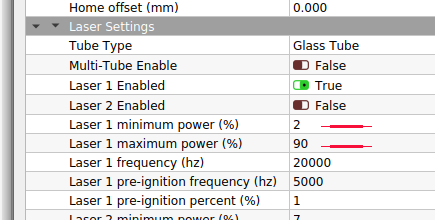

Many months ago I ran a power scale array test for cutting mounted photos on photo mount board. For my test I used minimum of 10% and maximum of 75% settings. I used 10% as minimum, because at the time it was my understanding that my laser wouldn’t fire below 10%, and I thought that might ruin the results of the power scale test. The best setting for cutting was at 45% indicated on the power scale (10/75 min/max).

Now, months later I’m ready to cut and am curious about settings in my “real” project. Obviously, I could set these layers to a min/max of 10%/75% and set the power scale to 45% and this would be exactly as tested in my power scale test.

However, that seems like I am having to set more values than I would normally. Given the math specified in previous power scale threads, the 45% setting at 10%/75% would equate to 39.3%. So, the question is whether or not that really holds true? Can I simply set my current project layer to 39.3% (40%?) without any power scale adjustments, and assume I’ll get the same cut I got on my power scale test?

Thanks in advance,

Ray