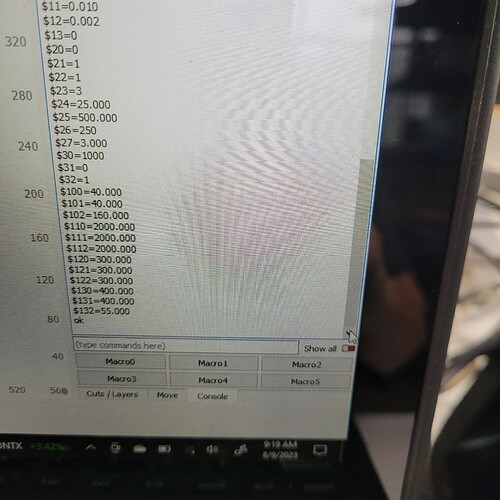

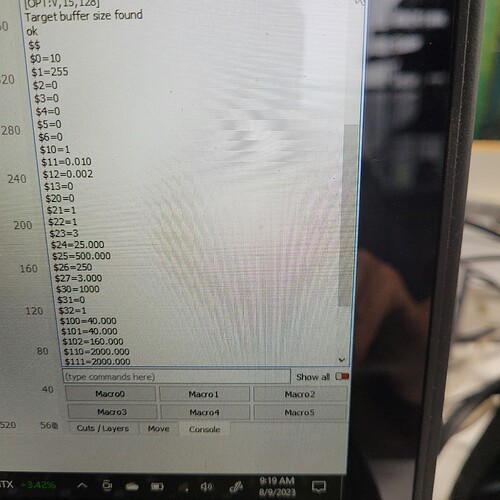

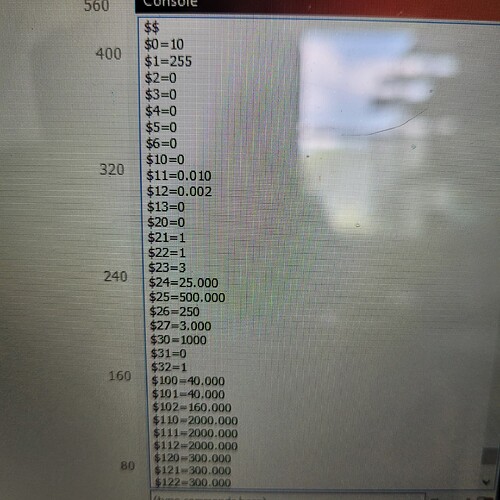

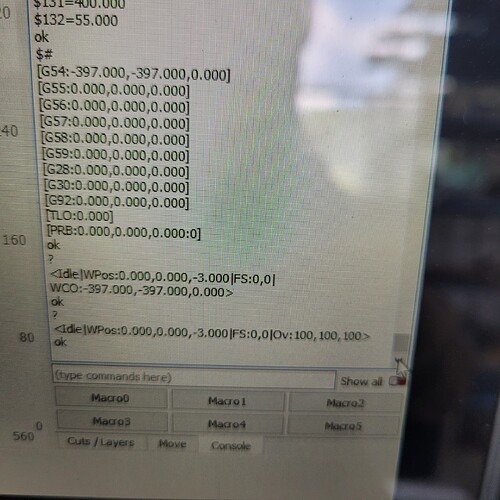

Can you run these commands one at a time in Console and return output?

$I

$$

$#

?

Also, please confirm the actual dimensions of your laser?

I’m not sure what you mean about actual dimensions of laser. The housing is 2 5/8 × 2 5/8, x 4 1/2, plus the 1 1/4 in amber shield. The laser head sits forward about a half inch from center. Toward the bottom.

Somewhat non related question…if $111 = 2000, is that the max speed laser will run, regardless of individual settings?

What is the working area of the bed? Is it 400x400 mm?

That’s the maximum speed the laser will run on the Y-axis. $110 is for X-axis.

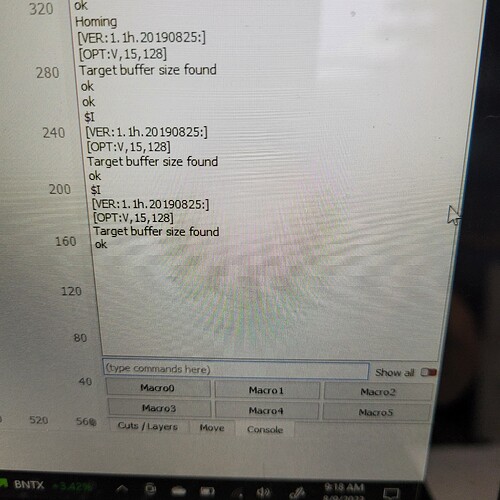

Can you run this in Console and then return the output? You can copy the text from the Console window as that will be easier.

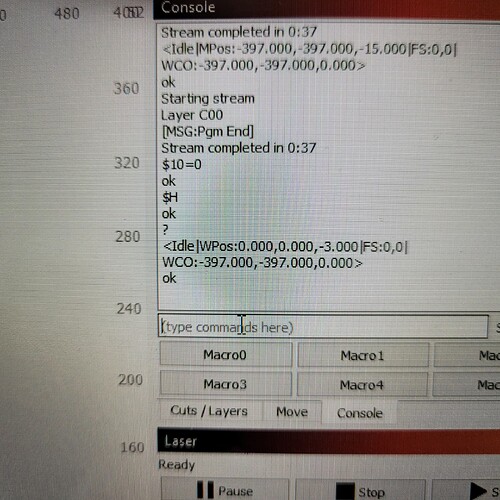

$10=0

$H

?

Note that the second command will home the laser so be prepared for it.

I’m sorry, I don’t think I can show from console without internet. Yes, dimensions are 400 x 400. No internet in shop.

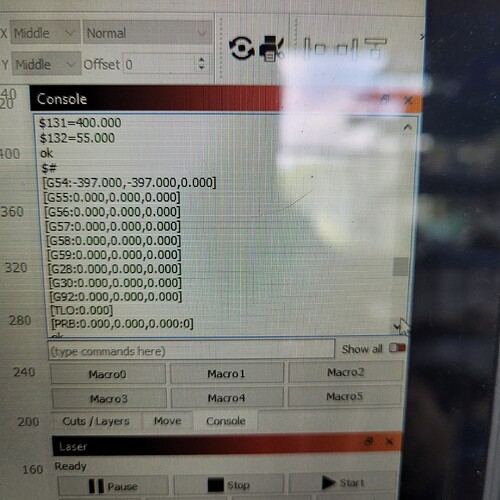

Okay. It looks like the change should have worked. Can you now test the laser?

Select “Absolute Coords” as the Start From mode in Laser window and attempt to frame something. The location on workspace should match the location on your bed.

Yes, it did. Once again, berainlb, you have worked patiently to help me solve a problem. I was starting from zero knowledge, I’m learning but it’s a steep curve. Thank you so much, you are greatly appreciated!

I have a serious love/hate relationship with this machine.

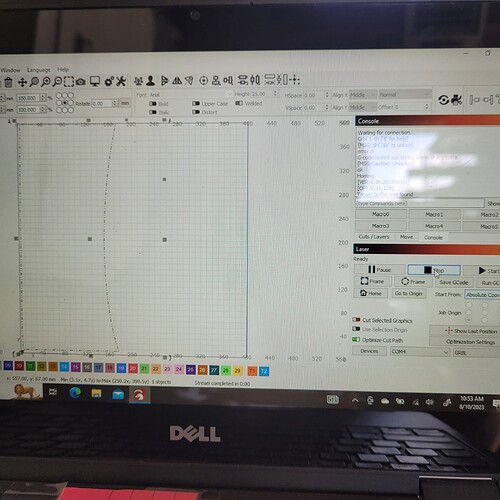

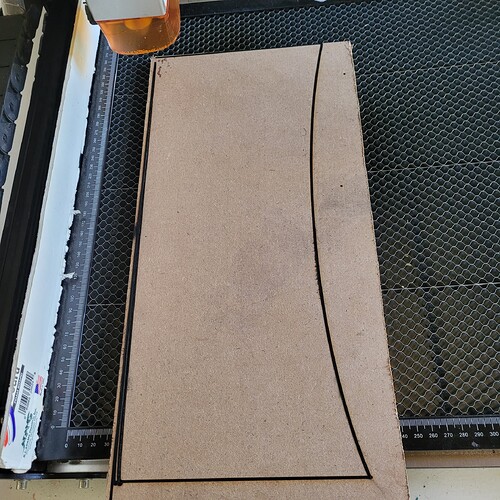

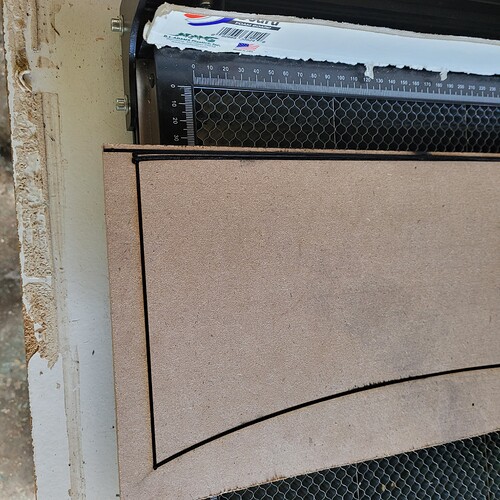

It refuses to run this simple cut. It is a closed single rectangle that i used the distort tool to create the curve. It runs fine in the preview, left side, bottom to top first. Frame sends it to the bottom right, then straight up, then stops. No limit switches triggered.

Are you using other programs than LightBurn to run the machine at times?

Can you run these commands in Console and return output?

$H

$$

$#

?

Again, sorry, no Internet in shop. LaserGRBL and Candle both installed but i don’t use them. Lightburn is a great program.

Don’t see an obvious issue there.

What happens with the laser after you attempt to frame this? Do you need to reconnect?

Can you take a screenshot of any Console output after attempting to run this?

It randomly ran one full pass, after moving to the left past the cutline, then back to the curved cut, then at the end it did two dots about where the distort nodes were. Now it will only run the left vertical line. And at 100% power, just scoring the mdf, nowhere close to cutting through. Also, it apparently didn’t 'remember ’ the fix we did yesterday, still off 40 mm x and y.

Can you confirm that you’re not moving the laser head by hand? Meaning that you’re exclusively using the jogging controls in Move window to move the laser?

Do you have any reason to believe that the laser should cut through the material with these settings? Have you run a material test to confirm?

From looking at the burn, it looks like the laser may not be in focus. The burn line looks very wide to me.

Yes, the burn line is wide! It is a fixed focus 80w foxalien laser. More learning on my part, i run the tests but don’t always know exactly what they’re telling me. As i said, sometimes things i read don’t always make sense until there is some hands on practice. From my understanding, fixed focus means it is supposed to be focused by using the piece provided to set it?

Keep at it. Things will become more intuitive as you familiarize yourself with each aspect of the process.

Yes. Make sure you’re referencing against the correct part of the laser module. Not sure where this is on your machine so suggest you check the documentation if you’re uncertain.

Yes, thanks for the encouragement! I know a lot more than when i started. This forum is a wonderful asset!