Hi all,

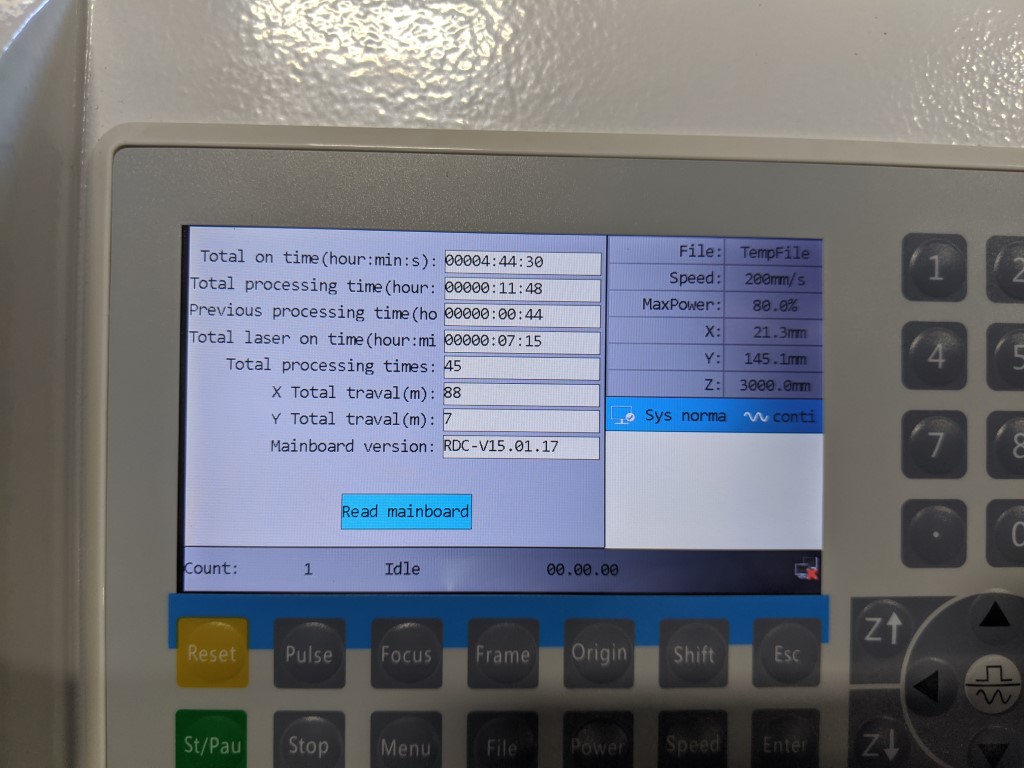

I just got my new DSP1060 machine (80-85, 90, 100, or 102.1 watts depending on where you read the specs) with a Ruida RDC6445G(EC) controller yesterday, and today I’ve got it up and running, mostly.

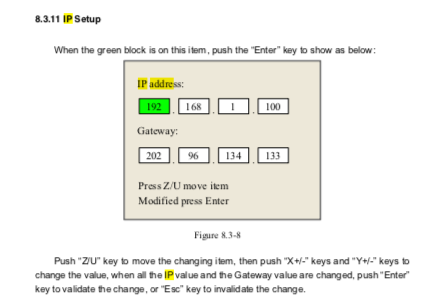

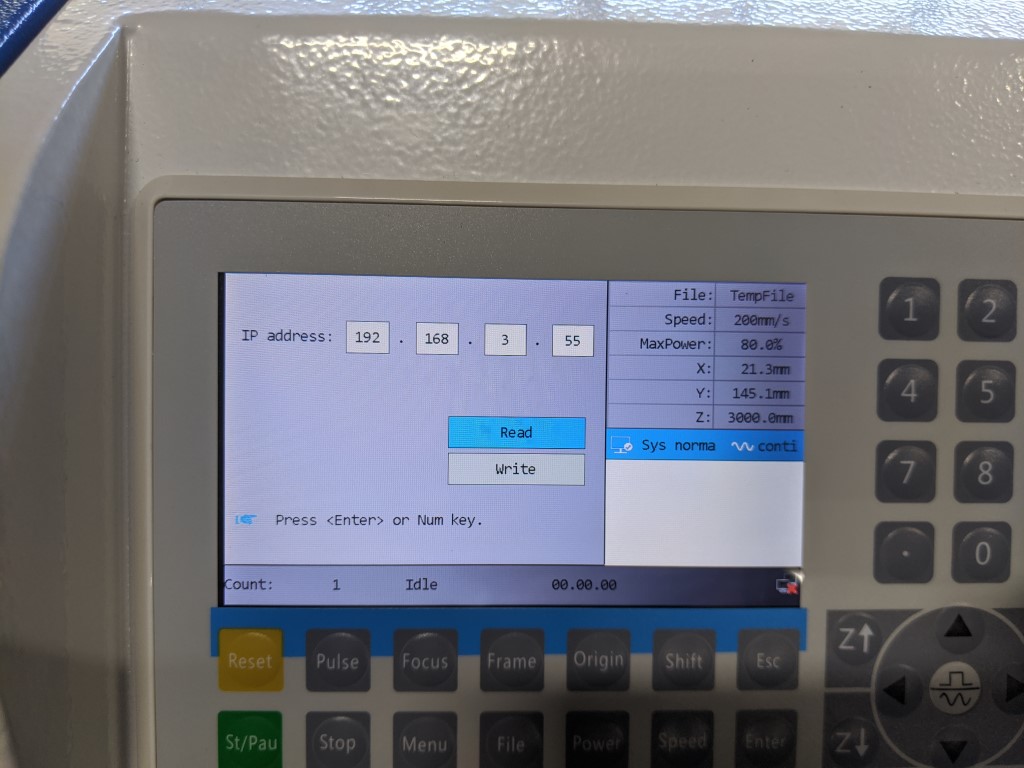

My most immediate question is about network setup. I’d prefer not to run it over USB. I’ve assigned an IP address and I can ping the machine, but LightBurn isn’t able to talk to it, and I confirmed with Wireshark that no traffic (aside from my ping replies) is coming back from the machine.

Has anyone successfully set this up? My first concern is that the controller doesn’t have a proper IP setup - no configurable netmask or gateway. (And as an embedded systems developer who makes networked devices, I find that inexcusable and totally baffling, but whatever.)

Does the machine perhaps communicate by UDP broadcast? My workstation is on a separate (wireless) subnet, and the laser is of course wired, so they’re not in the same broadcast domain.

Beyond the network setup, I have SO many questions but I’m not sure where to go because they’re certainly not LightBurn’s problem. There’s a lot more information on Chinese lasers out there than there used to be, but the signal to noise ratio is bad. Is there a definitive forum for these things? Somewhere I can find out about firmware versions, and maybe get a manual that actually matches what’s on the screen?

This is my first laser cutter, but I’m not a totally clueless noob. I’ve got an Ostling laser marking system that I’ve upgraded with a rotary axis and a homebrew powered Z axis, and I’ve got a decent amount of CNC experience.

I don’t even know who made the machine. I bought it from China CNC Zone. It came with absolutely no documentation or software, and I had to have them email me some links. The manual doesn’t match completely, and I can’t find one that does. I can’t figure out if there’s a newer firmware version available. I haven’t heard back from the supplier since that email with the links yesterday.

I’d like to have somewhere to ask questions like “WTF is up with this door safety interlock?”. It was set up to kill all AC power to the machine and attached accessories - by wiring the cheap plastic 1.5A rated switch inline with the main power input. So every time you’d open the lid, it’d drop the PC connection and everything you were working on and then reboot. I fixed that and got it wired in to the proper input, along with the water chiller alarm, and then had to hunt down the manufacturer’s password to get into the settings (it was RD8888, for the record).

A resource geared toward users building and upgrading machines, and not just trying to get their first cut parameters right or figure out the difference between vector and raster graphics would be great.

One planned upgrade that IS relevant to LightBurn is that I want to add an air assist solenoid. I believe that should be completely supported, right? As long as I set up the output and wire in a relay properly? I’ve already got a filter/dryer/regulator supplying air, not their tiny little pump. Anyone know what I should be setting the air pressure to?

Thanks!

Scott

ps - If LightBurn ever supported that Ostling, I would totally pay for another license, even at twice the price. It’s such a vastly different laser interface that I doubt it’s going to happen, though. It has no gantry, just mirror galvanometers steered by parallel digital signals coming from a dedicated PCI DSP board.