Thanks very much, @LazerX. I’ll check out the rotary. I’m definitely in the market for a chiller - things are ok right now here in NC, USA in winter, my garage is about 50 F and I installed a temperature probe at the water return outlet and the water temp does get a little higher, but within accepted limits. But by summer, I’m afraid ambient temperature gets to be around 90 - 100F on a good day, so I chiller is definitely in my future as the season progresses.

I did get an in-line fan similar to the one you have, and it worked well - nice and quiet. I decided it didn’t pull quite enough, though, so I got a Y ductwork adapter and got a second in-line and run them in parallel which dramatically improved the venting.

I added an ammeter the first day I got it so I don’t overdrive the tube. I have the 80W also. And got the mirrors aligned well, and replaced the honeycomb with a sheet of flat steel and just raise my work up off the steel with magnetic spacers to give a gap. The steel plate makes cleaning the surface with acetone a breeze.

I had a little trouble at first getting through 1/4" plywood at what I thought were reasonable settings, careful with watching the ammeter and current draw. I was able to get through by slowing the speed way down, but still thought it should cut better.

Now it cuts great and much faster speed, but I changed two things and I’m not 100% sure which made the most improvement. First I upgraded the supplied anemic air assist with a 3500 GPH air pump which is a great airflow improvement. And while cleaning the mirrors and lense, I noticed the lens was in upside down, so I put that right-side-up. So perhaps a combination of the greater air assist to blow away char and allow the beam less obstruction while cutting, plus a better focal point, and clean lenses, it now makes quick work of 1/4" ply and I’m ready to try some thicker material to test the limit of what I can expect.

I really do like the machine a lot - I don’t mind doing a few upgrades and improvements, and in fact I enjoy it. So it’s been great fun and expanded my tool kit in making parts - especially replicating parts vastly.

Thanks again for the offer of hints and tips - I’m sure I’ll take you up on it.

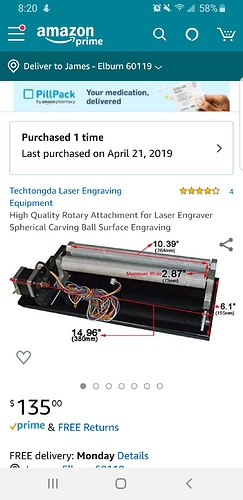

I haven’t seen anything off the shelf for doing spheres, but would be an interesting control project.

I haven’t seen anything off the shelf for doing spheres, but would be an interesting control project.