I have an EleksMaker rotary, connected it to the Y axis of the Ortur LaserMaster and calibrated $101 to 95.700 to set the steps/mm so that it moves 40mm on the side of a soda can. To do this I put tape on the can and marked off 40mm using a ruler following the curve of the can. Then in the Move Tab I set 2 saved positions, each 40mm in the Y axis away from each other. Called one “rotary origin” and the other “rotary cal 40”.

I can go back and forth between the marks just fine using the saved position buttons and a 40x40mm box will frame to 40x40mm but when I try to cut/mark the 40mm x 40mm box it doesn’t give me 40x40. I get 40mm in the X direction but 43mm in the Y.

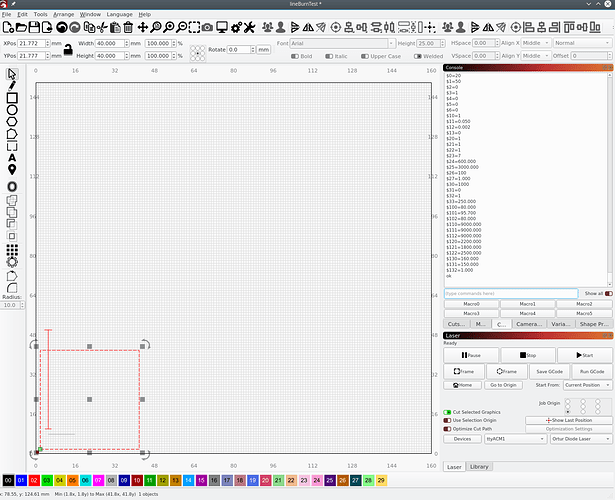

The box is set in Lightburn to 40mm x 40mm in the Height and Width fields and when I use the visible diode framing tool it aligns with the 40mm spaced marks I put on the can.

I used $# to see I had originally a 2mm offset so I cleared those with this command:

G10 L2 P1 X0 Y0

verified it and have already depowered and restarted the device to be sure it wasn’t picking up old values.

I aligned the led enabled frame with the 2 black marks(40mm apart) but in the pic you can see the white etched line is not lined up and it’s 43mm in the Y and 40mm in the X(along the can length). I have since solved the offset issue by using the “Use Selected Origin” option as I missed that and thought Start From:“Current Position” was supposed to do that. The box is still 40x43mm though.