LightBurn 1.2.01

I have a DIY laser with an Arduino Uno and GRBL with a rotary chuck on the Z axis. In LB rotary setup it asks for mm per rotation. Is this correct? It seems to me that steps per rotation would make it much easier to calculate the circumference with a know dia. as mm per rotation will change with the change in dia. I am struggling with the idea of having to recalibrate the rotary every time a work piece of a different dia. is used. Can someone please clarify that I am interpreting these settings correctly.

I think if you bring up the rotary gui, you can enter the diameter of the object and Lightburn will calculate the ‘surface speed’…

You should not have to re-calibrate when you change diameters, only enter the diameter value in the rotary gui, Lightburn should handle it from there.

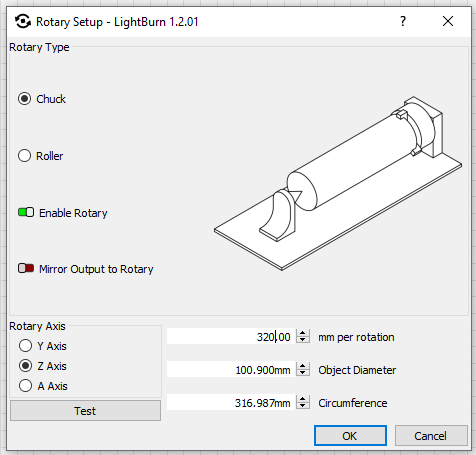

mine shows step/rotation, it’s a Ruida, not grbl.

“For GCode devices with a dedicated rotary axis, this number should just be “360 degrees”. If not using a dedicated rotary axis, you’ll have to use trial and error to dial in the correct travel distance using the Test button” from the docs site…

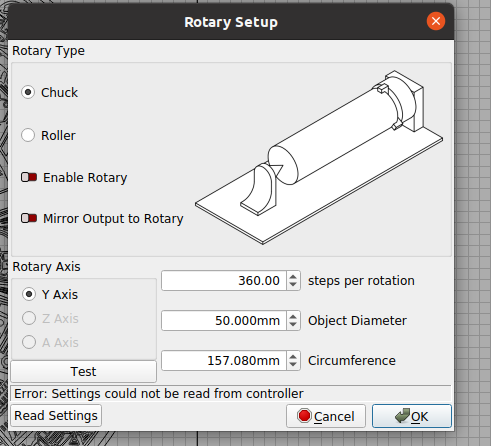

![]()

This is Setup gui I get. Steps per rotation would make more sense than mm/rotation. As the dia. of an object increases a calculation based on steps could automatically compensate for the change and calculate mm/step based on that. For example my machine requires 2400 steps per rotation. If an object has a dia. of 100mm the circumference would be 314.159mm. 2400steps / 314.159 = 7.63944steps per mm.

If the object has a dia. of 150mm then the circumference would be 471.239mm and the steps per would change to 5.09295. It would be easy for the software to change the Z axis mm/step in GRBL settings to the required number.

If the step/rotation is the dsp, and the mm thing is grbl - both do the same thing. Like metric and imperial… they both are just units.

Grbl is just setting it up with a different unit.

If your Ruida is setup correctly you should not need to do any computing for circumference, nor change the steps/rotation. The gui for Lightburn has a place to put the diameter, that should be all you need…

Lightburn knows how to rotate the chuck 1 turn. It uses that and the diameter you enter to compute the ‘surface speed’ which is all you need…

Set it up as per the Lightburn advice and test it as they recommend. You should never have to change the step/rotation on a Ruida or the mm thing in grbl, once correct. A chuck does not change in the number of steps (or mm) to make 1 rotation.

The ratio of the diameter to the circumference is a simple math relationship and Lightburn can send the code to run it at the requested surface speed.

This operation is pretty simple … try not to over complicate the procedure. If it was this complicated, everyone wouldn’t be using them.

Make sense?

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.