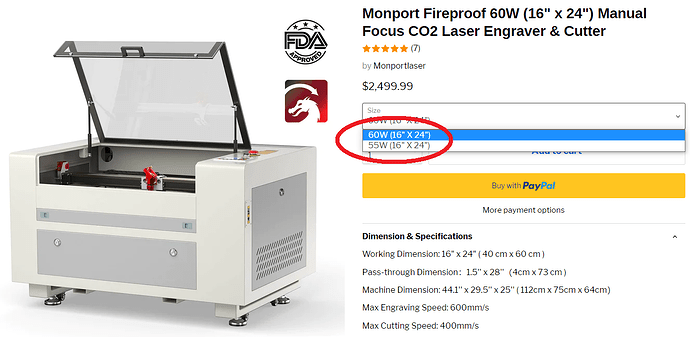

Does anyone have any thoughts, opinions, or advice about this Monport 60W Laser"

Pros (as I see them):

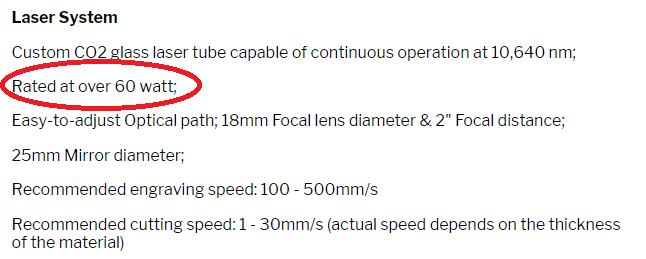

- 50% more power than my K40

- Twice the width and length of working surface

- Already Lightburn compatible

- Will still go easily into my upstairs converted bedroom and through the door

Cons:

- Not as powerful as an 80W or 100W

- Not the 24x36 that I’ve always dreamed of

- Not really a desktop size, but not quite a standalone height either

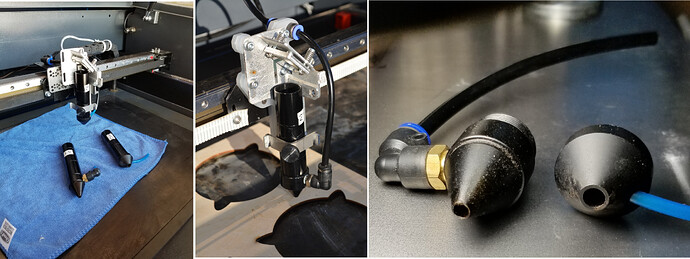

I’ve modded my K40 with upgraded exhaust, honeycomb bed, adjustable focus head unit, improved air assist, 3000 series chiller (yeah I know, not really a chiller, but at least fully self contained and wired into the safety cutoff), Milliamp meter, upgraded backlit thermometers, Lightburn compatible controller, and external Amber/Red safety light.

It has served me well as I learned about lasering in general, but I’d like to do some projects larger than 12x9 and yet still have a “Desktop” style device that will fit in this room. I’ve looked into similar Omtech lasers, but keep falling back to the overall looks, fit, and finish of the Monport, and they are similarly priced. Will likely purchase through Amazon, since the price is even a little better than the Monport 6% off that their direct website offers, and you cannot beat the Amazon return policy. Plus I’ll probably take advantage of the 12 months 0% option of my Amazon credit card.

I’ll be pulling the trigger soon (as soon as my taxes are paid for the year), but I thought I would ask the professionals and fellow hobbyists on the site for their thoughts first.

Thanx in advance

Jim in Hollister