Hi Group

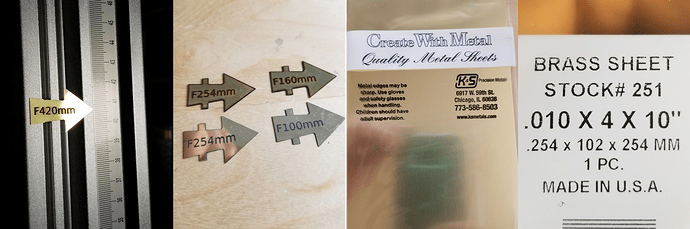

I am in the UK and I want to be able to deep 3d type engravings into metals like brass, bronze, alley, steel and stainless as a main job for the machine, but as well as other stuff like general laser etching and marking and hoping to potential play with and use colour marking too.

I would like to ask:

-

Laser power

if i can afford 100 watt or more is it a no brainer to get this power level?

I guess my concern is that i won’t be able to do more delicate stuff as perhaps the beam is to big or too hot etc…

Or will be perfectly ok to do my deep 3d type engravings with a lesser power machine say 60w or even 30w thus saving money -

what to look for when choosing a laser

I guess i need a Mopa fibre laser but what do i look for when choosing, i.e laser power, laser frequency, marking speed etc…

is there some base minimums i need to get and then if the numbers are higher then it is better? -

engraving depth

I have seen this listed on some laser specs, does this mean maximum depth full stop i.e it won’t go any deeper or does it mean it can cut 2mm depth in one pass? -

machines to go for:

I have looked at a couple of machines around the £6k mark i.e:

“cloudray” i think they have a JPT M7 machine i looked at so i assume it has a jpt laser source?

and

“wisleylaser” who offer a JPT mopa laser and they offer a jpt laser source or a Raycus laser source

are both these good companies to buy from or are there better ones to choose from? -

Expected service life

i have seen 100,000 hours listed is this a real figure will they run this long?

and does this depend on power and what i am doing or is it purely on the hours of use?

what happens at 100,00 hours is it new machine or a new laser source? -

fume extraction

do i need a proper self enclosed filter box that runs in the same room as the laser and exhaust air to the same room but the filters catch all the junk, and dangerous stuff, then i just change filters

and if so are these expensive to run?

Or can i just stick a 100mm pipe to out side and its ok?

do i need to consider anything else?

it’s a major purchase and decision so I hope I get some good feed back to help me make a decision to make a purchase.