I didn’t know you can restart a job from anywhere you want using the preview window. This would be handy in case of a power loss or disconnect when running a job. Watch the video. Using the Preview Window to restart a job is at the end of the video

Good luck, it’s an approximate solution, if you end up at the exact spot I’ll buy you a beer, especially with a photo it’s almost impossible, you’ll inevitably have places where the laser will have passed twice creating a line or several, darker because burned twice

Im open if you have a better solution. The issue came up with a friend of mine who had a job that was going to take 17 hours to complete and didn’t want to stay up all light or leave his machine running unattended. Pausing the job was not an option as that would leave the stepper motors locked, And that’s not a good thing

I’m not claiming this is the best or the correct solution, but here’s another alternative method to resume a halted job.

Seems like the only way this would work to recover a halted job is if you knew it would be halted before it happened. The intent of this procedure is to layer jobs to big to fit on a given work space.

in fact it would be necessary for the cards to send their position in real time, that lb has a function which compares them with the position sent by lb, and in the event of a power cut it would be easier to return to a precise location, unfortunately few machines have this function

We have found many uses and solid feedback from the community that using this method has been very constructive in their job recovery. Glad you found it! ![]()

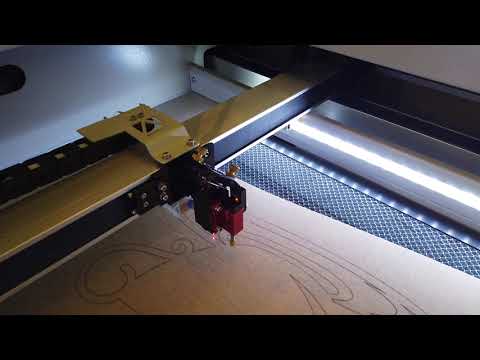

unfortunately it doesn’t really work for photography. But works well on vectors

That’s why I considered this as another possibility: planning to stop and restart due to the 17-hour program.

Just some food for thought, that’s all."

![]()

Somewhere there is a posting or video that says restart with Scan Angle 180 degrees. Then stop it when you get to the original burn.

Hey @MikeyH, I have timestamped / marked the video at the point where @daniellb provides this exact option. Thanks for the suggestion. ![]()

More than one way!

D’accord mais rien de bien précis,sur un point laser de 0.08 mm,c’est impossibe de s’arreter (methode 180°) ou de repartir a l’endroit exact du projet,il y aura obligatoirement une ligne ou un espace gravé deux fois donc plus sombre!

Pour un rendu profesionet c’est pas viable,temps et materiaux gaché,article invendable.

ol faudrait que lb stock les derniéres coordonnés point graver ou coupé,les carte mks ne communicant pas les coordonnés.

Ensuite une fonction permetant de repartit exactement de cette position.

Okay but nothing very precise, on a laser point of 0.08 mm, it is impossible to stop (180 ° method) or to start again at the exact location of the project, there will necessarily be a line or a space engraved twice therefore darker!

For a professional rendering it is not viable, time and materials wasted, unsaleable article.

We would have to have lb stock the last coordinates of the point engraved or cut, the mks cards do not communicate the coordinates.

Then a function allowing to start again exactly from this position.

If it is that critical, put the laser and computer on a UPS (Uninterruptable Power Source) and hire someone to watch it.

Live with the shortcomings of a low cost table-top laser or pay $15,000 to get a laser that can restart anywhere. You have lots of options.

I did not mean to upset you, and if I did, I apologize.

I was just pointing out the options we all have to face with these machines. Unfortunately, Lightburn makes these machines look better than they really are. It allows us to take hobby lasers and do real art and production work with them. Unfortunately again, it cannot cure every problem we encounter. Fortunately, it does a remarkable job of overcoming a lot of the shortcomings.

Huge thank you to @baricl1317 for drawing folk’s attention to this Recovery Feature. Additionally, we always enjoy seeing others jump in with their choices for recovery of a job. As we often say around here, “More than one way!” Greatly appreciated! ![]()

I am closing this thread to curtail contributions that bring little and are off-topic.