Hello everyone,

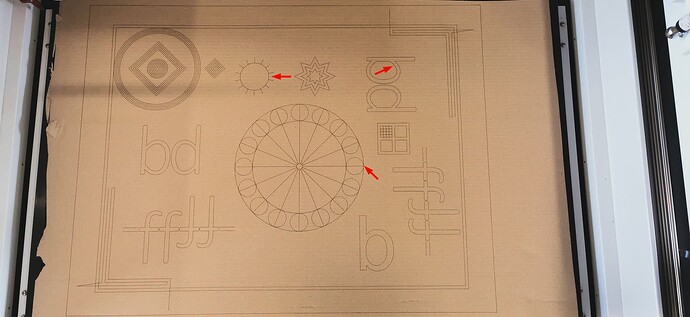

I wanted to engrave a larger Prokjet with lots of buttons and then cut them out.

60 round tags.

The emblem is the same on all the tags and there is also a number from 1 to 60.

I had 4 rows of 15 buttons each.

When I had finished engraving and cutting them out, it hit me.

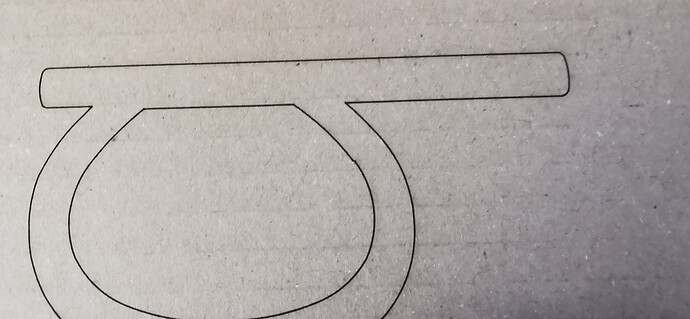

Because the inner plates were all scrap, I could only use the outer ones. The engravings on the inner ones were offset, so they were double images.

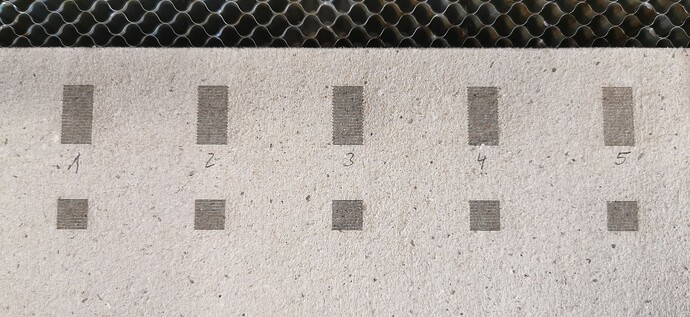

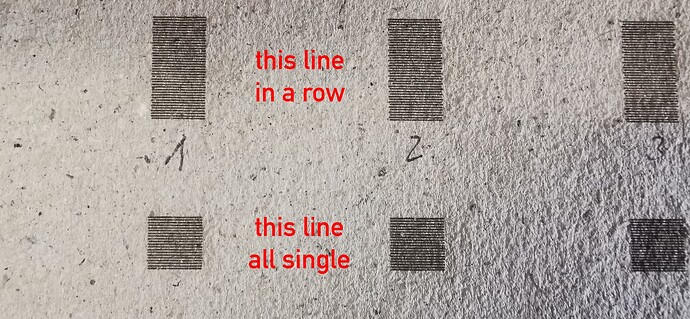

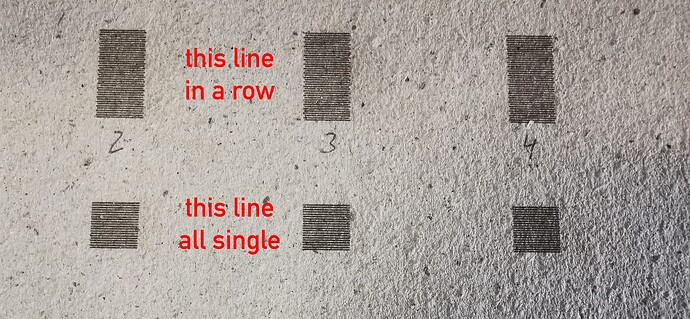

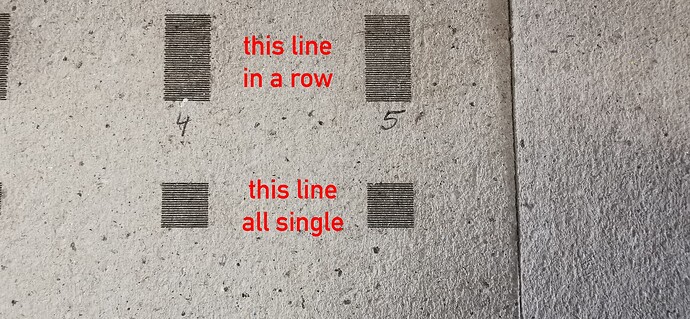

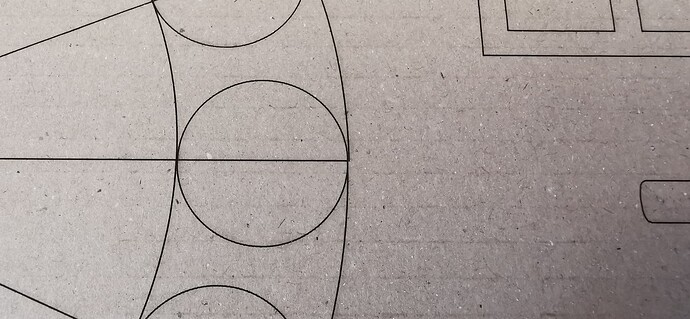

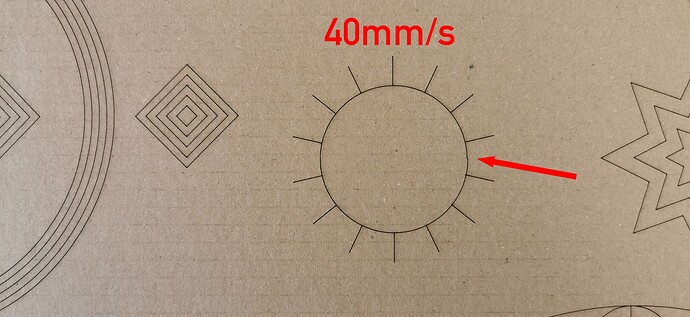

Then I started searching, filled squares with a line offset of 0.5mm so that you can easily recognize the start and end points of the line.

The first square fits, the second no longer does, the third is even worse and the last is okay again.

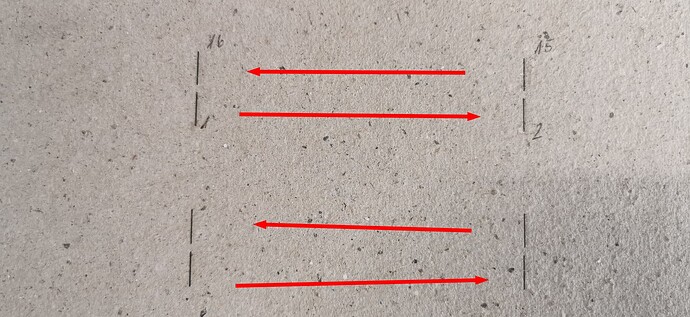

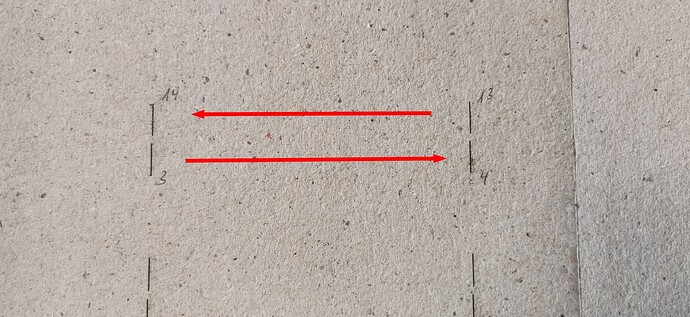

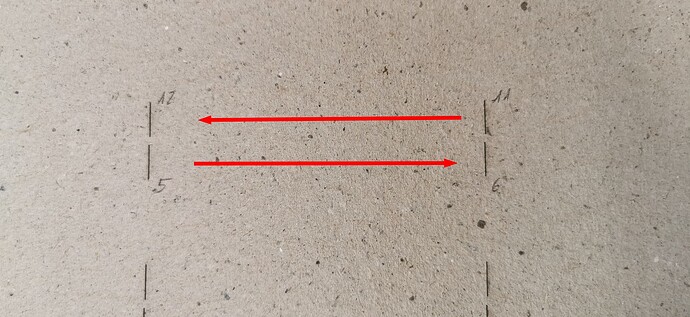

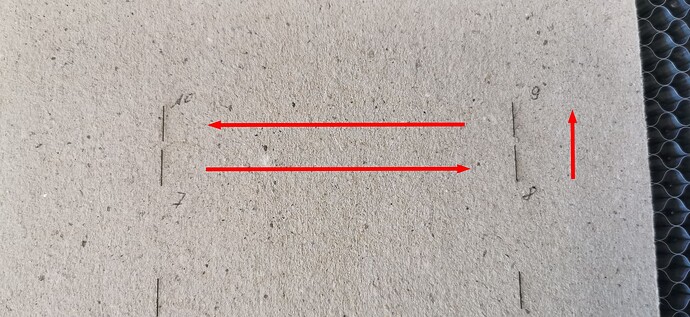

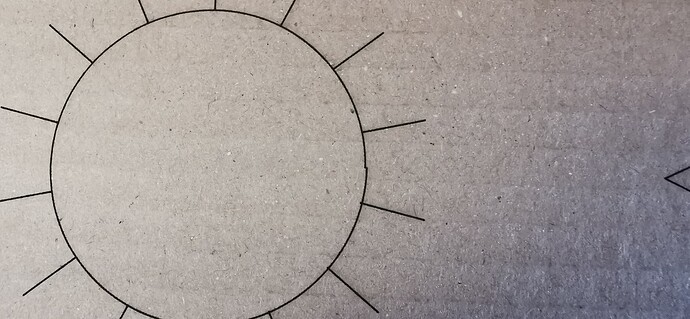

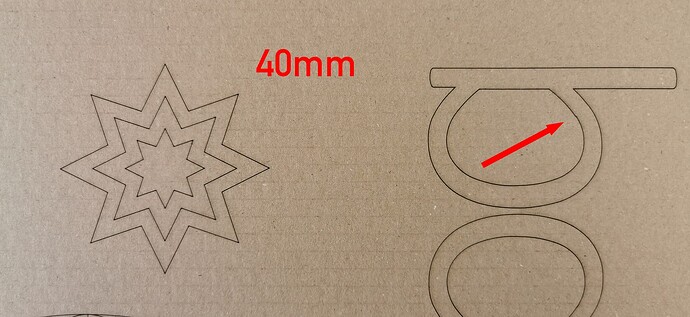

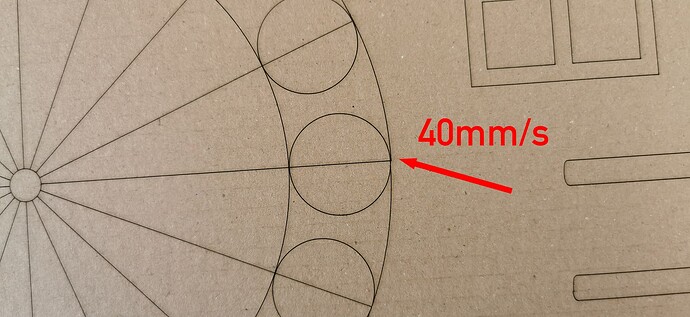

I then drew 10 mm long lines at a distance of 100 mm 8 pieces, my laser has an area of 900x600mm.

I then copied the lines and placed them underneath.

I then had these lines cut from left to right and the top row then from right to left.

Here, too, the first lines are in the same position, as are the last ones, but the others have an increasing deviation up to the middle and a decreasing deviation from the middle onwards.

I just can’t explain where this offset suddenly comes from.

Above all, why doesn’t it all fit at the beginning and end and in the middle?

If I have the 10x10 boxes engraved individually, then they all fit, but if it engraves them in a line, then they don’t.

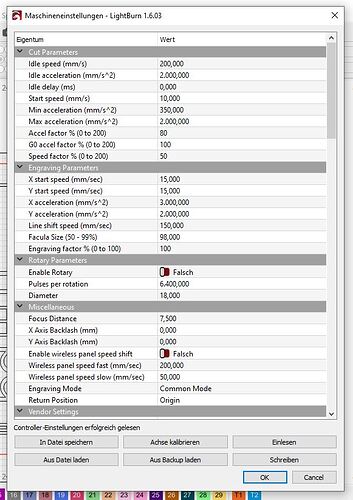

I have already made the acceleration so slow that it must have used 100mm right and left for braking and accelerating, but the result is always the same. I only engraved at 300mm/s. But even with 400 and 500 I have the same phenomenon.

Do any of you have an idea where I should look?

If the start and end are correct, regardless of whether I am engraving or cutting, then there can be no problem with the mechanics, or am I on the wrong track?

A few pictures to show what I mean.

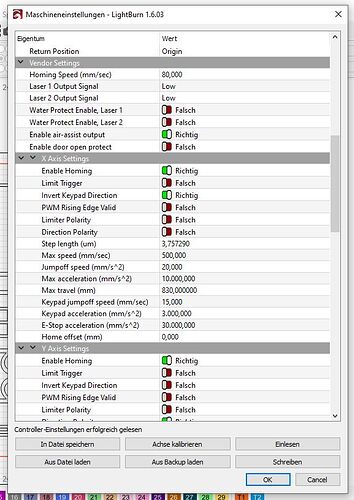

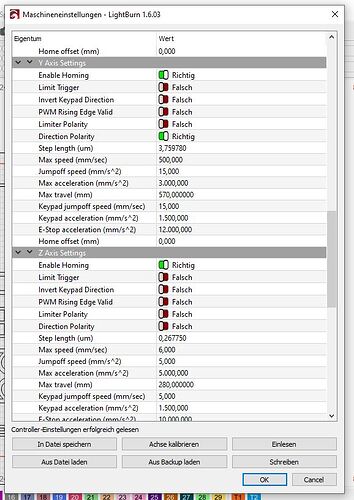

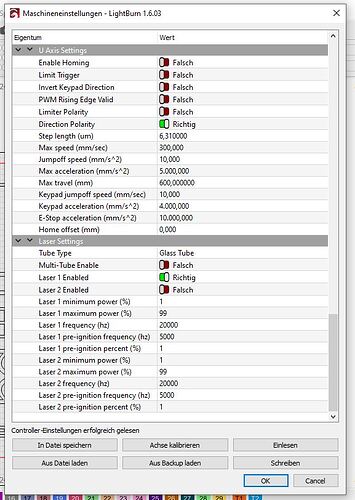

My laser is an DLW9060 China import with Ruida RDC6445S(EC)

Leadshine 3Phases motor drivers 3DM580 and NN-Motors 3Phases stepper motor.