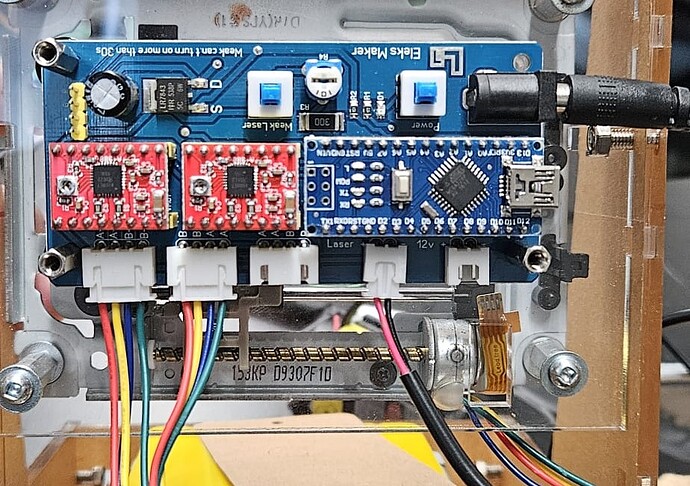

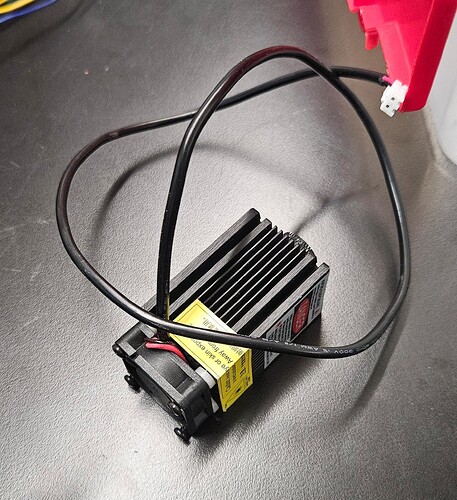

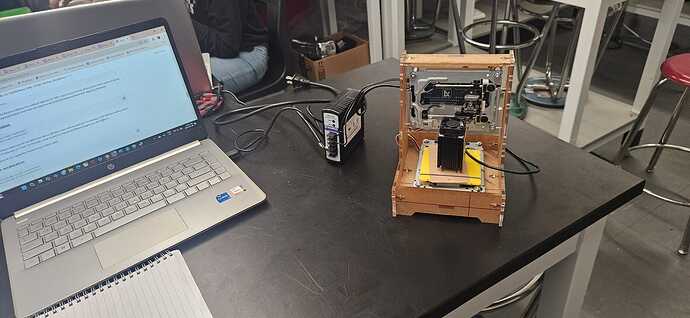

I have a 2 axis laser engraver set up. The laser module is 300 MW. The controller is Arduino nano. I tried connecting the arduino with benbox software and I am stuck. Please help me. This is for my school project. I was already given this set up as it is. So I don’t know much specifications. I have attached the pictures here. Kindly help me to understand this.

That’s a cute gadget. Peel the protective paper off the acrylic and it will become a little jewel! ![]()

This forum is largely about LightBurn control software, so it’s unlikely you’ll get much help setting up a CNC-ish machine running Benbox firmware & software, simply because few people know much about those.

I doubt the Benbox firmware is compatible with LightBurn, but that’s relevant only after you get the machine set up and running with its basic software.

Also, remember it’s your school project, not ours, so we’ll expect you to hold up your end of the assignment.

With that in mind, a casual web search brings up a bunch of useful pointers:

The startup checklist in this review seems reasonably complete:

If that doesn’t get it running, let us know …

I haven’t seen that Rhino box before. What does it do? Does it need to be plugged in?

That arduino board most likely has a CH340 chip on the back of it. If the board can be unplugged from it’s socket you can confirm.

The CH340 chip is a common communication chip. You may need to install a driver in your laptop to talk to it.

Most likely it’s the power supply:

Some observations:

The lower two terminals on that power supply expose 120 VAC. There should be a plastic cover for that terminal block, but if it’s been lost, make a cover from chipboard / thin cardboard and tape it securely in place so that nothing (and nobody!) can touch those terminals.

The supply is intended for a three-wire 120 VAC line cord, but that’s a two-wire widowmaker. The missing third wire is the earth safety ground that will protect you from an internal power supply failure. Find a proper line cord and wire it correctly.

If that is the supply shown in the link, its 1.25 A output current will be barely adequate to run the controller + stepper motors and may not be able to power the laser head. While you’re getting the machine set up, do not connect the laser to the power supply. After you get the machine moving correctly, then connect & check out the laser: if the machine stops behaving correctly, the power supply is inadequate.

Although 300 mW is a relatively low power laser, it’s entirely adequate to destroy your retinas. You have already been issued all the eyes you’ll ever get, so find a box to completely cover the machine when the laser is active and use it every time.

Protip: At least one of your buddies is prone to fooling around and doing stupid things, so find / make up a reason to not fire the laser in their presence.

Trust me: this advice comes from Future You.

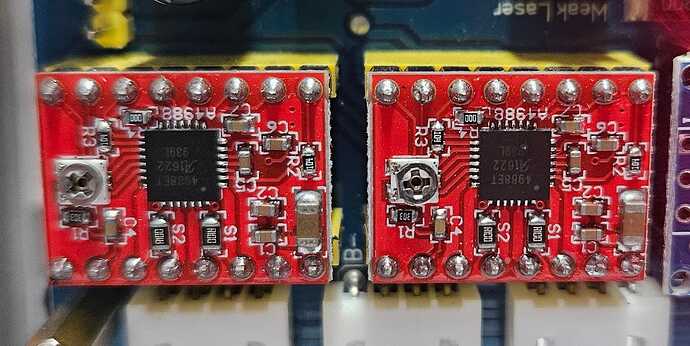

Thank you so much. I got my laser working. But its not able to engrave anything. The laser module is just moving. And its only moving in the X-axis and not in the Y- axis. I am not able to figure out why. I tried rearranging the connection. But thats not it. Any inputs on this will be helpful.

That’s a good debugging test. If the X axis continued to work and the Y axis was still dead with their motor leads swapped, then the problem is probably in the Y axis stepper driver.

It looks like finding the cause will require electronics test equipment and a climb up that learning curve before you get to anything involving LightBurn and lasering. Perhaps someone else around here can help guide you through more tests.

This is good advice for any laser user. Thank you @ednisley !

There ‘should’ be a blue dot. High Quality safety goggles may not let you see the dot.

A readily overlooked challenge when starting out is attempting to engrave reflective material. White cartridge paper (typically for photocopiers and printers) reflects blue light very well which makes this type of paper a challenge to engrave with a blue laser. When the paper begins to singe and darken, it becomes very easy to engrave. This property makes it hard to control.

Consider a using a sheet of paper from a yellow Legal pad for testing a blue laser. It will respond favorably to a low power laser.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.