Hi, Everyone.

Thankyou for your previous help.

I have a new problem. Originally I was getting two dots on the tape in the first mirror. The one directly after the laser tube lense. The machine is very weak when doing cuts, even when the power was increased.

When doing the pulse test, by pressing the pulse button there would be nothing, unless I held the pulse button down for 5 seconds then it would create a mark on the tape.

Looking at the tube at the back of the machine there seems to be purple light but it is flicking left and right.

Has anyone seen this kind of behaviour before? Is the tube knackered?

Thanks

Ian

Unfortunately, I think so.

Hi bernd.dk,

Thanks for the reply I posted a video link of it in action for everyone. Was hoping it was something else before committing to purchasing another tube.

I am based in the UK, anybody know a good company to purchase laser tubes from/

The information on the tube is as follows:

co2 laser tube model F4

Peak Power 120w

Rated Power 100w

Serial Number 276-1119-065

It is not the video that supports my opinion, but that you have to pulse in 5 sec. At M1 you should always get a brand mark after a few milliseconds if you are spot on.

What is powersetting in your video? And you have hold a piece of wood in front of M1 to make sure you hit the mirror?

Yes it used to…I could quickly press the pulse button and it would create a dot.

In your opinion would you say the tube has gone? Could it be a power issue?

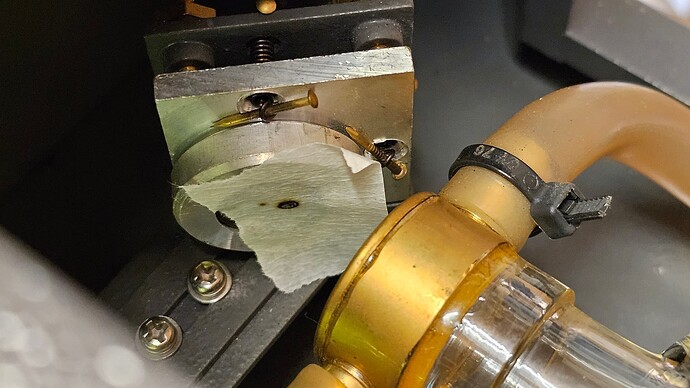

This is the view of the mark it made but after holding down the pulse button for 5 seconds. It would not mark it with just a single press of the button.

The power Setting was at 20 percent max and min.

Even when trying to cut a circle in lightburn I increased the power to 50 percent but it just made a very light circle…

Stop a little that the laser beam flows round this way does not mean that the tube is broken! But if you use 5 Seconds to make this spot …, it is not in the center but anyway there should be a quick firemen on tape. - What does your ampemeter say?

Hi bernd.dk

Thankyou for your help in the previous comments. I now have a new problem.

It seems.

I was wondering if the phenomenon in my laser tube is normal? When I fire up the machine I do not see water circulating around the spiral glass coil part of the tube near the high voltage end. The tube laser is firing okay, but I do not want to continue using it as I have spotted this. The water is coming out the outlet nozzle back into the water box where the water pump resides, so I assume the pump is working ok. Is the tube knackered? or can it be fixed?

Also when the machine is switched off the water does not seem to drain from the tube.

Please see attached video link.

Is it possible that someone can upload a video of their co2 laser tube firing up for comparison, especially the glass spiral section near the high voltage end.

Your aquarium pump is just too weak for the task. There must be no air bubbles in a co2 laser tube. It is wise of you not to drive with this setup.

Hi bernd,

Thanks for the reply, there is water coming out the outlet pipe back into the tub, as you can see at the end of the video.

Does this still mean the pump has given up?

I have a 100watt co2 laser tube and was thinking about getting a cloudray water pump.

Like in the following link, do you think it would be suitable?

Cloudray 80W Water Pump – Cloudray Laser

I myself have had different pumps for my old K40 with 35 Watts. After a relatively short production time, it was necessary to add ice cooling blocks to maintain the temperature. For my 60Watt OMT, I have bought a real cooling machine CW5000. It maintains temperature and pressure. It is thermostatically controlled and starts approx. every 5 minutes. In my opinion, this is the most correct way to cool your laser. There is also a cheaper variant, I think it’s called the CW 3000, but it doesn’t have a compressor and only cools to ambient temperature, it’s just not enough, in my opinion.

Your problem seems to be that your pump can’t pump enough water around, the pressure is too low to fill your tube. You could reduce/clamp the output of the tube, but that is not the right way to solve your problem.

Hi bernd,

Are you sure it is the pump? i have been using the machine with this pump since purchase, are you sure it does not have anything to do with a leaky tube or something to do with the flow regulators on the machine? I have checked for leaks but cannot find any.

I have tried pinching the inlet tube to create additional pressure but it does not improve the situation. When I look at the tube from side on it is as though it is only half full. Yet as mentioned before there seems to be a steady flow of water coming out of the outlet hose into the tub.

What is your opinion regarding the cloudray pump I linked earlier?

Shall I purchase this and see if that solves the problem?

Thanks

We all use things until they fail, it means something broke… past use is no guarantee.

I guess this proves it’s not a leaky tube…

The only flow regulators are where you bend/kink the tubing and the pump itself.

Sometimes we can’t afford test equipment, so you have to use what you got.

I assume that you visually checked and you don’t have any radical turns or routing of the coolant lines …

I’d suggest comparing, by eye, the output from the tube – remove the supply side and see if it’s any better. If there isn’t a noticeable difference it’s unlikely any kind of flow restriction…

As @bernd.dk pointed out there is no way to imagine how nice a chiller is. Wire it up to your Ruida and you have flow and temperature alarms for the machine. Not to mention no more messing with ice and being glued to a thermometer.

Besides that, the coolant should be isolated from any air contact. It will pick up small pieces of debris when it’s in a container with even a small opening.

The most important is that the coolant have a high dielectric constant. We’ve seen it where the anode (high voltage) arcs to the coolant, because of higher conductivity and that makes anything metal and touches the coolant be at the anode potential. A chiller isolates a good coolant and keeps it clean.

Well, that’s the best idea… however I ran mine, like this, for over a year with bubbles because of the glycol I used to prevent freezing. It foamed up after passing through the pump propellers. I actually sent this video to Sadler in GB and asked about running it like this… he said no problem, so I did.

He did mention, what you don’t want… that is any kind of a bubble that sticks to the inner tube that you are trying to cool. So if a bubble is stationary or that actual lasing tube doesn’t have coolant flow completely around it, it’s an issue…

I’d suggest tilting the tube to see if it will naturally flow out… But by your own admission it worked before…

Good luck

![]()

There is not much to add.

As for air bubbles, I’m a bit injured. We fought a hard battle against pitting which has “eaten” quite a few cylinder linings on our Caterpiller gas engines. They were large 12 cylinder marine engines which were converted to natural gas for our power heating plant. Our American colleagues found out that high-frequency vibrations were to blame for the fact that there were air bubbles in the cylinder walls/cooling system, which exploded during extreme overheating.

All cylinder tubes/linings were changed in construction and replaced.

That’s why I hate air bubbles in cooling systems.

If the laser tube is turned and lifted so that the water outlet from the glass to the hose is highest/forms the highest point in the system, you must be able to fill your tube, regardless of water pressure and water flow. (the cooling effect will still not be good enough with your pumps)