When working with the rotary there is one acceleration rate for the rotary axis and two speeds related to the rotary axis. The traverse speed and the engrave speed. Working with the speed in the Move window is like a different engrave speed, up to a point.

Please post the value for $111, the engrave speed and the speed in the move window.

An aluminum can is really light and can be somewhat slick. Excessive acceleration combined with high speed motion allows the can to slip for more time on the rollers and move less than it was told to. The aluminum can doesn’t have the benefit of the toothed belt to force it into a precise location.

The engrave speed, usually slower, will spend less time accelerating and will slip less.

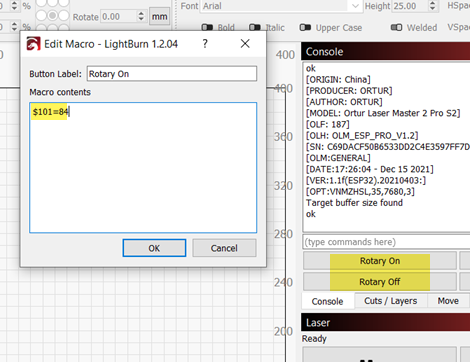

When the Rotary mode is enabled it recalculates the needed steps per mm based on the info available to LightBurn in this window. Turning the rotary tool off turns the steps per mm back to the $101 settings. With the rotary mode off, please return the $101 setting to what it was.

First thing I would offer for troubleshooting is to set the Y axis acceleration to half its current value. What is the current value for $121?

The settings report available through the console window by entering $$ may be of benefit here. Please copy and paste the report into a reply here.

I’m not as familiar with the version you’re using. I can download it for testing and my engraver / rotary may be similar enough that some of the settings will apply.

Let’s start with speeds and accelerations first.