Is there a straight-forward way to have the laser home to a position that is out of the way, somewhere toward the corner, in between cutting various layers? Reason being is the material needs to be flipped partway through the process. I have considered using absolute coordinates and always placing the raw material in the same place, but is there a method of accomplishing this that is more commonplace?

Not that I know of…

I don’t think that process is a good idea anyway. You don’t want people in there flipping material when the machine is actually in run mode… with a hot laser.

I have done this, but I loaded a seperate file for each side.

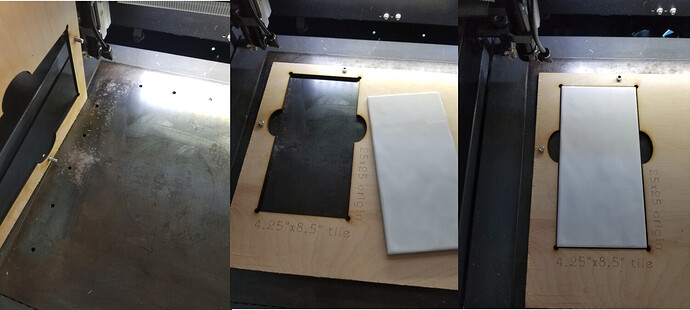

I have a steel bottom on my machine that fits into where the honeycomb used to be. I marked locating holes with the laser and drilled them with a drill press.

I made a jig to hold a part… I made one for a stereo cover that needed to be a bit larger than my work area. I had 4 file, one for each corner and the jig snugged that corner into the proper alignment…

This is one for a piece of porcelain tile…

Paint the backside…

Good luck

![]()

I put the backside on a different layer, and turn off Output in the Cuts window. When the first side is finished, it goes to the entered finish position.

I flip the part, then flip the outputs, and/or select other paths, and go at it from there. Maybe not efficient, but I do not get burned fingers.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.