Once it is set, the laser moves outside the drawn line so the edge of the kerf is at the drawn line location. So if you have a 1" dia circle, the laser path is offset larger so the edge of the kerf maintains the 1" dia. The hole left in the scrap is 1" plus twice the kerf in diameter. This all is good, but what about interior cuts? Does the software somehow figure out what are inside cuts? If you want a 1" OD washer with a 1/2" ID, does the cut on the inside shift to leave a 1/2" diameter on the washer, or do you need to put the inside cuts on a different layer and set a negative offset for the inside cut layer?

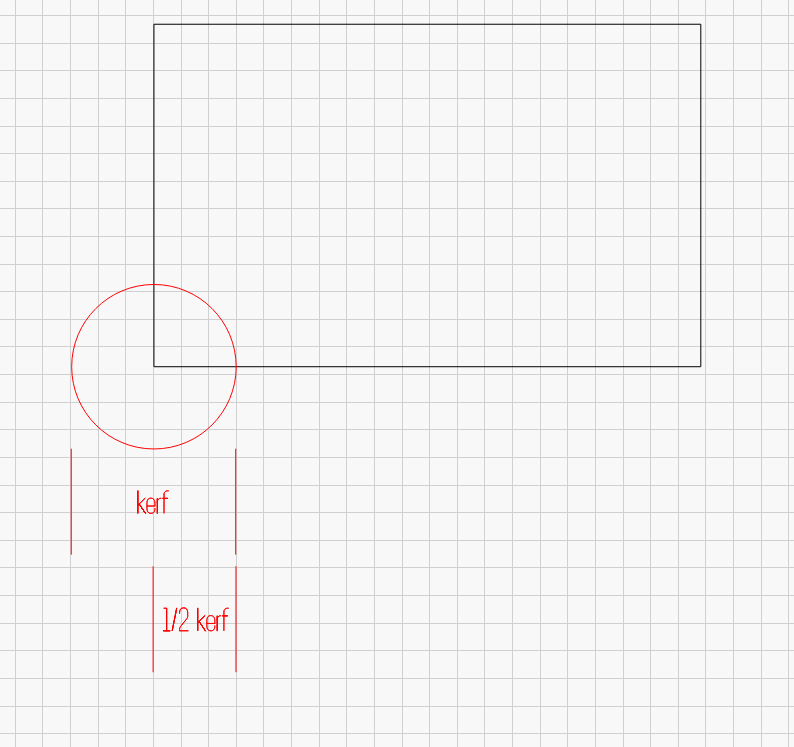

When you draw a box, that line is the tool path.

If your tools kerf it 1", then it will remove 1/2" (1/2 the tools kerf) from each side of the tool path.

A 1/2 kerf offset will move the tool outward (generally speaking) 1/2", in this case and the tools ‘edge’ will follow the tool path since the center of the 1" tool has been ‘offset’ from the tool path by 1/2".

Lightburn is usually smart enough to know the ‘inside’ and ‘outside’ when you apply it to a ‘hole’… You also have to have a closed object for offset to be applied…

The ‘tools’ (laser, saw… whatever) is red the tool path is black… the center of the tool will follow the tool path…

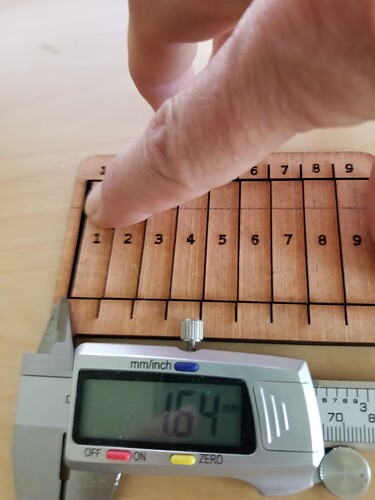

I use this template to determine the kerf of my laser on different materials…

kerf-master-00.lbrn2 (94.1 KB)

There are 10 cuts… so don’t forget to divide the measurement by 10…

This one read 1.64mm so the kerf is 0.164mm here.

Make sense?

![]()

I believe that is what I was saying. My question was does the kerf work the “right” direction for an inside cut? I did the kerf test already, if I remember the numbers, my kerf was .0066 or so…( Would have to go to the shop to see what it actually was.) So, with the kerf at .0066, the offset should be half that or .0033.

It would be 1/2 the kerf… yes.

With a compound lens on my co2, I can make about 0.05mm spot. So there is no way I can get a kerf of less than 0.05mm…

How are you getting a beam that small?

The material I’m using is mdf in the photo and the kerf it 0.164. (2" lens).

![]()

Whoops… upstairs, late at night, misremembered the numbers. Measured kerf is .0068", or .173mm. This is in door skin ply (about 1/8" thick), and 1/16" balsa wood. Laser is an XTool D1 20 watt diode.

Old American engineer trying to get used to metric…

Completely understand…

That kind of an miscommunications caused us to lose one of the missions to mars… the European Space Agency used metric and we used Imperial… end result, crashed into mars…

I was promised a half century ago we’d switch to metric… I have but still waiting for the rest of the US and the UK …

![]()

Wasn’t that the Beagle lander? Been a while, not sure I remember correctly.

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.