Variations in materials and paint thickness is likely responsible for the hit-and-miss.

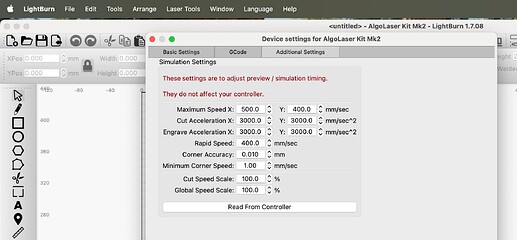

The time estimate is provided by a simulation and not directly from the controller. It’s a solid estimate. The simulation settings are under ‘Edit’ then ‘Device Settings’. When the estimates are off, it can be caused by an incorrect setting or an unexpected controller behavior. The settings can be fiddled with to produce adequate reults.

There is no precise formula. Generally, the behavior is ‘Linear… within a range…’. and the 10,000 per 10% might work between 60-90% or between 30-70%. It certainly might not work anywhere. It really can’t be known without testing.

It’s possible that 3000 mm/min and 30% is on the lower power limit of your engraver for marking your material. This can exaggerate the hit-and-miss behavior you’re reporting. The material test is the key to getting the speed and power settings that you need.

The material tests are key. The most noted contributor to tile engraving, Nicky Norton posted a picture a couple of weeks ago of a large pile of discarded test pieces in a plastic tub. If you want great results for one piece, you should expect to consume a minimum of 3-4 identical pieces in testing. Testing, marking up and discarding perfectly good material is the only way to get there.

These may be true but they’re absolutely machine-dependent and material-dependent. Material testing with your machine and your material are the only way to optimize. Recommendations from others may guide you where to begin your material tests but that is all that recommendations from others can ever be.

Going slow and turning the power down can shrink the dot size and enhance the detail. Most of the best tile engravings are done with a lower-power laser. These highly detailed tiles made with low powered lasers take a long time. The ability to pull detail may be limited by the larger dot created by a 20W laser.

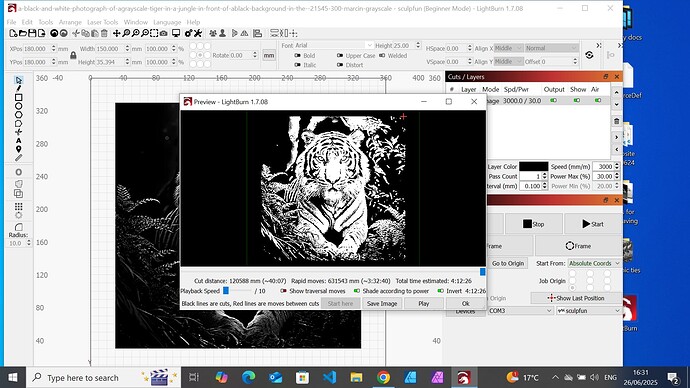

In the screenshot you’ve shared, the first thing I see is 'The Penalty of Speeding Up". The engraver spends time accelerating and decelerating after each line so it can change direction. It’s travelling almost three times further to slow down and stop and come back up to speed than it is travelling to engrave and produce the art. Acceleration is limited by machine rigidity. If the Force (mass x acceleration) causes the machine to deflect, it will mess up the engraving.

The preview is showing 3:32:40 (~3.5 hrs) of Rapid Moves. This is the time spent changing directions. If you turn on the ‘Show Traversal Moves’ switch in the Preview window you can see the Rapid moves (In Red), and any other non-engraving moves like the move from your ‘Start From’ to where the engraving begins.

The total estimated time is 4:12:40 (~3h 30m + 45m). The engraver is engraving for 45 minutes.

If you cut your engrave speed in half, the amount of time spent with Rapid moves should be halved (~1h 45m) or less.. The engrave time will double to 1h:30 but now you’re down to ~3h15 from ~4h15.

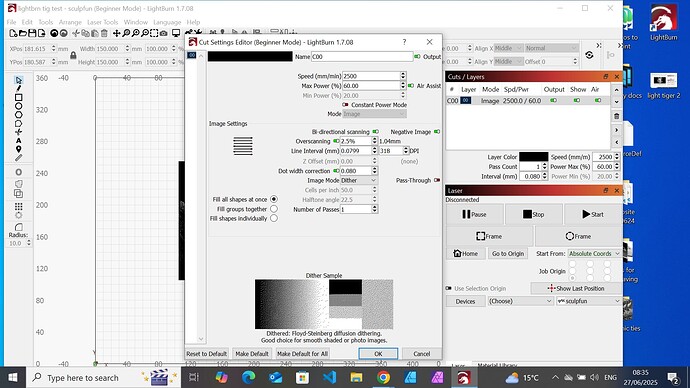

The next target is ‘dot size’. Most people believe that 600 dpi or more is great but the reality is, the engraved marks from the laser are more like drilling holes of a specified size. If you stack the holes too close together you just get one bigger hole. Folks will throw away all the contrast that would be available to them by not leaving enough space between the holes.

For the next step, pop open the Cuts / Layers settings and capture the screen to share it like you did previously. I’d like to know what was selected for Line interval or Dot size. Increasing the dot size or Line interval slashes time off both the Rapid move and Engrave move totals. It also enhances detail by not piling all the holes on top of each other.