Hello,

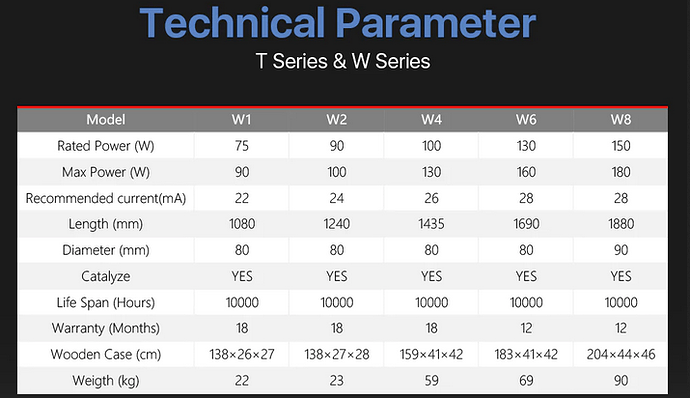

please, what shall be the power setting for this RECI W2 tube (90W nominal power)?

I mean in % (or maybe mA?). I’d like to set the minimum and maximum values in Machine Settings in Lightburn. With respect to working life of the tube itself.

Thanks to all for comments!

It’s usually wise to set the minimum parameter to the lowest value the tube will lase and you are comfortable with it’s operation at that low level.

Mine is set to 99% simply because my machines lps is set to 50% pwm for 50% being 50% of the tube recommended power. So I can’t possibly push it past it’s recommended current.

Make sense?

This is from the Cloud Ray link you posted…

![]()

Hi Jack,

thanks for your comments. To be honest, I am a bit lost in so many % signs used in your second sentence ![]()

Would be nice if you’d be so kind and put here a screenshot of your Machine Settings in LightBurn. Then I hope I’ll understand your meaning ![]()

Thanks in advance!

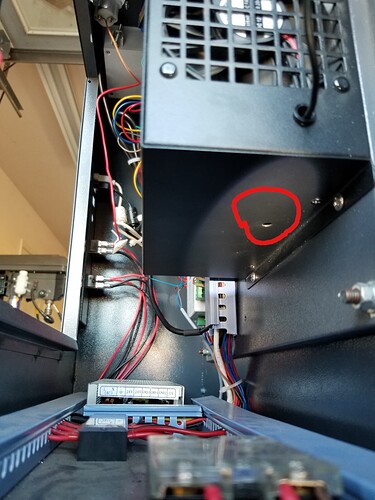

There is a setup procedure that I have found very functional but involves setting the lps via an internal pot. There is usually a hole in the lps that allows you to adjust it.

The procedure is to send a 50% pwm (power) or use the console to set it and manually pulse it in continuous mode.

If your 100% is 24mA, you set the pot for 12mA. This 50% control settings makes sure you don’t overdrive the tube during this setup procedure…

You have set the 50% pwm to cause 12mA to flow… In Lightburn a 50% power setting will result in a 12mA current flow… everything syncs up with the software…

The pot on mine requires a contortionist to adjust… this is from the back of the machine…

Any questions, sing out…

Good luck

![]()

Now I got it, thank you Jack!

So your meaning was regarding setting up the power supply /wrt desired power, fair enough and thank you for that. Just my initial meaning was what power range (in %) is recommended to use /wrt lifetime of glass tube. I mean, if I’ll feed glass tube with 100% power @ single pass for all of my jobs, then lifetime of glass tube will be much shorter then in case of e.g. 50% power @ two passes.

I’ve read some articles that some users never use 100% of power, but max. 60-70%, due to do not “destroy” the glass tube too quickly. And I was actually asking about those max. 60-70%, resp. what useful range is recommender for glass tubes (e.g. min. 20% and max. 70% ???), or even particularly for my RECI W2 ![]()

If you drove your new car at 10mph it would probably last quite a while compared to 70mph…

You are purchasing a big tube… it’s kind of a waste to run it down were a tube with 1/2 the power would work fine.

I think 100% all the time, is doable, by the specification, but I’m sure it will take a toll on the tube as would anything being run at it’s suggested 100% value.

I’m comfortable using 85 to 95% with no issues, and if I need 100% for those rare thick jobs.

Use it or not it’s gasses will break down over time…

It’s a consumable like any other… No point of a 90W tube if you can’t use it for 90W when needed…

Too many of these machines come with grade B tubes, yours from Cloud Ray is not a grade B tube… I’ve seen people buy 80W RECI tubes, marked 75W… this is a grade B tube, didn’t pass all the tests and was sold to a vendor for resale, as RECI couldn’t/wouldn’t sell it as an 80W tube… It’s a new tube, but a grade B tube.

If you limit your tube to 50%, the bottom 10 to 20% is usually lost, as tubes don’t usually fire below 10%.

I think one of the RECI specs might be the one I saw them mention a minimum of 12W for a 60W tube meaning they don’t recommend it’s use below 20%… That would limit your tube (for your 90W), to a range 20 to 50% … 18W to 45W…?

You can damage the gasses by running too little power also… if the tube isn’t resonating completely or properly, that can cause damage to the gases.

Use the tube with the power you need to do the job and when the tube is toast you have to change it out. Much like a saw blade… when it’s dull it’s dull…

I think you worry too much… this is a leading cause of frustration to users, keep the tube alive… It’s a drag to have to by a new one, but such is life.

Do you have a good chiller that will keep it around 68F (20C) while it’s running?

You could by a fiber, it has a 100,000 hour lifetime, supposedly… of course, no natural materials…

Good luck

![]()

Jack, thank you very much again for your comprehensive and valuable comments, highly appreciated!

Yeah, homehow I feel that sometimes I am too “careful”. Espec. when I am starting a new technical area, because up to now I was running LED laser for quite a long time, but its power became insufficient to me so I decided to build my own CO2 laser machine and that’s why I am “digging so deep” to achieve as much new info as possible ![]()

And yes, I am running CW-5200 chiller, set on 18°C (~ 64 F).

The only thing that changes with a different laser is the laser…

It’s frequency determines what it will effect…

Sounds like you’re doing fine… don’t worry so much about tube life, it’s a consumable.

I suspect you’ll have issues that exceed how well your tube is doing…

What are you expecting to cut with that kind of power…? just curious…

We’d all like to see your diy machine… don’t hesitate to post some photos …

Take care, have fun…

![]()

Hi Jack,

currently I am engraving and cutting plywood (3, 4 and 5 mm thick) and engraving some metal parts.

Regarding the new machine, it’s still “under construction”, but once it will be finalized (hopefully soon), for sure I’ll share some pictures ![]()

Take care!

Did know that machine would engrave metal … neat…

Glad you’re up… take care and have fun…

Be looking forward to your diy photos…

![]()

Sorry for confusion, better to say etching (or even marking) metal parts ![]()

Hi Jack,

just FYI, I started to share some short videos regarding my DIY CO2 laser on YT, playlist here

Feel free to see it ![]()

Just one more question, what minimum power (in %) would you recommend for RECI W2 tube please?

I mean minumum power % when tube creates stable beam.

You’ll have to figure it out yourself… all of these tubes lase at different power settings…

Use the pulse and see how low it will go… Unless needed, I keep mine above 10%, it will lase down to about 9.3% power…

I have dialed in the new replacement tube, so can’t comment on it yet…

Some reason you picked such a large head for the machine?

![]()

Sorry Jack, somehow I did not get the “large head” meaning ![]()

This is the head I have… it’s about 1/3 of the mass or less.

How do you adjust the Z direction of your head?

Just wondering…

![]()

Nice setup Jack ![]()

Well, as a starter I bought this laser head set. And when I want to adjust the laser head mirror in Z direction, I put washers under its mirror block.

These are steps… in between you can’t adjust unless you have an infinite number of different thickness washers… ![]()

Played that game… that’s why I got the head I have. I also bought it as a kit, sort of, from Russ Sadler in the UK…

Surprised you didn’t go that way when you built yours…

![]()

You know, I started without any experiences, this is my first CO2 burner. Let’s see the future ![]()

I’m sure you can handle it… just mentioned some of the things I got burnt with …

Keep us updated on your progress… people see you do it, then it help encourage others to follow along…

It is the best way to learn …

Good luck

![]()