My neighbor has a small business where she cuts a lot of felt. Last year she cut thousands of pieces by hand. When I found out about it, I offered to use my MPCNC with a NEJE E40 (~10W) to do the work. It was a life saver for her, but I spent many hours cutting. I was able to cut through 4 layers of darker colored felt at 400-500 mm/min. She wants to invest in her own laser setup and it would be nice to get a more powerful diode laser. I don’t think the is ready for the cost and space of a large enough CO2 setup.

Does anyone have any recommendations for a diode laser system that can cut larger area (~40" x 30")? We would like to pull felt strait from the fabric bolt (~38" wide) onto the cutting area so we don’t have to cut the fabric into smaller sizes. I am looking at the NEJE Max 4 E80 (~20W) with the extension kit. Currently this is around $1200 with an extra honeycomb to cover the cutting area and an automatic air assist.

I could build her an MPCNC or Lowrider from V1 Engineering but it would come out to about the same price with the laser module and it feels a bit overkill as the MPCNC is build for the weight and torque of a router. I am worried the extra weight may limit the spead for engraving projects.

I am comfortable with DIY, but would also like this to be something that she can troubleshoot with a little guidance. Any thoughts are greatly appreciated.

One of the reasons I chose my Two Trees is the 450 x 450 cutting area.

The problem you’re about to run into is rigidity: typical diode laser machines are optimized for cheap with the thinnest possible rails that don’t bow too much over the unsupported length. The “extension kits” typically just lengthen the rails without increasing their cross-section, so they become even more flexy.

I built a (somewhat smaller) MPCNC a while ago and the round-section EMT tubes are utterly rigid, so IMO you’d be better off with a full-custom build, rather than buying a (spendy) upscaled commercial laser. It’s somewhat more rigid than absolutely necessary, but that’s easier to cope with than one that’s somewhat rickety to start with.

As a bonus, you’d use a stock GRBL controller (*) instead of the weird hackery inside the proprietary controllers, along with cheap & readily available stepper drivers.

I screwed mine to the top of a commercial workbench, but you’d likely put it atop a nice sanded / finished plywood sheet. Another bonus would be building in enough clearance for either a big honeycomb or a sheet-metal plate somewhat larger than the stock felt, perhaps with hold-down clips along the edges.

Basically, the application calls for a machine with specific features that you won’t get in a stock laser. A custom build will definitely be more initial hassle, but should Just Work™ thereafter.

Show us pictures as you build it! ![]()

(*) Avoid Marlin-based controllers, as they’re highly optimized for 3D printing and have weird quirks in CNC machines.

Jtech DiY Machine is about 40"x40" working. The motion system (controller, frame, motors, linear rails for X&Y, powered Z, etc) is about $1100. Add the laser of your choice. JTech makes those too.

I was “this close” to buying one but I don’t really have the need or space for such a large machine.

Sculpfun also makes a huge expansion kit (over 900mmx900mm if memory serves) for one of their machines that’s probably much cheaper. I haven’t looked. It’s a v-slot setup and no powered Z and made in China, so it better be.

OpenBuilds Acro system + their black box controller is also an option. Standard setup is similar design to the Sculpfun (v slot, etc) but it’s entirely roll+your-own, so make it how you want.

Thanks for the recommendation, Tom. 450 x 450 is a bit small for the bulk of the work we need to do. My laser was set up for 250 x 450 and we had to do a lot of precutting to get the felt to the right size for the bed. The Two Trees does look like a good option for a typical project.

Ed, Thanks for the input. I ended up using stainless tubing for my MPCNC to help with the rigidity needed for routing, then added a laser. With something like the NEJE Max 4, I wasn’t sure how much flex I would get on the extension rails.

As for controllers, I have been using a Big Tree Tech SKR Pro 1.2 running Marlin with my laser. It has worked ok, but I know there is some functionality and speed that is missing. MPCNC is shifting over to using FluidNC. Has anyone had experience with that?

Prior to posting, I had already ordered the NEJE, but there have been issues with shipping and delays with customer support because they are in Hong Kong and only available at certain times of the day. It got me rethinking my decision.

Some folks have been using that for lasering, with what seem like mixed results:

https://forum.lightburnsoftware.com/search?expanded=true&q=fluidnc

Good luck … 'nuff said.

Chris, Thanks for the recommendations. I was looking at the OpenBuilds Acro set up yesterday. That may be a viable option as it is very customizable and I can add the controller and laser that suits my needs.

The largest JTech machine I saw was 30" x 32" which is a little small for what I need and the price is close to double once I add a laser. It seems like JTech has always had positive reviews for their quality, but it doesn’t quite meet the needs.

The Sculpfun S30 Ultra-22W with the extension kit is right at the limit of the minimum size we want and is comparable in price and specs to the NEJE Max 4. I’ll take a closer look at the reviews. I do like the powered Z axis of the NEJE.

Re: Jtech…Sorry, I must have been thinking of the outside dimensions.

With the OpenBuilds, you could still do a Jtech laser head if you want to stay away from the Chinese stuff.

I do truly wish I could find space and budget for that machine with an OPT head. Maybe someday.

No worries at all. Thanks for the time and recommendations. Everyone’s insights are appreciated and helpful.

Hey Josh. What did you end up setting up for your friend? I am in a very similar situation trying to choose a machine build for my wife. She is also cutting fabrics and we have been looking at the Openbuilds Acro 2020 and a 20W or 30W laser module from one of Neje, Laser Tree or Sculpfun. The Jtech seems too expensive and too loud. Anyway, I would love to hear how your build went!

Hi Aris,

I ended up going with the NEJE Max 4 E80 Large-area Basic Kit. I also added a second 530x850 mm honeycomb and an auto air assist valve from NEJE. This set up gave us a cutting area of 750 mm (29.5") x 1030 mm (40.5"). This allows her to pull 72" fabric straight off the roll since it is folded in half (36"). I already had the NEJE E40 (claimed 11-12W optical output) on my own machine and had cut quite a bit of felt with it. I was usually cutting 4 layers at a time. When we got her NEJE E80 (claimed 24W optical output) up and running, I was pleasantly surprised that I was able to cut the same job up to 4 times faster.

The larger area made exhaust removal a bit more difficult, but I built a table roughly based off of this Vacuum honeycomb table for laser cutting - #10 by jjneeb - Everything Lasers - Avid CNC Community

I’ll have to get some pictures when I can get over there.

Those results sound really good. I bet she is really happy with that!

The combined honeycomb vacuum table also looks interesting. For a large work area I was thinking about vacuum zones that turn on based on the position of the laser using actuated blast gates. Maybe a bigger fan would be easier to do ![]()

I fell into a rabbit hole last night trying to find a future proof solution as the 45w laser modules (OPT $$$$) now weigh just over a kilo ![]() and I was concerned about the Acro 2020 frame flexing. So I started looking at the QueenBee ultimate build.

and I was concerned about the Acro 2020 frame flexing. So I started looking at the QueenBee ultimate build.

Sticking to the Neje 24w module on a Acro 2020 might be the way to go.

If you don’t mind, can I also ask what thickness and what fibre was the felt? (wool or synthetic) For the 4 layers you mentioned what power and speed did you run the 24w laser at?

It was really good you shared your experience here because a lot of the fabric cutting stories are about co2 and there isn’t a lot of diode laser cutting experience documented online.

Having different zones would be an interesting approach if you have a way to trigger them. When we are not using the whole area we have a thin vinyl sheet that we put over the honeycomb area not being used to make sure the air is only pulling through the fabric. I am using a 6" inline fan that exhausts outside through a cat door. It works well for cutting fabric, but doesn’t pull enough air when engraving the surface of an object. I do not have it in an enclosure. She hasn’t done much in the way of engraving up to this point. When I get some time I’ll work on a solution for that.

We are using 2 mm synthetic felt. The biggest factor in the speed is the color of the felt. The most recent job we did was orange felt cutting 4 layers at 2000 mm/min 60% power. Black and dark brown we can go faster. Light tan, yellow, and blue we have to slow it down and use more power. My NEJE E40 11W was 450 mm/min 95%. The NEJE E80 has a longer focal length than the E40 so it does a better job of cutting through thicker layers. I am sure a CO2 would slice through it a lot faster, but for the work area, the diode was much more affordable. I’ll try to get some pictures of the set up in the next day or two.

No idea how I would trigger the zones. Maybe, there is a way to get the head position from the controller or alternatively, one can use ultrasonic sensors on the X and Y axes to approximate the head position. It does not need to be accurate, +/- 10cm will do. At the moment I am trying to work out who to get the ACRO mechanics from in Europe. I am in France. It is not very clear who is reliable. Will work it out.

Now, the numbers you gave about the felt are so great! We will be cutting mostly organic materials (cotton fabrics, cotton canvas, linen, woolen felt, maybe some leather bits). But cutting 8mm of stuff and getting a good result is so exciting! I think we will be alright with the Neje module.

We need to set up the laser on an upstairs floor and the ACRO is so easy to move and rebuild from what I can gather. Also, by next year, more powerful modules will be more affordable. I would rather do that than try to setup a CO2 with all its bells and whistles. Also, from what I have read, you are supposed to run your CO2 at 60-70% max if you want the tube to last longer. That means a future 60W diode laser will be similar in performance to a 100W CO2.

PS. Sorry for the late reply. I never got a notification. Go figure.

In the meantime, I advise you to read the Lightburn documentation to learn terms and safety tips and to get used to the software. Lightburn without a laser

For information, there are 70w laser heads, but they have the disadvantage that the laser dot is larger.

As far as Openbuilds is concerned, they seem to have cut back on small resellers. I don’t know what their distribution chain is like at the moment.

To trigger the zones, perhaps a jig with a camera could work.

Hey Josh.

Ended up getting a NEJE with a large area kit like you guys did. I figured, if I was going to buy the module anyway, I should get one of the kits for an extra couple of hundred bucks to get started. It is arriving on Monday.

Once up and running, using Lightburn, testing fabric and we work out what we need, we will build a custom ACRO that can take full width fabric roll (150-170cm). I just don’t know how long we need to make it.

Thanks for your useful feedback!

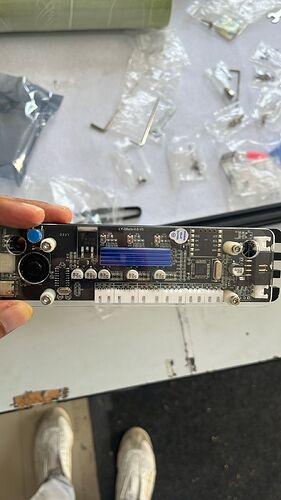

Hi All, the information on this thread has been very useful for me. I need to cut a lot of polyester felt on a daily basis (thickness varying from 1mm to 3-4mm). I was thinking of going in for an S30 10w laser but had a few questions - would be great if someone can help me with this: 1. what power and speed settings can i expect for doing this? 2. is it possible to cut multiple layers and if yes, what power and speed can expect for doing that? 3. I currently have a 15w output power laser attached to some custom build 1000 by 1000mm frame. Sending pictures of the board and laser module. Do you think i can replace the laser module with an s30 10w or even better s30 22w if i change the board as well without changing the cables?