In the rotary setup there is an option to choose between a Chuck and Roller style rotary. Is there an actual difference in how the software talks to the controller depending on whether it is a rotary or chuck? Looking at it mechanically I don’t see why it would matter.

Hi Terry, welcome to the best laser site for using your laser.

If you mean actually communications, no, but the actual values sent may be different.

A rotary is simply a way to use the Y table axes to drive a circular object, to the controller, it still looks like the Y axes and the same rules apply.

Speed on a cnc machine is actually referred to technically as surface speed… this relates to how fast the material moves relative to the tool bit (or laser). Both the table and the tool can be moving, so surface speed is really the proper term.

A wheel or roller rotary is setup so that when you put an object on it, the wheel or roller drives the surface of the object, so no matter the size of the object you have the same surface speed.

With a chuck, it’s being rotated around it’s center axes.

A pencil at 1 rpm has a surface speed that is slower than a larger item, like a 55 gallon drum. So the software has to know the diameter of the object to compute a proper surface speed.

If you take one rotation of a pencil to one rotation of a drum, the surface speed of the drum has to going much faster, surface wise due to a larger distance or circumference.

It’s simply the diameter of the object determine the circumference and the circumference is relative to the surface speed. Longer distance to get around the object the faster the surface must move in during the rotation.

How much of these computation are dealt within the controller and how much with Lightburn, I don’t know.

Once a roller is setup, you don’t need to know the objects diameter, with a chuck it has to know the diameter.

Makes sense?

Sing out if you don’t follow…

![]()

Great explanation. That does answer my question and answers another that I didn’t ask.

I don’t have a chuck rotary. I have a wheeled rotary which I guess mechanically functions the same as a roller.

I have two lasers. One uses Lightburn and the other K40Whisper. In K40 whisper I have to play with the Rotary Scale Factor every time the objects size changed. In Lightburn I didn’t have to do that necessarily and I was confused as why changing the diameter didn’t affect the image on the object. So its all about getting the steps right and the diameter of the wheel.

Again Thanks,

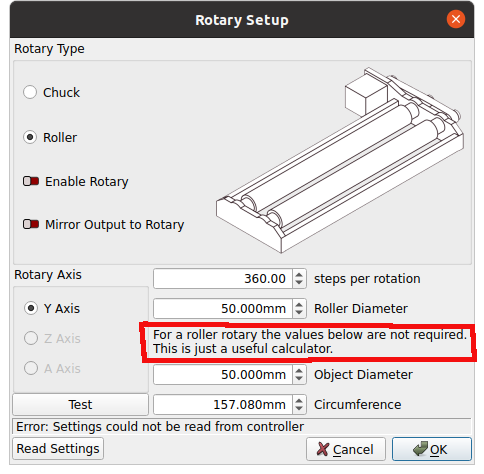

Great, the idea is to get across to you what’s going on. Notice this in the GUI?

It’s great for determining the size for a tool layer with the size based on the circumference when building the artwork. You can see the size of the circumference and ensure your work fits on the object.

Have fun

![]()

Actually, I never noticed that until today. After reading your explanation, I opened that menu and read that for the first time. As they say reading is fundamental.

Thanks,

It’s just the tree in the forest game.

Lightburn has some very good videos… they just released one that’s on selection or how to… You should watch it… very helpful…

Good luck

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.