I started another thread ( The dark arts of swapping lenses - LightBurn Hardware Compatibility / Ruida controllers - LightBurn Software Forum) about swapping out the lens on my OMTECH ZF2028-60E but have discovered that the lens tube wobbles a fair amount (in the X axis) to the extent that I had to wrap a .003 brass shim around the lens tube to take out the play. I’ve purchased an 18mm 2.5" FL lens to experiment with, but I’ll need to fool with that shim every time I want to change lenses. I’ve decided that I will need to replace the head assembly with something else, but what? I looked at the CloudRay heads, but the mount puts the head too far forward. The plate on my laser is 55mm wide and 95mm long. Everything else I’ve found is between 120mm to 130mm long. As Ed Nisley stated in the other thread, if I were to ask OMTECH for another head or lens tube, I would probably end up with the same thing. I would like to use the C series lens tube from Cloudray but it’s not going to fit my head, and the Cloudray head won’t fit my laser. Has anyone successfully swapped out the head on a 60W OMTECH laser? I’ve only had it for about a month and a half and I really didn’t want to get into a wholesale replacement of all the beam path parts.

If you really want to do this, I can hook you up with the Russ Sadler email and you can email him about it.

![]()

Thanks Jack, that would be great. What I should have said is, has anyone “besides Jack” swapped out the head. ![]()

Opinion: Don’t.

What you have works fine as a laser, even if it’s not perfectly aligned or configured. Play that ball as it lays, without replacing anything unless it stops working.

The question comes down to this: do you want to use the laser or tinker with the laser?

For the former, epoxy the shim in place and start making stuff. Lenses & mirrors are consumables, so put a set on the shelf against future need and move on. You can then make gradual, one-thing-at-a-time improvements as you understand why that particular thing would be a benefit and can measure the change to verify it’s working the way you expected.

For the latter, embrace the wholesale parts replacement firestorm and tinker away. Folks spend far more on their hobbies than you ever will, so have fun.

Onward … ![]()

I’m glad to hear yours has had no modifications and you just use it… ![]()

Mine was a real pain in the a** until I replaced those parts… not that it wouldn’t work but maintenance was so horrific I dreaded thinking about it, let alone actually doing it… I don’t think about it anymore… easy setup, alignment even from ground zero…

Of course, I like to tinker. I got it to learn how it works… take it apart and put it back together a bunch of times, you kind of get the hang of it.

![]()

Don’t we all? ![]()

Right now, I’m in the middle of shifting all the mirror mounts around to re-center them and keep the beam centered. None of that was true with the as-delivered hardware, but I’ve been using the laser that way for a year because it was Good Enough for what I was doing.

Like fiddling with the tube position on those rickety holders: what were they thinking?

Now it’s time to improve that, but AFAICT the fancy Cloudray tube holders might fit, but would require drilling & tapping some new holes. So I just made some simple pads to support the tube clamps that work with what was available in there:

Plenty of mods along the way, but nothing that keeps the laser out of action for more than a day at a time. Of course, I count making the new parts as “staying in action”, which may be cheating.

![]()

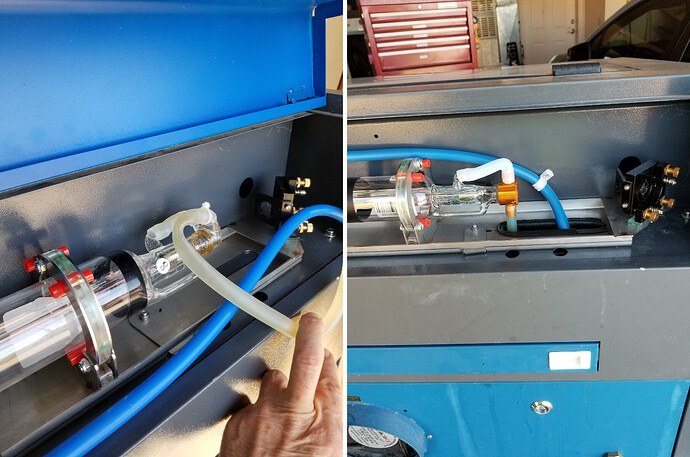

I changed mine out with a tube holder.

The frame holds the tube mounts and the mirror has ears to hold it at a 45 deg angle… On the left is the original tube and on the right is the replacement from Cloud Ray…

Notice the tube mounts…

For those interested, here is a video from Sadler that explains most of his items…

![]()

Thank you both for your input. In my attempt to get the beam to land on the sweet spot of mirror 3 I gave mirror 2 a slight tweak (I marked their original positions and I’m glad I did). While I got the beam closer to the center of M3, I managed to push the beam a bit into the nozzle when the head was anywhere to the right of the centerline of the bed. I was getting an engraved line to the left of any cut in the right half of the bed. I put the knobs back where they started at, and the problem went away. Big lesson learned. To answer your question Ed, I want to use my laser (I have a very small client base that I do cutting boards for) and right now it’s working well. I thought I could get that last little bit of perfect alignment, but I don’t understand the process well enough right now to get there. A future me will, present me is going to hold what I’ve got. The temptation to tweak is strong, I’ve done a lot of it with my diode laser and 3D printers. I’ll leave the subject of alignment for another day.

If it works don’t mess with it… good adage…

Do any kind of upgrade when you have plenty of time as it’s not like picking up spark plugs that fit anything…

Have fun…

![]()

I lust after those, but AFAICT the tube compartment in my otherwise ordinary red-n-black cabinet is juuuuust slightly narrower than spec, so the stock mount & cradles & suchlike don’t quite fit. Maybe the metal bender was having a bad day or the welder was offset by a smidgeon or whatever.

However, the simple fact that OMTech had to hand drill & tap half a dozen holes for the tube & mirror mounts definitely says something is wrong in there.

When it comes down to a few millimeters one way or the other, I know better than to trust the product descriptions.

Moral of the story: don’t order anything until you understand where it will go, what it will do, and why it’s better than what you have now.