Morning All

I’m wondering if anyone can help me as I’m tearing my hair out here …

We have a Chinese yellow & black laser (we call it a 6040) with a roller rotary attachment and a Ruida controller.

We’ve used the rotary previously, fairly successfully but the images were stretching. We had corrected these by eye by squashing the image, but I decided we ought to work out how to do it correctly.

Last night I thought I’d worked out the steps per rotation by testing using a 30mm box. Initially it was very stretched but with trial and error I reduced it to the correct size so I engraved a vase, which came out beautifully. This involved an image that was on just one part of the vase, not the whole circumference.

This morning I thought I’d try something a bit more complex and go for an image that would cover a whole vase.

I’ve created my image to the exact number of pixels, so there’s no stretching involved before I import it in to Lightburn. I’ve then imported it in and tweaked the size, mirroring etc so it SHOULD be exactly the same size as the vase (circumference and height).

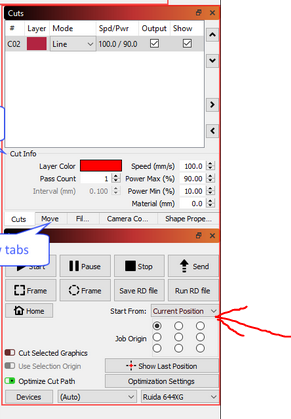

When I turn on the laser, it runs through it’s alignment and the rotary turns, but when I go in to Lightburn to set up the rotary (using EXACTLY the same settings as last night, on exactly the same sized vase) it’s all wrong!

When I framed the image it looked OK so I attempted to engrave the vase and got a frame slop error!

I’ve double checked everything with the image and it should all be fine (nothing outside the area, the size should be perfect) so I went to check the rotary settings…

The enable rotary slider wasn’t green so I corrected it and the rotary just made a nasty whirring sound but the rollers didn’t actually turn.

If I unclick to enable the rotary I can Frame the image, but it seems too big.

I double checked the settings for the rotary and they’ve all messed up, even in the original file that I used last night, so I reset them to exactly the settings that worked last night and tried again.

Again I got the frame slop error so pressed enter anyway and the laser started but the image is stretched!

At this point my vase is ruined anyway so I tried the 3cm box test again, using the exact same settings from last night on the exact same size vase from the file that worked (but removing the image that worked) and it’s way out! 26cm! I double check the settings again and they’ve changed, again!

It’s like it’s not actually storing the rotary set up data I’m entering and, as I say, if I enable the rotary, the rollers just make a horrible sound and won’t turn.

What on earth have I done wrong?!

I’m not terribly technical, I’m the creative half of our business, rather than the practical one (who can’t come and sort it due to continuing coronavirus restrictions in Wales), so would appreciate fully dumbed down responses please!

I’m using Windows 10 and Lightburn 0.9.14 (as I say with a Yellow & Black Chinese 100W laser with a 600 x 400 bed and a roller rotary attachment).

ANY help, gratefully received!

Thanks

Lesley