Hey out there.

Today I thought I would give Print and cut a go. I watched the tutorials several times to make sure I was doing it right. As far as I can tell I have. But it doesn’t work.

I sent the first and second points with no issues. I tell it to align with no scaling and that seems to work.

I can see it states Print and Cut on the message window.

But when I hit go. It moves to the registarion marks and then is done.

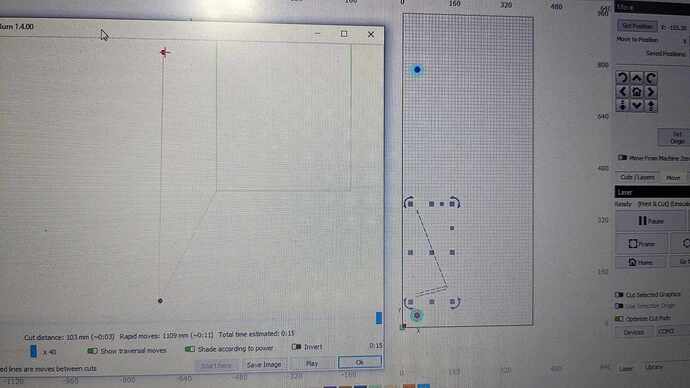

When I check the Preview there is no object to cut. Just a strange pale blue rectangle.

Sorry for the poor image but this computer is not networked so i can’t screen grab it I had to use my phone.

But on the left you can see the preview and on the right is the object I am trying to cut.

I have noticed that if I change the Co-ordinate system from Absolute to something else the image appears. Something is off.

Another observation.

If I input say x 5mm and y 5mm and press go it runs off to the far side of the machine and hits the rail. Clearly something is amiss.

Any help would be appreciated.

I have a theory. I suspect Lightburn assumes that the laser passthru is front to back versus from the side.

In my case it’s from the side and so the registration marks are down the side versus the top. This I think is what’s messing up the co-ordinates.

Will test me theory tomorrow.

I’d like to tag onto this. I’m brand new to lasers and admittedly not a computer guy. I’m having to same problem. I engrave / cut one side then flip my board. Use the registration marks but nothing happens. Yesterday I noticed nothing appears in the preview window. I know it’s me and software but if anyone could help.

I got mine to work today.

Seems the passthrough function is intended for front loading and not side.

So when I put both registration marks at the top of the image it worked.

I had them down one side because it was a side passthrough.

Are you referring to how larger material is passed-through the laser frame? If so, this may be a false positive. There should be no relation between the orientation of the registration marks and the functioning of print and cut.

Typically you want the marks to be placed as far apart as possible to reduce any potential locating error.

Having said that and reading your original post, not sure what might have been going on in your first attempt.

Hey there.

So when I tried it the first time I had the registration marks down one side and they where far apart.

IT didn’t work. However if I moved the registration marks to the top of the image it works fine.

With one exception. When the job was over it ran off into the rails and I had to power it down to prevent damage. I suspect that might be a user issue.

But the registration marks…no way would they work.

This plus the issue withe the vertical registration marks is indicative of a different root cause.

The crash should not occur if the controller was aware of position and reported it correctly to LightBurn. I assume this means one of the following:

- The machine does not home correctly. Is your machine equipped with homing switches or are you manually homing the laser before power-on?

- Are you ever moving the laser head by hand? Especially post homing? If so, you would cause the controller to lose position. Use jogging controls exclusively after homing.

- From the screenshot it looks like you’ve added the extension to the laser. Have you updated the controller with the increased dimensions?

- Is soft-limits enabled on the controller?

- Is “Enable out of bounds warning” enabled in Edit->Device Settings

If all the above are followed most typical crash scenarios should not occur.

Hey there

Thanks for getting back to me

- The machine does not home correctly. Is your machine equipped with homing switches or are you manually homing the laser before power-on?

The machine has switches and seems to home properly.

If goes to the front left corner if your facing the controller.

- Are you ever moving the laser head by hand? Especially post homing? If so, you would cause the controller to lose position. Use jogging controls exclusively after homing.

No I jogged to position. I have a small CNC router and 3d printer so I am familiar enough with the workings to ensure I jog to position. Now I admit I am not sure if I should then be setting the origin or not. In a CNC router I would then tell it this is the start location…so not sure if I should be doing that.

- From the screenshot it looks like you’ve added the extension to the laser. Have you updated the controller with the increased dimensions?

I have updated the dimensions in the machine config. I checked them to make sure I had it right. Now I admit that perhaps the values could be off slightly like 941 when it should be 940 and so on. But they are set.

- Is soft-limits enabled on the controller? Yes but I will double check. But I am pretty sure they are turned on.

- Is “Enable out of bounds warning” enabled in Edit->Device Settings

I will turn that on if it’s not on.

I have observed that if I home the machine and then tell it to go say to X5mm and Y5mm…it races across the workspace into the machine rails. As if it’s not honoring the workspace co-ordinate system.

Also if I home the machine and do a get position the values are in the negatives which I believe is correct.

Print and cut relies on use of Absolute Coords. It should be automatically switching to Absolute Coords once engaged, however.

This shouldn’t be an issue as long as you’re not at the very limits of travel.

This is likely the root cause of the problem.

LightBurn relies on use of positive coordinates. This seems odd, though, as extending the rail should not have changed origin.

Can you run these commands in Console and return the full output?

$H

$I

$$

$#

?

Note that the first command will home the machine so be prepared for it.

per the Origin question it was more of a regular day to day use question.

As for the commands I will run them as soon as i can. Company coming shortly so need to get cleaned up.

Thanks by the way for your assistance it’s greatly appreciated.

Here are teh results of those commands

Waiting for connection…

Grbl 1.1h [‘$’ for help]

[MSG:‘$H’|‘$X’ to unlock]

error:9

G-code locked out during alarm or jog state.

[MSG:Caution: Unlocked]

ok

Homing

[VER:1.1h.20190825:]

[OPT:V,15,128]

Target buffer size found

ok

ok

$H

ok

$I

[VER:1.1h.20190825:]

[OPT:V,15,128]

Target buffer size found

ok

$$

$0=10

$1=25

$2=0

$3=0

$4=0

$5=0

$6=0

$10=0

$11=0.010

$12=0.002

$13=0

$20=0

$21=0

$22=1

$23=3

$24=200.000

$25=3000.000

$26=250

$27=3.000

$30=1000

$31=0

$32=1

$100=80.000

$101=80.000

$102=250.000

$110=6000.000

$111=6000.000

$112=1000.000

$120=1000.000

$121=1000.000

$122=1000.000

$130=410.000

$131=940.000

$132=200.000

ok

$#

[G54:0.000,0.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

?

<Idle|WPos:-407.000,-937.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

ok

So apparently your machine doesn’t zero-out the origin upon homing. I believe this is normal for the base firmware from factory.

Can you run this command in Console and then return output?

G10 L2 P1 X-407Y-937

$H

$#

?

I thought I had flashed it with newer firmware.

hmmmm

here is the output

Waiting for connection…

Grbl 1.1h [‘$’ for help]

[MSG:‘$H’|‘$X’ to unlock]

error:9

G-code locked out during alarm or jog state.

[MSG:Caution: Unlocked]

ok

Homing

[VER:1.1h.20190825:]

[OPT:V,15,128]

Target buffer size found

ok

ok

G10 L2 P1 X-407Y-937

ok

$H

ok

$#

[G54:-407.000,-937.000,0.000]

[G55:0.000,0.000,0.000]

[G56:0.000,0.000,0.000]

[G57:0.000,0.000,0.000]

[G58:0.000,0.000,0.000]

[G59:0.000,0.000,0.000]

[G28:0.000,0.000,0.000]

[G30:0.000,0.000,0.000]

[G92:0.000,0.000,0.000]

[TLO:0.000]

[PRB:0.000,0.000,0.000:0]

ok

?

<Idle|WPos:0.000,0.000,0.000|FS:0,0|WCO:-407.000,-937.000,0.000>

ok

ok

Great. These values look good.

Can you try the print and cut with the vertically oriented registration marks and see if it now works predictably?

Will do but question.

Was something wrong with the config.

I noticed before when I ran the commands for you that this was the response.

<Idle|WPos:-407.000,-937.000,0.000|FS:0,0|WCO:0.000,0.000,0.000>

However now it’s

<Idle|WPos:0.000,0.000,0.000|FS:0,0|WCO:-407.000,-937.000,0.000>

I am assuming that is Workspace co-ordinate system followed by World or machine co-ordinates.

They appear to now be reversed.

Its funny all this started when I replaced the laser module with the S10 version. Everything went out the window. Very odd.

Yes. The reported WPos (work position) being negative basically makes most modes in LightBurn not work correctly. If you primarily use Current Position this may not have been apparent. You mentioned using User Origin which I’m surprised worked well but there may be things going on that I don’t fully appreciate.

The WPos after homing which is also the origin position now being 0,0 is where you normally want to be.

WPos is Work Position

MPos would be Machine Position. Not sure why but your machine was already configured to report WPos rather than Machine Position ($10 being 0 rather than 1 or 3).

WCO is Work Coordinate Offset.

What’s happening is that your machine assumes that the top-right is origin position. By applying the offset it shifts the origin to lower-left.

That’s odd. Did this entail a firmware or configuration change on the controller to accommodate?

Hey there

Thanks for all your help and the explanation.

No the replacement of the S10 was straight forward. Unscrew and unplug one. Mount the new and plug it in. No other changes where made. Well thats not entirely true, I found some of the config was lost.

This had never happened before so I have to assume it occurred as a result of the laser swap.

That said, it works great now. Even the vertical registration lines work great.

Thank you ever so much.

As for User Origin I never use it. I just was curious if perhaps I should have been. Mostly I use current position. Job to the spot and then go.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.