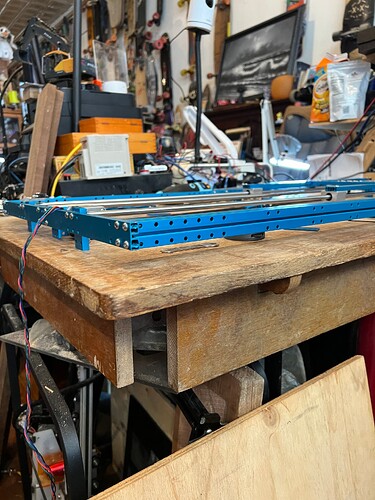

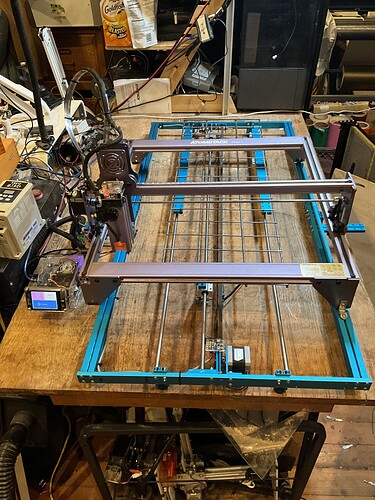

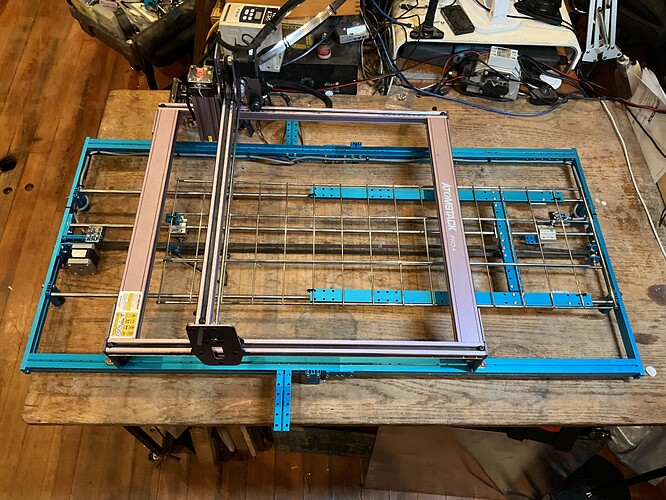

I decided I wanted to make a shifter (conveyor) for my projects and took some spare material I had running around and built one. I need to finish the electrical, I am currently trying to decide which plugs I will use for the stepper motor and limit switches to simulate the y axis but it looks like it is adding about 500mm in length. I can add it to any of my lasers as well as my cnc router.

Looks good!, Is this so you can quickly and accurately extend the Y-axis when needed for an oversized job? What do you mean by “simulate the y axis”?

Regarding the y-axis, you should just put the same plug as the other lasers have, since you just replace it (like connecting a rotary).

The limit switches can be connected in parallel to the old ones, if you constantly switch between lasers, I’d build some Y-adaptors to take the normal limit switches and your extension switches when needed. The laser does not care where the signal comes from as long as one is coming.

it will literally move the material beneath the laser gantry allowing the working of material over doubling the length to about 900 mm of material. I have some glass panes I want to do some landscape etchings of that 36" long so I figured this was a great way. The stepper that controls the y will be unplugged off the machine be plugged in on the slider

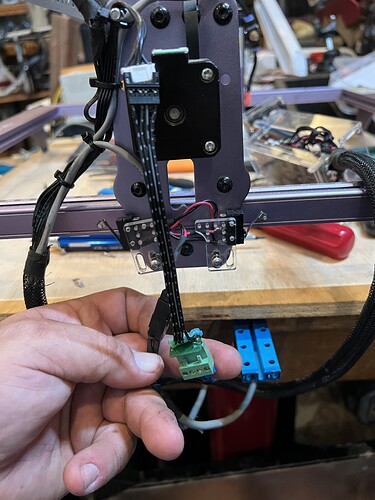

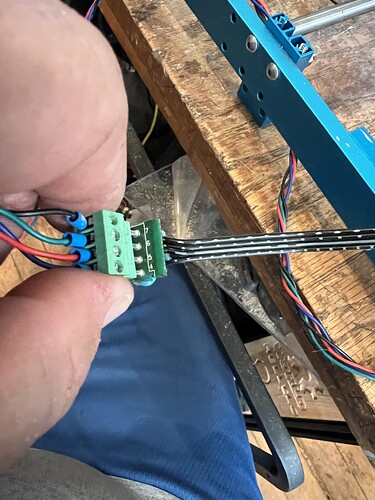

that is what I am thinking on the stepper as the one on the slider is a green pin plug and the machine runs a normal servo plug, I am thinking Ill use the harness I have for my roller and do some work with it. And the limit switches I have on the machine are simple spade but I have some other inline plugs I can add in, the y cables are a great idea anyway. I am getting one of the ikier 48 watt units so some of my plugs will change next month but it’ll be easy enough

Nice!, although I am worried that the platform + the glass you want to put on it may be quite heavy for that bed-slinging setup?, is the motor the same as the one on the laser? You might need need to reduce Y-axis acceleration setting at the machine to compensate?

already figured on slowing down y if necessary by adding another profile in lightburn

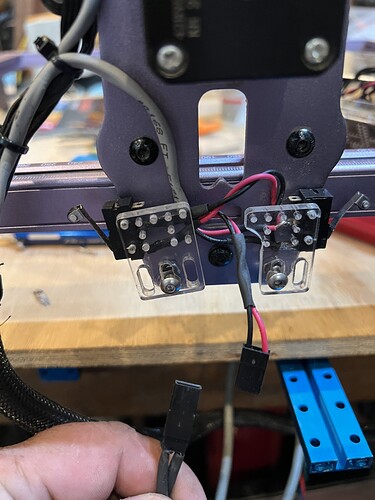

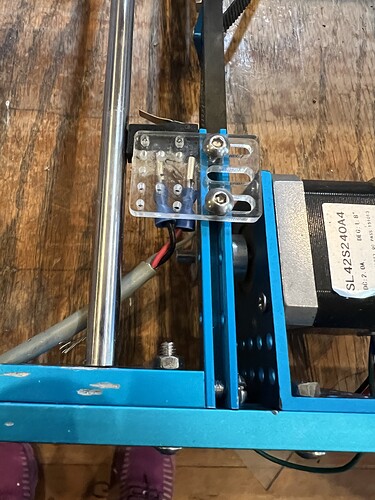

Here is the plug system I came up with, cut up a circuit board for the green pins and soldered to it for the adapter and when doing the plug for the limit switches was an opportunity to add a second on the y axis on the machine too so it was a good bonus.

Location of limit switches, and some coaster wheels made with som double bearings to help handle weight and uneven loading

This shifter gives me 810 mm of usable area with over a third of the area. Video included Shifter video

How is the progress? (Any update on the build?)

it is finished and works well my smaller lasers have not needed it yet for the 48/24 or the 2 watt infared