I’m coming from Easel where my tool head always returned to start position when the job was complete. I created a test project that cut 2 circles using a profile cut. When the job completed the tool head retracted but did not return to the starting position. Is there a way to have the tool head return to the starting position. I’m sure there is a setting that I am missing somewhere.

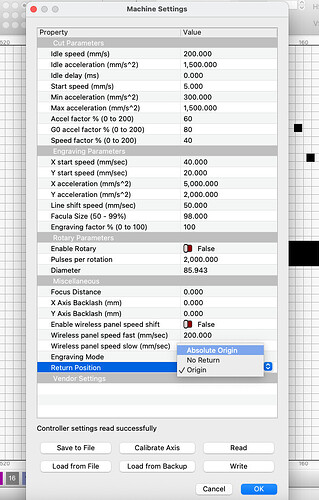

You don’t specify what kind of machine you’re working with. On a Ruida controller there is a setting in machine settings labeled return position.

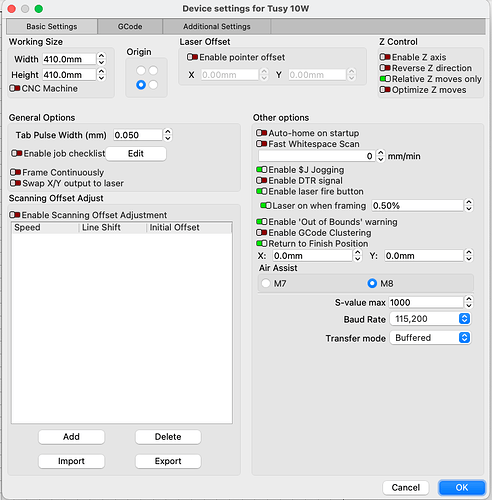

On a diode laser (GRBL) there is a setting in Device Settings labeled Return to Finish Position. You can enable and set that to whatever position you desire.

Sorry its an XCarve CNC. My Laser works fine with lightburn, but my issue is with MillMage.

Soory, I didn’t pay attention to the category. It’s a bit confusing having both softwares on the same forum.

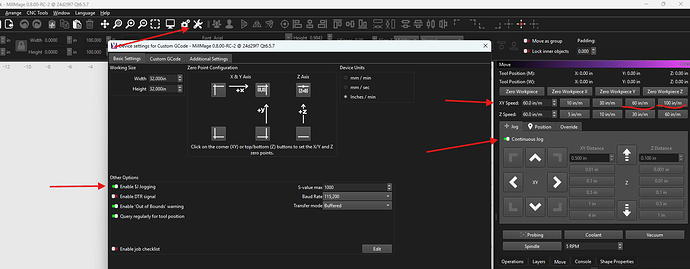

So it looks like you need to add custom Gcode in the “Device Settings- Custom Gcode tab at the End of Job section.” I thought it may be a setting in the configuration. Could be a good option to ad somewhere since this is still in early development.

An alternative method to consider:

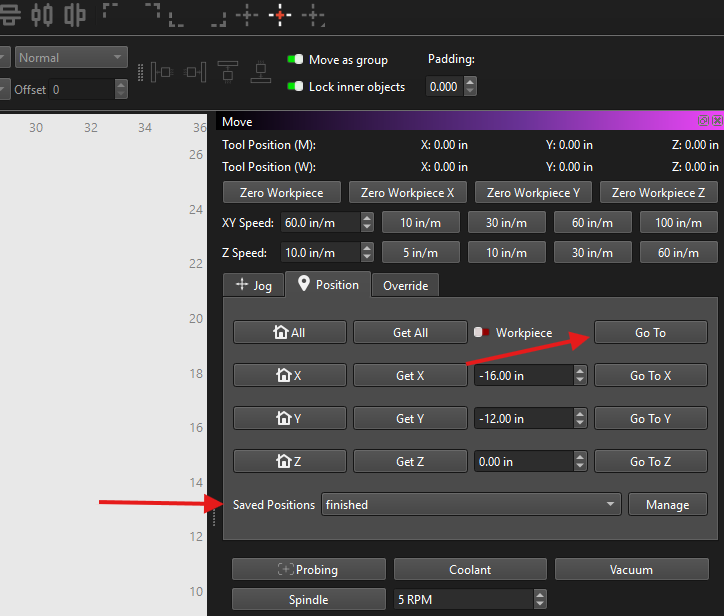

I added a finished position in the move window, and I really like how it retracts the Z axis while holding the X and Y coordinates steady when the program completes. This allows me to check for any obstructions before moving it to the finish position I set.

Exactly - every machine is going to be different, as will each user, so MillMage is built with the expectation and ability to customize the GCode output. Typically, this is done with custom postprocessing settings in other softwares, called ‘posts’, but MillMage instead does this with Custom GCode in the Device Settings. Potato Patahtah

Thanks, I’ll definitely take a look at that to see if it will work for me. It looks like the flexibility of this program is going to make it a great tool for CNC users.

could also be handy way to set up a parking position . i like to send mine to back of table so i can remove full sheets , vac table put on new sheet than bring it back to front , this option its 2 clicks once you save the position , have you worked a way to change travel speed for y axis, or could just sset up macros

It’s all GCode, you can see in the Console what is being sent, and use macros if needed or the overrides here: Move Window - MillMage Documentation

We have docs on how to use the saved positions here: Move Window - MillMage Documentation

One thing I discovered for jogging the X and Y axes is using the ‘Continuous Jog’ feature.

You’ll need to enable it in the device settings first. After that, I usually stick with speed settings of 60 or 100, which have worked well for me.

However, you can enter any speed you like—I’m just not sure what the maximum limit is.

had a play with setting macros yesterday , but brought up error codes and wouldn’t move cnc, going to have another look today to make sure ive entered them correctly , prob user error,

in macro does MM, need a G code 1st /

or can it just be eg: x500, y2400,

in macro does MM, need a G code 1st /

or can it just be eg: x500, y2400,

It needs to be G-code/commands supported by your controller (See Macros Window - MillMage Documentation). In the example it is using the ‘$’ commands supported by grbl.

Some controllers also require a decimal.

X0. Y0.

For example.