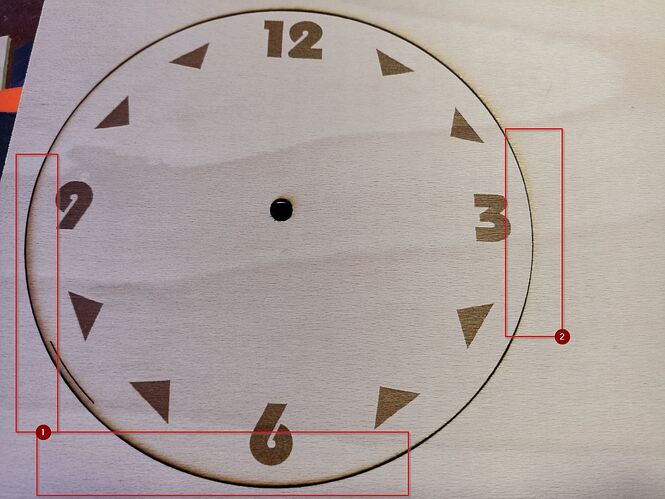

Hello, I am solving the problem that when cutting angles, in some places there will be a wider cut and the edges of the cut will be tanned, see. picture, point 1. In contrast, in point 2, cuts fine. Would anyone advise how to prevent this?

This is a cut of beech plywood, 3 mm, at a speed of 220 mm / m in 4 passes. The laser is a Sculpfun S6.

First question is why are you trying to cut anything at 220 mm/sec? I don’t know what a Sculpfun S6 laser is, but to cut 3mm ply with my 80 watt CO2 I’d be testing starting at about 10-15 mm/s to cut in one pass.

Your one/two variation looks like a classic example of the beam losing focus due to either a warped workpiece or an out of level bed. Can you check that?? Cheers & luck.

The Sculpfun S6 is a laser diode engraver. The power level is much lower than the lightest available CO2 lasers. The frequency of the light is visible instead of Infrared so there are many differences in behaviour and settings between this and a CO2 laser.

The speed setting is 220mm per minute (3.67 mm/sec). It’s more common to use ‘per minute’ units to have better control over the low power engraver. It allows grayscale, norton white tile and other fine work to be more readily finessed.

You’re right with this and the workpiece can buckle as it’s being cut. The bed on this model of engraver is a tabletop or workbench.

It’s hard to say for certain what is causing the differences in cut performance in this specific case but there are a few tests that may shed some light on things. ![]() (sorry - I had to…)

(sorry - I had to…)

Laser diode engraver dots are not always square or round. Some are rectangular and cut better in one direction. The test for this is to cut a right angle triangle to compare the cut behaviour in the x-direction with the cut behaviour in the y-direction. You may see a pronounced difference between the cuts on the two axes.

The grain structure of the wood can respond to visible light differently as well. Turn the wood 90 degrees and repeat the triangle test and see if the problem changes.

You may be able to cancel out part of the combined effects of the grain structure and the shape of the laser diode dot by rotating the wood.

Flatness and focus are other factors. You may also find that the wood will bow and make popping noises as the cutting releases mechanical stress. ( I experienced this on a door-skin that I cut with a diode laser.)

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.