I have an Omtech laser and rotary I installed. Sometimes when I start a job the rotary spins very fast then starts lasering. Then when the laser finishes it spins very fast back to the origin.

First question: How do I make sure the laser starts from the point I align it to.

Next question: how do I slow the rotation down when it moves before and after lasering?

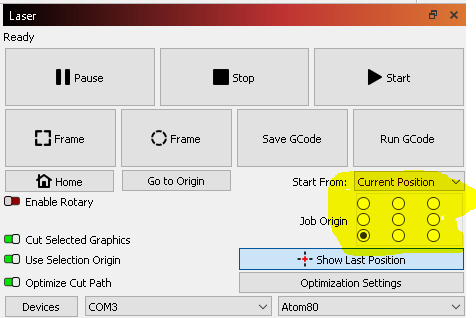

- Try “current position” (better for roller) and select job origin

.

.

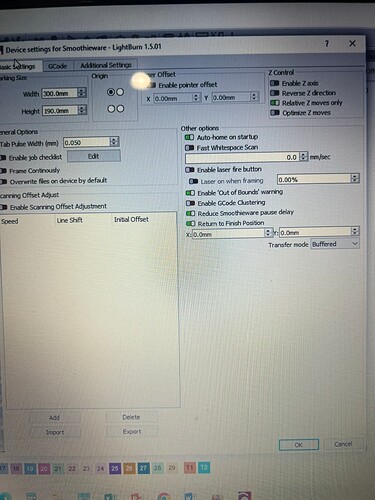

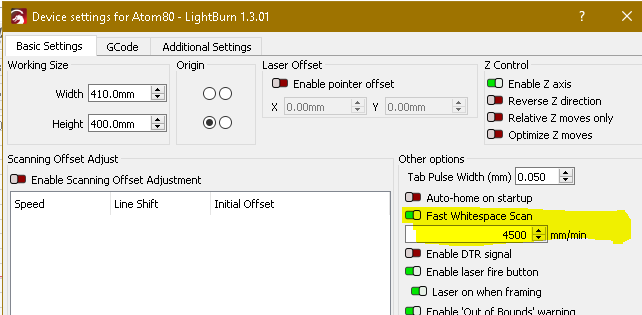

2.disable “fast whitespace scan” or lower scan speed

DONT FORGET TO REVERT TO YOUR NORMAL SETTINGS FOR FLAT JOBS.

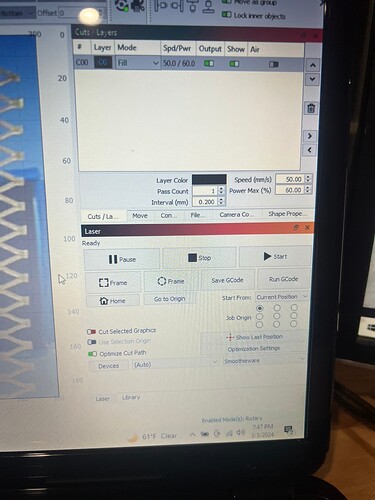

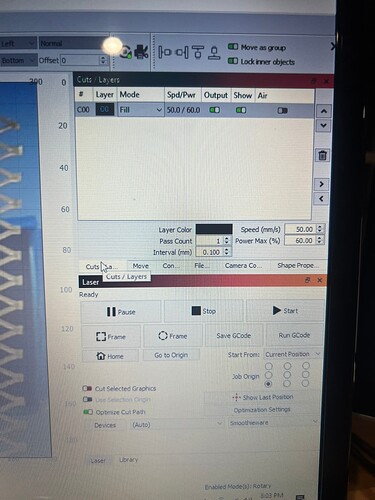

I have all those settings configured but it still spins very fast when it jumps to the next position to laser and sometime at the beginning and end. Below are all my settings.

Were you able to use the roller before and this has only just happened or did it never work?

No it was never used before. Im a beginner. Everything is fine with actual engraving. It is just the movements before and after engraving. Then sometimes while engraving, the movement between letters, for example, is too fast and spins the object on the rotary.

I’ve only just noticed that you have a CO2, I don’t know if there’s a specific setting on the k40 controller, or maybe the following links will help:

https://k40lasercutter.com/recommended-k40-laser-cutter-settings/

https://www.youtube.com/watch?v=YQXQx7FqeSI

https://mellowpine.com/laser/k40-laser-cutt

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.