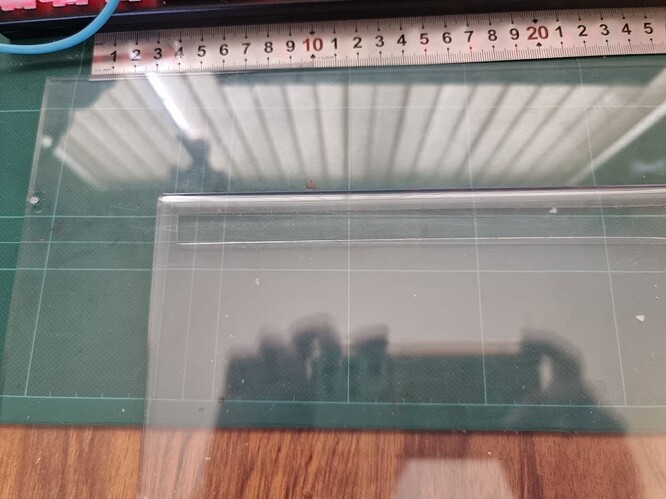

Scored some free acrylic displays, but need a method to release clear VHB tape holding them together. Any civilised ways to unstick parts ? I did pry one off but doing that for the lot is a bit much, plus it left marks on the surface.

I just did a quick Google and found a variety of ways including WD-40, IPA, and Lemon Oil (Limonene). However, before using any kind of solvent I’d research it’s compatibility with acrylic (you might also need to determine whether these are extruded or cast acrylic as I believe there are some differences in properties).

Out of interest I thought I’d see what ChatGPT had to say. Here’s it’s response:

Disassembling a clear acrylic display unit that is bonded with VHB (Very High Bond) tape can be a bit challenging. VHB tape is known for its strong adhesive properties, making it difficult to remove without proper techniques. Here’s a method you can try:

Gather the necessary tools: You will need a heat gun or hairdryer, a plastic or nylon pry tool, isopropyl alcohol, a soft cloth, and possibly a razor blade or utility knife.

Start with heat: Use the heat gun or hairdryer on a low setting to gently heat the bonded area of the acrylic. The heat will soften the adhesive, making it easier to separate.

Pry gently: Once the adhesive has been heated, start prying the edges of the acrylic unit using the plastic or nylon pry tool. Be careful not to apply excessive force or use metal tools, as they can scratch or damage the acrylic.

Apply more heat if necessary: If the adhesive seems resistant, apply more heat to the area you’re working on. Continue prying gradually, moving along the bonded sections.

Remove adhesive residue: After separating the acrylic pieces, there may be residual adhesive left on the surfaces. Apply isopropyl alcohol to a soft cloth and gently rub the adhesive residue to dissolve it. You can also use a razor blade or utility knife to scrape off any stubborn residue, but be cautious not to scratch the acrylic.

Remember, this process requires patience and care to avoid damaging the acrylic or injuring yourself. If you’re unsure or uncomfortable with the procedure, it’s recommended to seek assistance from a professional or someone experienced in working with acrylic and adhesives.

Remember that alcohol triggers instant stress-cracking in laser cut acrylic, as around edges of the green-Sharpie-colored regions:

Even the tiniest exposure produces cracks:

Given that you’re working with free material, you can afford to sacrifice one for tests.

A plastic razor scraper may help, but it definitely won’t peel the adhesive layer cleanly.

That’s correct, hence my comment on research! Personally I’ve found 2-Butoxyethanol, Dipropylene glycol monomethyl ether (DPM), Tripropylene glycol monomethyl ether (TPM), and Limonene to be quite safe on the acrylic I’ve used it on. However I’d always recommend doing your own tests. Unfortunately I believe that issues don’t always occur immediately and can take some time to reveal themselves.

Here’s a link to a chemical compatibility chart. It says IPA is fine but I’ve definitely seen recommendations to the contrary.

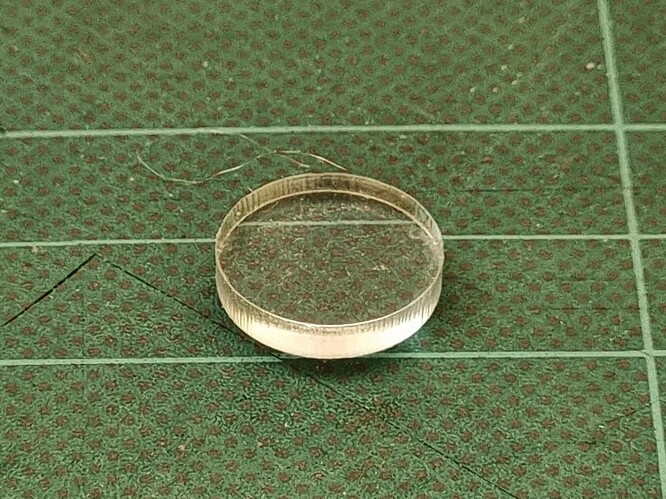

Update to the material: i dont think its acrylic, but its also not polycarbonate as it cuts rather nicely, no yellow/brown edge and smells different than acrylic or polycarbonate.

Tried IPA and it did absolutely nothing to both VHB or material. no stress fractures.

Cut out a 15mm circle just to test and thats the result.

Still need to figure out how to uncouple the sheets held by clear VHB…

Edit1: PET(G) ? what other clear plastics are able to be cut by co2 lasers ?

As an example, this photo show a pair of acrylic condiment cups… I soaked a part in one for < 5 minutes…

Left is normal, the right one had IPA … a day or two later it started cracking… It’s still usable, but… the cracks seem to multiply…

So IMHO, I’d say IPA is not fine… and AI, typical Internet answer … ![]()

I’ve keep the photos and still use the condiment cup, but it looks terrible… this comes up a lot…

Don’t know about the other chemicals mentioned…

Let us know if you have success and how you removed it…

Good luck

![]()

Don’t get me wrong, I’m not saying it’s fine, just that the data sheet says its compatibility is ‘Excellent’! Personally I wouldn’t chance using IPA on acrylic. I have a Formlabs Form 2 3D SLA printer which has acrylic printing ‘tanks’ (I’d call it a tray really). Formlabs tell you not to use IPA for cleaning them due to the cracking you illustrate.

Oh, and the ChatGPT answer was included just as a matter of interest (as stated). I’ve challenged ChatGPT with several answers it’s provided and on more than one occasion it has admitted it got it wrong and gave me a different answer!

Anyway, it would appear that it isn’t acrylic but possibly some other unidentified polymer.

You can google for a specific material to find out if you can lase it safely… That’s my suggestion…

This is a good starting point…

NEVER-CUT-THESE-MATERIALS.pdf.txt (115.7 KB)

It looks like acrylic and if it’s a store display or something similar it’s probably is acrylic.

The cut photo you posted shows an anomaly in the cut… This is from your photo, I marked the vertical lines indicating this issue.

In all likelihood, it’s a belt adjustment. I’d generally check that first, but a change in speed would determine if that’s the probable other cause. It should be a smooth surface without step type marks… this kind of anomaly can be very frustrating… and distracts from your end product.

I think it’s a great addition… I’ve signed up for it, but haven’t spent anytime using it… a number of people use it to describe an object and have it generate a script for something like Bender (3d drawing software on Linux) to create the drawing… it’s pretty fascinating…

Remember this…

So I take it as a machines suggestion, not fact… ![]()

![]()

I’ve used it for all sorts but you need to take the info it gives with a pinch of salt and in some cases verify what it tells you. To save me some time I asked it to write some Lazarus (Free Pascal) code to add to a Windows app I’d developed. The code worked first time so that saved me 1/2 an hour or so. I’ve also played with some of the AI art generators which is a lot of fun ![]()

It would be great if you did some art on the laser with it… you could post it in finished projects with an explanation of what did what… or how to duplicate a similar project using AI.

I’m sure it would be viewed by quite a few of us… ![]()

![]()

That’s what I was thinking while I was writing my post! I’ll let you know if I do anything worth showing off.

Not an anomaly (anymore), just crap construction of the motion of my machine. Then again i cut it fast and part is small, so direction change induces vibration, etc. I learned to live with it. Cant really be seen on ply, just plastics. meh. Overgrown k40, thats what it is (9060 sized one)…

The solution that I have used for years for removing go-pro mounts from a variety of surfaces including fabric-covered aircraft, is to take a long length of dental floss and wrap it several times around your two pointer fingers and then use it in a back and forth motion to ‘saw’ through the adhesive from different sides. Once you separate the halves of the pieces you can usually just use your fingers to ‘roll’ off the remaining adhesive and then wipe the remaining residue clean. I have never tried it on acrylic projects, but it always worked perfectly on the go-pro mounts.

I find that VHB sticks to itself better than anything else. If you can lift just a corner, then roll it onto itself and you can roll it off. Alternative is to find an extra piece and use that to lift up a corner. That gets trickier, but can be done.

Well, in my case the tape is located inbetween 2 sheets of material and unless i can pry one side off there is no rolling it up…

Have you tried a query to the manufacturer?

If anyone has the knowledge, it’s the people that made it.

![]()

No i haven’t. Reason being - they’re 3M - chemical is either going to eat the material or cost way (WAY!!!) more than low low price of free material i try to recycle ![]()

I’m just hoping that someone had to deal with similar situation and want to know how they dealt with it without scraping the ever living crap out of it.

Tried wd40 on one piece, made a mess and helped squat. Someone mentioned something about citrus something or other (oil?).

All they can tell you is NO… it isn’t going to cost you anything to ask them. If anyone knows they do and probably don’t sell the solvent…

I think you get more of an intelligent response from them.

I’ve dealt questions to these big companies, including 3M on some sealant, and they have always given me something, and it costs me nothing.

I always suggest the horses mouth, if possible.

![]()