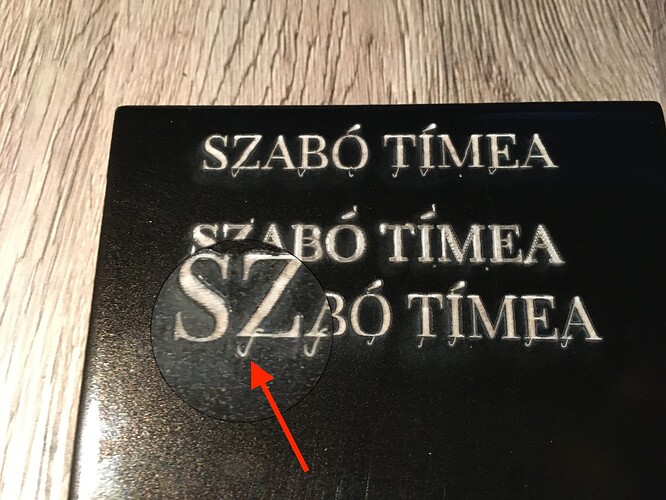

Hello! I have protruding extra lines on my text engrave (on black painted tile with 900 mm/m speed and 70% power):

The image shows 3 trial:

- Imported vector shape

- Imported vector (with 90 scan angle)

- Imported raster image of text

The error still occures, and it seems that the position of the extra lines are staying the same. Any ideas what could cause this behaviour?

Can you upload the .lbrn file you used for this? I’d like to check the laser path.

Sure, here it is:

text.lbrn2 (30.8 KB)

Here’s what I think is happening.

- I suspect your laser module is not well secured to the gantry. If you push the laser module forward and back against the gantry, is there significant movement? If so, use the eccentric nuts on the wheel shafts to close any gap between wheel and rail. You want to eliminate any gap but don’t overtighten as that can cause binding and other issues.

- You don’t see the tail on the first letter S because it’s likely positioned well enough where this isn’t a problem.

- However, you see it at the starting point of each subsequent letter when the laser module moves rapid from the top of the previous letter to the bottom of the next letter.

- Because the laser module is flexing at this time it’s not in the proper position when the laser restarts. This is when the tails are being formed.

- Once the laser settles down from the rapid movement things seems mostly okay.

If the laser module is not loose, then I’d suggest checking if the lens is potentially loose. That could cause similar issues.

There’s also the possibility that this is from backlash along the Y axis but that doesn’t seem as likely.

Thanks for your quick reply and suggestions!

To be honest, my lens are noticeably dirty, I was never able to clean that because the lack of isopropile alcohol. Don’t worry, I have already ordered some

When I get it, I will do an entire cleaning and see if that solves the issue. If not, I’m going to check my belts and tighten them if needed.

I’ll let you know how it worked out. Cheers!

1 Like

Cleaning the lens solved the problem. Thanks for your replies.

Cleaning the lens resolving it? That seems unlikely. The issues you were seeing were almost certainly mechanical, not optical.

Is it possible that the lens had been loose in the module and while cleaning the lens that you resecured the lens or shifted the orientation in some way to reduce movement? That seems like a possibility since a loose lens can cause this type of thing as well but I wouldn’t have expected that much movement in a diode laser.