Hello colleagues, I read on the forum but what I found related to my problem, the topic was closed and the answer in the topic did not help me so, with the admin’s permission I will repost this problem to the sky I hope to find the solution through the forum community. I received from someone a 60 W Julong Lasercutt that was in a fairly advanced state of degradation and full of rust. I started trying to put it back into operation and in addition to other problems I found that the work table goes down about 10 cm and although I keep the lowering button pressed, at some point the motor changes direction by itself and the table goes up to the upper level. The same thing happens if I press the lifting button, when the work table reaches the maximum upper level, the motor automatically changes direction and goes down… If I keep the button pressed, the cycle repeats… Is there any setting related to the upper and lower limits of the work table that I need to modify? or what could be the problem? If you have any idea please try to help me. Thanks in advance to the entire community on this forum!

Hi @Bigboy1967

What you’ve said points to hardware. A couple of things to check:

- Have you adjusted any controller settings related to autofocus? On some machines, if autofocus is enabled but the probe or switch is faulty, the Z will “hunt” instead of stopping.

- Many machines of this type may have a limit switch at the top of Z travel, sometimes both at the top and the bottom. If one of those is stuck, rusted, or wired wrong, the controller may see it as tripped and reverse the motor instead of stopping.

- Some setups also use the autofocus switch itself as a Z-axis limit — if that’s dirty or failed, you’ll get the same cycling.

This almost certainly isn’t a software issue, it’s wiring or switch logic on the machine. If you can confirm whether you have separate top/bottom switches and whether autofocus is enabled, that’ll help narrow down which switch needs attention.

Can you also confirm the controller type in use? There are some handy diagnostics for limit switches on some DSP controllers.

Thank you very much for the answer. The truth is that I am at the beginning of using this model and, in addition, as I wrote, I want to fix it. I will study the problem and take into account the advice received, then I will come back.

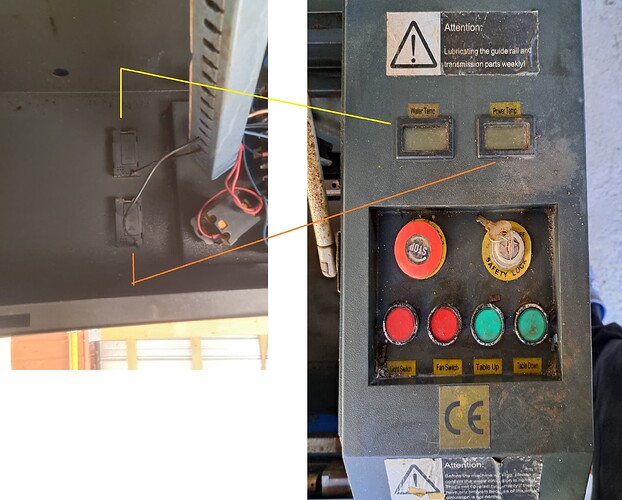

I can not say anything about the focus because I also have a problem with the metal part of the laser tube that I will try to glue with J-B Weld at the suggestion of a college on this forum. What I found when raising/lowering the work table was simply a finding of the activation of the control buttons of this thing.

Depending on the evolution of my works, I will come back … this is how the device looked immediately after I received it, now I have just finished cleaning and oiling/greasing it. I will try to post some pictures.

Once again, thanks!

Hi @Bigboy1967

From the photo this looks like one of the common “blue/black box” CO2 lasers. In its stock form it uses a Nano2 / M2 Nano controller, which unfortunately isn’t compatible with LightBurn — that board only works with the bundled LaserDRW software.

These machines also usually don’t have proper limit switches or homing. The motion buttons on the front panel just jog the head manually, so the controller itself has no sense of position.

If you’d like to run LightBurn, the path forward is to replace the controller with something supported. The best upgrade option is a Ruida DSP controller with built-in stepper drivers, which adds proper homing, safety features, and full LightBurn DSP support. Alternatively, you could go with a GRBL-based board (simpler and cheaper, but generally requires external stepper drivers).

Either route will normally involve adding limit switches so the controller can home and manage coordinates correctly. If you like electronics and tinkering its a good project.

p.s. if the last photo is the end of the laser tube, I’d recommend replacing it.

Hi@Dominic !

Yes, indeed my 60W (CO2) Julong laser is an older model exactly of the “blue/black box” type and it is in its standard form and as far as I can tell it uses a Nano2 / M2 Nano controller and I think the software used is LaserDRW, the person who donated it to me also gave me the USB-dongle that this device works with.

I received it in a pretty bad condition and I am trying to reactivate it, I cleaned it, wiped it and then greased it and the 60W laser tube has the metal cooling part detached from the end. I realize that this defect would require me to replace the laser tube with a new one, but since I found colleagues on the forum who did this repair, I will try to glue it myself because first I want to figure out if I can make the entire device functional and I hope that with the help I received from colleagues on this forum I will succeed in this.

I have had a 40W China laser for a few years that I improved over time but with which I was unable to cut 2.5 mm thick birch plywood (for model making) and now that I was offered this 60W device I decided to try to repair it.

For the 40W Laser I bought the necessary equipment to upgrade it with the Trocen AWC 708Lite Controller and I purchased the motor controllers, but I did not have the necessary knowledge to make this transformation, but I have not given up on the idea yet … maybe, if I manage to put this 60W laser back into operation and if I find someone who will have the necessary patience with me to explain it to me, I will be able to make this upgrade to the 60W laser.

Now I’m waiting to receive the ordered J-B Weld solution and try to repair the tube to see if the device responds to basic commands and if I’m successful, I’ll continue trying to bring the device back to the best possible parameters by making other necessary upgrades.

Speaking of repairs, I saw that the displays (from the laser) that indicate the water temperature and “Power Temp” each have a black wire on the back … is that OK? shouldn’t there be two wires for each digital temperature indicator?

Thank you to my colleagues and the entire community on the forum who are trying to help me and have the necessary patience with me!