Interested on what you are engraving…

It’s always been the more powerful machine is used in cutting and the least for engraving?

Few of these machines will do 1200mm/s, what kind are you running that will run this fast?

With easy numbers… 1000mm/s you cover 1mm in 1mS… these lps placard lists the response time of the lps is <=1mS… we are lucky if they respond that quick… it’s hard to measure, but we know from the industry what’s going on…

At 1000mm/s the best dpi possible, if everything is at spec, is 25.4 dpi or a single dot/mm and I doubt you could control it at 1000mm/s let alone 1200mm/s speed…

What I’m saying is you can’t really make it go faster, as you are probably there or past it already… The only thing faster is an RF excited co2 laser…

Your best bet to lower the overall time without affecting other things is to reduce the mass of the head and associated parts that have to move. This will allow an increase of acceleration values that will reduce the overscan.

When the Ruida scans, it will use the overscan area to decelerate the head, change it’s direction and get back up to speed outside the engraving area to allow it to engrave at the specified speed.

I think that’s what you mean by swing…?

I went from about 800g head assembly, not including the drag chain, to just at 100g. Mine will run 1650mm/s without a problem… however it’s only useful for academic purposes at those speeds…

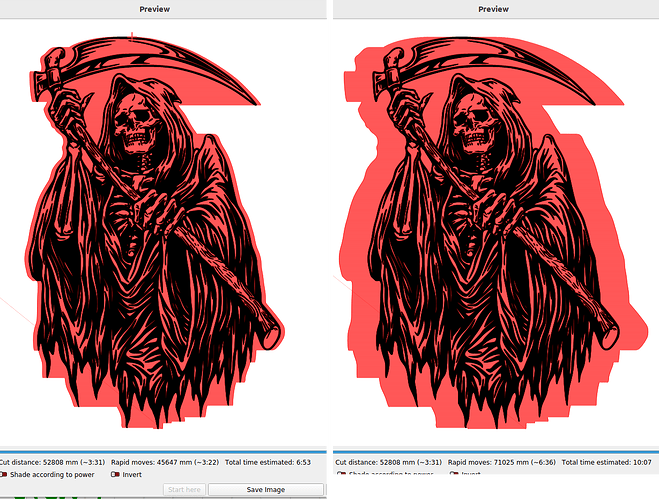

The payoff is in the overscan reduction… here is a 40000mm/s, left, compared to a 6000mm/s acceleration … the preview will allow you to see the overscan if you select show transversal moves.

Notice the time difference…

This is close to how the machine was received and how it looks recently… or a before and after…

The head is very simple, easy to align and has an adjustable along the Z axes…

Could be, if you can get around the physics, you could benefit the world

You didn’t mention what you were doing, which may change what we’d advise…

Hope this makes sense…

Good luck…