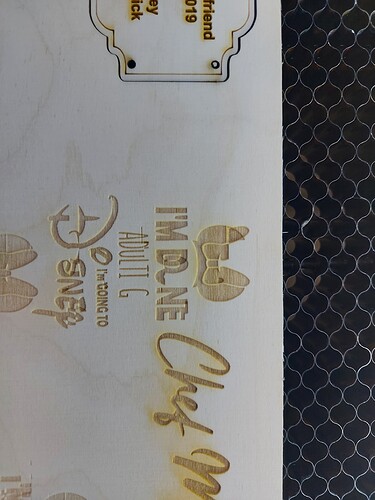

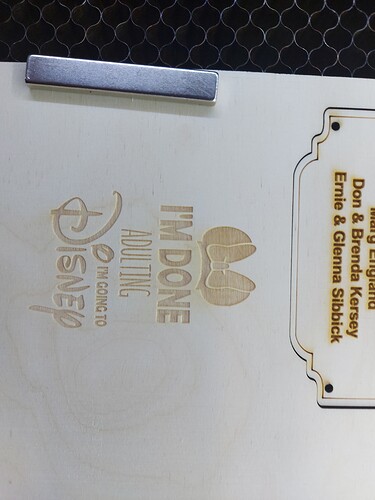

I’m going to apologize in advance for a long winded question. I have a 6090 machine , recently upgraded to the stepper motors to the hybrid style (encoder feedback ) . I haven’t used my machine alot since the upgrade. I recently decided to spark it up since Xmas season is on its way . I was having shifting issues , because I had replaced the motors my assumption was it was a mechanical issue , checked and rechecked pulleys, belt tension ect . Nothing . started playing with the line interval setting and suddenly things were working fine . First setting I was having problems with was 350mm/sec at .1 line interval . The setting that actually worked were 300mm/sec at .25 interval . With the line interval set higher I was able to increase my speed substantially almost 800mm/sec .

But what was also interesting was at 600mm/sec I completed the job in 1min 47 sec . but at 800mm/sec it was 2 min 29 sec my guess is the momentum caused lots of overtravel hench the increase in time. With all that being said , can anyone let me know why the line interval makes a difference in the shifting ?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.