I received a 24 watt laser from Wizmaker which seemed to be well constructed, not the flimsy 2020 rail construction suitable for lighter weight laser modules.

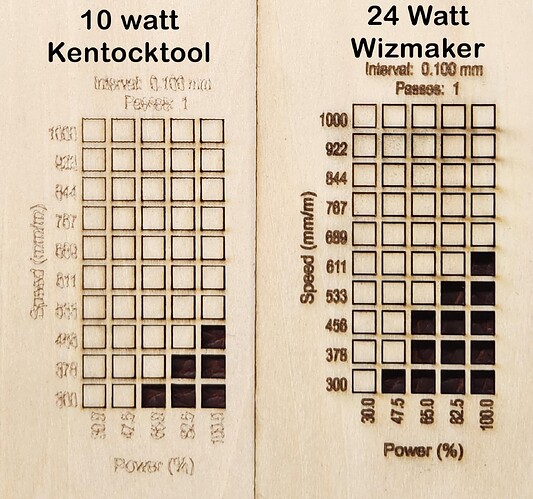

Once set up I ran an immediate materials test on 2.7mm bass ply and did the same with my current 10 watt. My 10 watt produced a clean cut at 456 mm/min while the 24 watt maxed out at the same settings at 611 mm/min, approximately 1.4 times faster or 14.5 watts worth of cutting power. When I queried support, they stated that that is normal and that their 36 watt laser only doubles the cutting thickness of black acrylic. Since we are talking apples and oranges, their response was meaningless. In prior evaluations of 20 watt lasers they seemed to double the cutting speeds for the same results but I had never done an accurate side by side on the same panel.

I am returning the laser this morning but would like to know if it’s me or the laser. Bottom line is that I need the cutting power of 24 watts for a forthcoming project and the Wizzbang isn’t going to cut it…pun intended!

To sum up I have assumed that doubling the power would allow doubling the cutting speed ± …is that correct?

Bob

(Note that I am in the process of replacing all the Vslot wheels in the Kentok laser to the labels are a bit squiggly…

UPDATE: Duh! If you look at the 24 watt materials test the 47.5% power cuts clean at 300 mm/min and the 100% power cuts clean at 611 mm/min. I ran a similar test on the 10 watt Kentoktool with 100 to 500 mm at 50% and 100% max and got exactly the same results. Double the power, double the speed. So it does look like Wizmaker is pedaling a 24watt machine that actually puts out 14.5 watts.

This is a well known Chinese expression, especially in Shenzhen: 呃得就呃. Translated it means, “If you can cheat, then cheat” I think the western equivalent expression in English is: “There’s a sucker born every minute”

Bob