I have a Longer Ray5 10W laser and just installed a generic laser rotary engraver - on the advice from people in this forum. as well as the LightBurn forum, that you did not need an expensive rotary laser because the rotary laser just works off of the Y-axis connection from the controller. The supplied wire is connected properly. One end to the step motor on the rotary engraver and the other to the Y-axis wire coming from the controller. I went into LightBurn V1.4 and configured the rotary information [roller-style] following YouTube and other information researched. I used a caliper to measure and set the width of the rollers, I checked [selected] the Y-axis box and Enable Rotary box. When I hit the TEST button in that rotary configuration window, the Y step motor simply buzzes. I immediately shut off the machine. Started it up once again, moved the laser head to the middle of the work area, and then went into MOVE function of the Lightburn software and was able to move the laser head to the left and right along the X-axis using the left and right arrows in the MOVE function, but as soon as I hit the up or down button/arrows for the Y-axis, the step motor buzzed just for a second, and every time I hit the up or down arrow - it simply buzzed [no movement] just for a second after each push, only did it two times to not damage the motor. Something’s wrong. Can’t figure it out. Any and all help would be greatly appreciated. The controller is " MKS LTS V1.1" if that helps - and - the latest firmware from Longer was installed with the dlc configuration file when I added the limit switches, which I still can’t get to work properly.

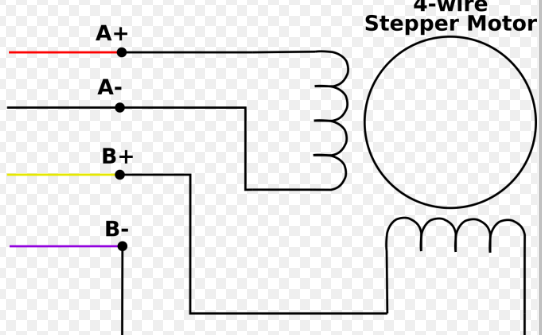

Pretty good chance two of the field wires are reversed on the connector. (Most likely) That’s what they do, just buzz. Doesn’t cause any harm unless you kept at it, then maybe.

To determine the A and B pairs, you can put a simple continuity tester or multi meter on the connector to the motor, the pairs will show continuity amongst themselves, then switch one of them. Either one.

I will check your diagnosis tomorrow. Thanks for a prompt reply. I was told that any rotary engraver can be utilized - it does not have to be the same brand as the laser you use. Correct?

That is correct. Probably an exception to the rule, but I sure don’t know it. Questions though:

Does the rotary have a connector that plugs into where your Y motor plugs in (Or somewhere on the laser)?

When you say wire you mean a 4 wire cable or bundle?

I am understanding a 4 wire motor on your Y and a 4 wire connector on the rotary so no reason shouldn’t work.

(Caveat, I’m a fiber guy, but I do play around with steppers and drivers and controllers as a hobby).

The rotary stepper motor had a 6pin male conector (but only 4 wires on the female connector that goes into it). On the other end of the supplied wire with the rotary, an adapter wire was added - which allows it to connect to the controller’s Y-axis cable (it’s a 6pin connector but only 4 wires). When I disable the rotary in LightBurn, I can cut/engrave like normal.

When you said the wiring needs to possibly be reversed, do you mean reverse both wires - or just one (an A to a B - either A to either B, or vise-versa…or switch both wires (reverse both)?

And when I say all works fine when I disable the rotary, of course the wiring is reconnected back to normal.

Just one or the other. It willrun clockwise or counter clockwise depending on your decision

So swap, say, the A+ with the B+ OR A- minus with the B-…. So there is a “+” and a “-“ on each side?

Yes, just went down to the bench. Switching a-’ and a+ reverses direction. Same w b.

Switching one a with b vibrates. My drivers need a power cycle if I just unplug and sw wires or nothing happens.

With multi meter get 24vDC a+ to a-, same w/b on the driver. Nothing with AC which is strange.

Al, it’s possible I may have screwed up the wires when I switched him. Do you know anywhere I can purchase a rotary laser cable?

Post a photo of the end/ends. Probably just solder your own up. Laser works with Y axis, you are just talking about the rotary, or did the Y stop also?

It’s time for several photos of the rotary, wires, connectors, etc.

It’s a common problem with the stuttering stepper. As you already discussed, this can be solved by changing the wires. I would start swapping the two middle ones. You just need a needle to get them out of the plug. I wrote some hints for different models here, maybe this is helpful here as well: Rotary roller - Diode Laser Wiki

@misken

Excellent write up. Excellent photos.

One thing to point out, It is hard on driver boards to disconnect the stepper motor while under power. Even when not turning. While obvious when disconnecting and swapping wires, the XY switch would leave open the opportunity to switch while hot.

Al, when removing the ends of the wire from the plastic connector, two fell apart and are irreparable So, I’m looking into buying a replacement cable. I’m also looking at the Ortur rotary laser - due to a high adjustment benefit on one end of a rotary laser for wine-type or other “sloped” items. I’ve been told that any rotary laser will work, because they all work off of the Y-axis. Correct? If I can salvage this rotary laser with a new cable, that would be great. So any advice or referrals to a site or company that can provide a rotary cable would be greatly appreciated. Jim

Yes, correct. Though you might need to change the wire order in the plug, as experienced now. But technically, all rotaries work with all lasers.

Just cut off the very end and mount a new connector. Those are usually JST-XH 2.54 connectors, 4-pin. Quite easy to assemble, if you buy a package with plugs and the crimp tool. Or check if there is a local makerspace, experienced people can do that in a minute.

Thank you. Do no a place where I can buy these connectors, package of plugs and a crimp tool?

Something like this: https://www.aliexpress.com/item/4001145869380.html You can also get this at Amazon or eBay, depending on your location, those might be easier.

Thank you.