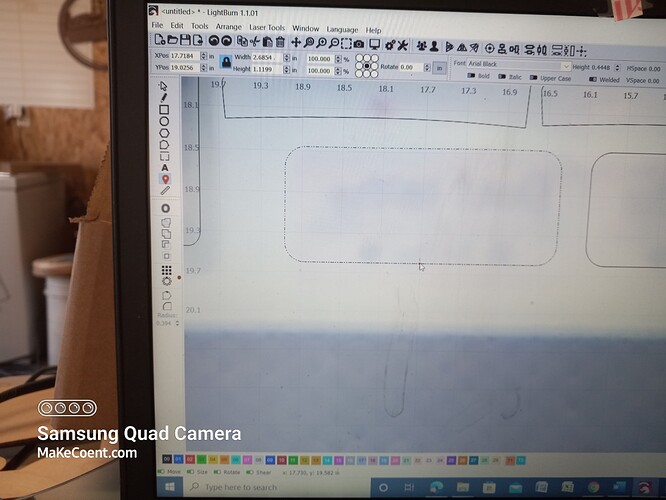

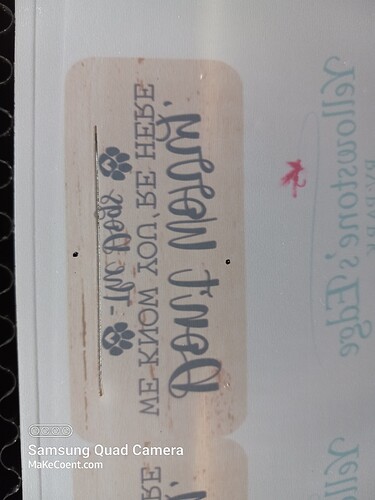

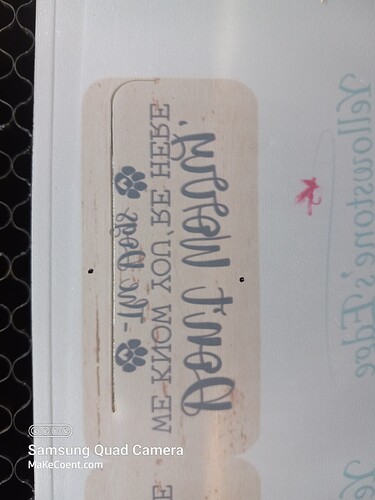

Having issues with the print and cut feature. I’ve set up a file with the shapes and registration marks. Set up the print cut to the points, with scaling. The material is heat pressed acrylic, so there could be a little distortion. In the pics, I’ve highlighted one shape and sent the laser head to the edge of the shape, using lb. The location is correct (black dot in pic) but when i start the cut, the laser moves up and cuts approximately .2 inches above where it should(cut is evident in pics). I can fix the issue if the laser is just off of the mark, but am perplexed when lb sends the laser to the correct spot, then cuts at another spot. This is a recent issue, have cut this material in the same way for the Christmas rush with no issues. Any help is welcome, as I can’t afford to ruin any more material at the price of this stuff.

I do this same process with mdf and have no issues, it is only with the acrylic.

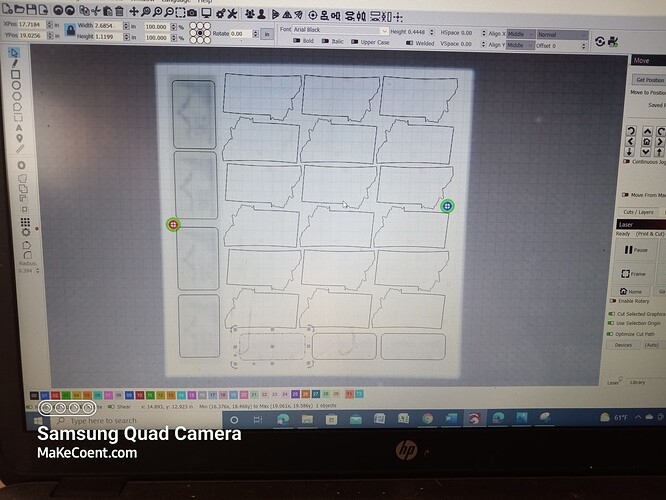

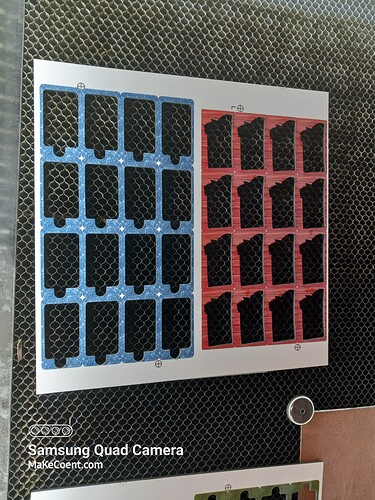

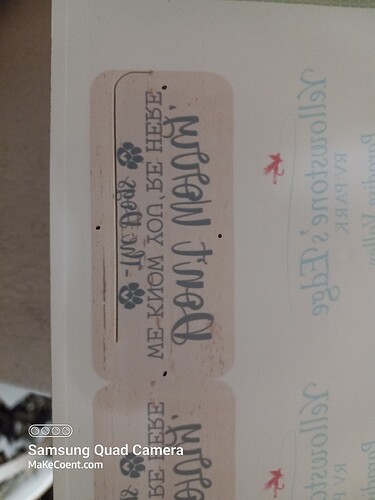

Adding 2 more pics, the 2 black dots are where lb positioned the laser at the top and bottom of the shape to be cut, you can see where the cut ended up. Second is a screenshot of the file.

2 questions that come to mind.

- Are you using Absolute Coords when you do this? Print & cut only works correctly with absolute coords

- How are you aligning the laser head to the target? Do you have a red laser pointer or are you relying on the camera?

- If you are relying on the camera have you adjusted the height of the material to match the height when you first aligned the camera? The fact that this works for you with MDF vs the acrylic makes me think this could be just a material height difference.

Hello & thanks,

-

yes, using absolute coordinates

-

am actually pulsing on the target to get precise location

-

I have a 36"x24" bed, have not been able to get the camera to be very precise, due to the extreme angle of the lens, so only use it to get close. It works fairly well in the middle of the bed, but is easy off in the perimeter.

I use print and cut frequently with mdf, no issues, in fact ran 2 files of keychains yesterday, worked absolutely perfect. I would think it was a mistake in building the file if the cut and location were not in different places.

Just so I’m clear. Are you using the pulsing method to align the laser head to both of the target positions? The ones in red and blue in the last photo? I assume these are where your registration marks are.

If you’re not relying on the camera for target alignment then this rules out material thickness being the culprit.

I assume your workflow is correct since you’re able to get this to work with MDF.

Are the designs you run on MDF and acrylic different? If the file are different then your feeling that it might be something in the design itself could be on the right track.

Have you confirmed that the design that you print and the design that you cut are in fact the same? Or aligned the same?

If you were to cut the entire page would all the cuts be offset the same amount or does it shift at different parts of the design? If it drifts then that could imply that the designs are somehow different.

If you’re willing share the file you use to print and the file you use to cut and I’ll compare the files for any potential issues.

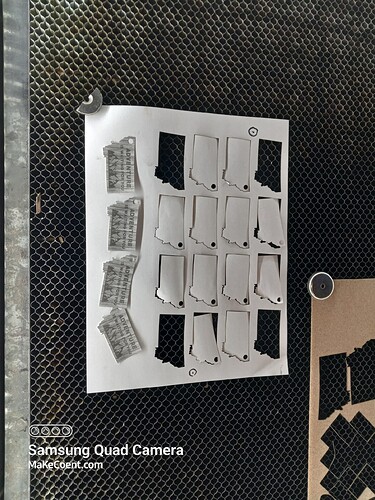

Can share no issue, I’ll attach a pic of the mdf sheets I ran yesterday, they are similar, but not exactly the same. Would prefer to email the files, they contain a client logo, so public share may cause an issue.

Answering further in the questions you asked.

Yes I use the pulse method and yes, the registration marks are the red and blue circles in the photo.

I build the svg and the png at the same time, assuring that the two different objects are aligned. I build the image at least .1" larger than the cut shape, to allow for a small misalignment.

The first file I had issues with, there was a spread between the top and bottom, the top of the sheet, cuts were high and the bottom of the sheet, cuts were low.

The file today is off high and left on all. I could adjust and run it one cut at a time, but when I position the laser head in one place and it cuts in another, I don’t know how to adjust for that.

Was the file from today the same file from yesterday after corrections? Or totally different designs?

Then sounds like these are built to the same scale to begin with. Good info.

If we can rule out any design issues then this still sounds like potentially a target alignment issue in that case. What isn’t making sense is that your process is working for your MDF designs. I can’t imagine this has anything to do with the material itself and we’ve already ruled out use of camera and height differences.

One thing I can think of that could contribute to the issue is the use scaling with the target alignment. If the print and cut designs are to the same scale you shouldn’t need to do that and could introduce some distortion. I can’t imagine it would be enough to account for the difference you’re describing though.

I’ve sent you a direct message on this forum that you can respond to for the design files.

**Was the file from today the same file from yesterday after corrections? Or totally different designs?

** Different designs, different files, but similar layout.

Blockquote

I use the scaling in all of them, the acrylic can shrink a little when heat pressed and sometimes they don’t print exactly to scale(printer operator & software issue) I assumed the scaling would correct for these issues, if not, that may be my issue.

Does the acrylic shrink uniformly vertically and horizontally? Or does it favor one direction over the other? If you were to print a square would it remain a square or could it become rectangular.

Print and cut accounts for scaling changes but not distortion changes. I think you could manually adjust for distortion before the cut if you created registration marks on the print that you could measure. So for example if your 8x8 designs becomes 7.5 x 7. You could use the width and height adjustments in LightBurn to resize your entire design. Then use print and cut alignment to cut to the distorted shape. In this case you could use the non-scaling method since you’ve manually scaled.

Here is another pic of the issue in question. The 4 black dots are pulses on the edge of the shape in lb, you can see how far off the cut is. The pulses were made by positioning the laser head to the edge of the object with the position feature(not manually).

The object is approximately 1.125"×2.75".

The acrylic shrinks uniformly, the images aren’t distorted. I haven’t measured it, but it’s not much, maybe a few hundredths of an inch on a 12"x12" square.

I’ll build my next file with the registration marks evenly spaced, directly across from each other. That way I can easily scale the cuts by measuring the distance between them. I assumed the scaling would adjust for this in print and cut, as the other option is unscaled.

This would make sense for the files that are off different from top to bottom, a distortion or size difference would account for that. I wouldn’t think it would cause the object to cut in a different location, though.

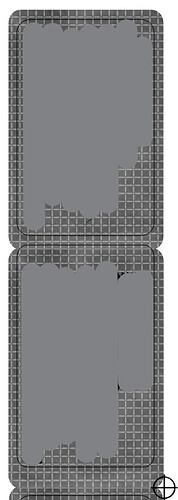

I took a close look at the design files. At first glance they seemed fine but then noticed an issue. But not the same issue as what you’re seeing so curious.

Notice that the cut layer on the bottom shape is set too high? The same issue extends down the design for that column. Everything else looks correct.

This is not where you’re seeing an issue, however.

A couple of notes. Not directly relevant in this conversation but for future reference:

- the father apart the registration marks the less tendency for error. I know yours are quite far apart in real world measurements but something to consider.

- Not sure why but the image file and the svg file seemed to come in at radically different scales. Wasn’t hard to correct but thought that was interesting.

You’re saying that the dots were placed along the cut-line in LB? Do the dots appear where you expect the actual cuts to be?

Doesn’t seem like this would be the major culprit at that level of shrinkage and without distortion…

Are you able to do a print and cut with this exact design on printer paper or something not precious? Would be interesting to see if the issue is repeatable with a material that doesn’t shrink.

Your assumption is correct. This isn’t a problem for print and cut without distortion so should work fine.

I agree… not quite sure what’s going on.

For sure there should be a problem in the design issue I saw but not in the issues that you’re seeing.

That is my mistake for sure.

One difference between cutting the acrylic & mdf I just thought of in seeing your message, it may be of value, on mdf I’m cutting the material from the top, on acrylic I’m cutting the material from the bottom. I’ve been flipping the svg. Would flipping rather than rotating 180 degrees make a difference?

Yes, they are marking pulses I made to check alignment. The dot on the top was the first pulse, I adjusted the shape in lightburn a little toward that direction. The other three dots represent pulses on the line of the shape after adjustment, there is a 5th pulse which would be a little above the the top dot in the pic, between the dot and the cut.

This shouldn’t affect placement if I’ve understood you correctly. It could result in a difference in kerf at the top vs bottom of the material but don’t see any reason it would affect placement like what you’re seeing.

It may be difficult to pinpoint the cause of what’s going on using your regular designs. I think running the design on paper or some other low value material is a start just to see if it’s reproducible on something other than the acrylic in order to rule that out as a variable.

But then after that you may want to create a test pattern… possibly a 12x12" sheet of numbered 1" squares evenly spaced. Then you should be able to accurately measure across the entire sheet what the error is. Will tell you if it’s a scaling issue or just a pure offset issue and make quantifying the error easier.

Something is still bugging me that it works with your MDF designs… so must be something unique to the designs or unique to the material. I assume your workflow is the same for the MDF designs but let me know if that’s not the case. Would be good to narrow down if the issue is in the material, the design, or somehow your workflow.

Yes, workflow is all same process for either material.

I had corrected that alignment issue with the original file of the evening, I just forgot to replace the file. Creation happens in the house on a different computer.

Had a meal to replenish blood sugar and now fully realize the difference between flipping and rotating, lol. Too many hours without eating will do that to me.

Attaching pic of another file that i could print to scale on a regular printer, it ran perfect, all the images are set in the cut shape as they should be. The only difference is the size, this design is half the size of the other.

Normally this would be a good thing but trying to consider where that leaves this… Are you seeing this issue with multiple designs for acrylic? Or is this a one-off issue?

I don’t see anything that would make it unique to acrylic other than the slight shrinkage you noted. Scaling should address that no problem. And if there’s no distortion then that shouldn’t be a factor.

It’s likely not a workflow or process issue since you’ve been able to produce reliably good cuts.

Doesn’t seem like it’s something mechanical again since you’re able to get good results.

Design problem seems to have been ruled out.

There was one other user that encountered a single occurrence where print and cut wouldn’t align for him. I could not reproduce the issue. I tend to think that LightBurn is quite reliable in how this works as long as the right steps are followed but can’t necessarily rule that out.

Some of the @LightBurn folks may have some insight when seeing this but not sure what else to check.

Thank you so much for your assistance! We’ll figure it out.

I have some other files that have the issue, all on acrylic, it’s about 50/50. I’ve fought through them for what was necessary at the time there’s one more that I can’t figure out for the life of me, it’s 16 circles centered in the frame on all sides, equidistant across the whole design, can’t get it to cut for the life of me.

I’ll try this one with the corrected file and fight through if I can, the cutting in a different spot was why I asked for help here. I usually just read some and try to figure it out.

Thanks again, if I come up with anything that I can put my finger on, I’ll post it on this thread.

I haven’t had any luck using the Print and Cut feature. I use the “Position Laser” tool. You can find it under the Tools Tab or use the icon on the left side of your screen. Mine is right under the Text tool. It looks like a map pointer. For a good demonstration on how it works, check out this YouTube video. Making laser jigs the easy way! (Setup time is less than 1 minute) - YouTube. Forward to the 14:50 mark. Maybe it will resolve your issue.