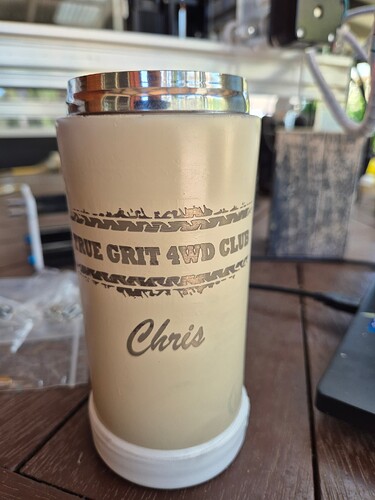

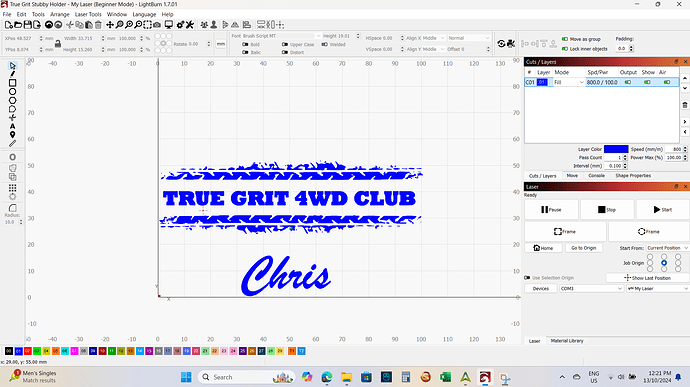

I’m trying to print my club logo on to seperate items. The first is a coffee cup and i have no problems with that. The problem is with the Stubby holder, the image is squished, the Y axis doesn’t seem to work properly. I have attached two images, image 1 shows the coffee cup, and image 2 shows 2 seperate attempts on the stubby holder. PLEASE HELP!!!

What did you change between running the 2 cups?

Absolutely nothing

I can outline fine, but if I set it to fill it buggers up.

Post a screenshot of your entire Lightburn window with the Cuts/Layers Panel and Laser Panel visible.

Did you go back and try it on another coffee cup? Put tape over the original and lower the power if you do not have a spare cup.

Yep, tried all that. Same result.

Only thing I see is that your rotary isn’t enabled. That may be because you’re doing flat work and just opened the file to show. If not, that may be your problem.

Also, I recommend turning off Beginner Mode. There are several things that you can’t do in beginner mode.

How do you work out the ‘mm per rotation’ in the setup of the rotary? Brain not working. Is it Pie x Dia?

Your rotary manufacturer should have given you some guidance there. Without knowing what type or model of rotary you have I can’t offer much guidance, but I’ll try. It’s a combination of your stepper motor in the rotary and the steps per mm of your laser and the diameter.

If you have a roller rotary, not a chuck type, tape up a tumbler real good. This works best if you have a straight sided rather than tapered tumbler or a rolling pin is probably best. Make a rectangle in lightburn 100mm long by 10mm wide, the width doesn’t really matter, it’s the length we’re working with. Set your output to line mode with a low power and low speed. You want low power so it doesn’t burn through the tape and you want low speed to avoid slippage.

Pick a number in rotary setup for steps, lets start with 50. Run the file and measure the output. If the burned rectangle is 100mm, you’re golden, if it’s anything other than that need to adjust the steps and run it again.

If it’s 200mm, change to 25 steps, if it’s only 50mm, change to 100 steps. Continue adjusting the steps and burning the rectangle until you get a 100mm rectangle. Those are your steps for that rotary on that laser and should never change.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.