Rotary setup is really pretty straight forward…

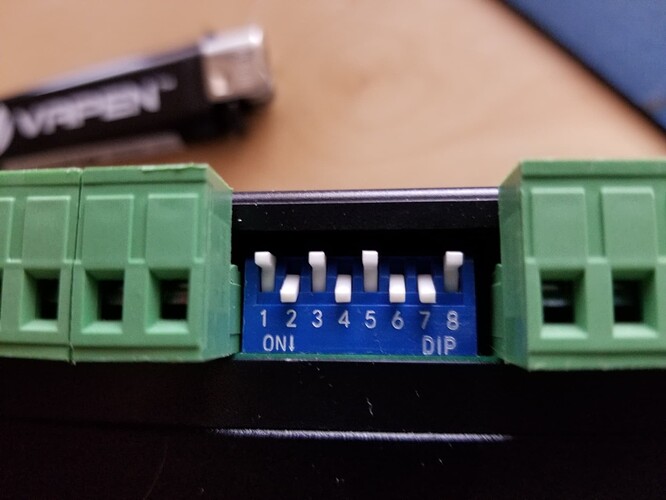

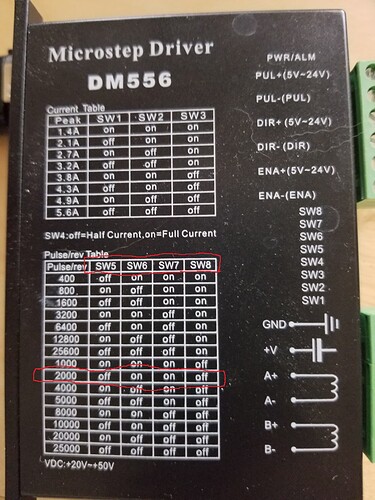

Whatever axes you’re using, read the motor drivers steps/rotation off the switches…

Match them up with the placard…

My setting is 2000 steps/rotation.

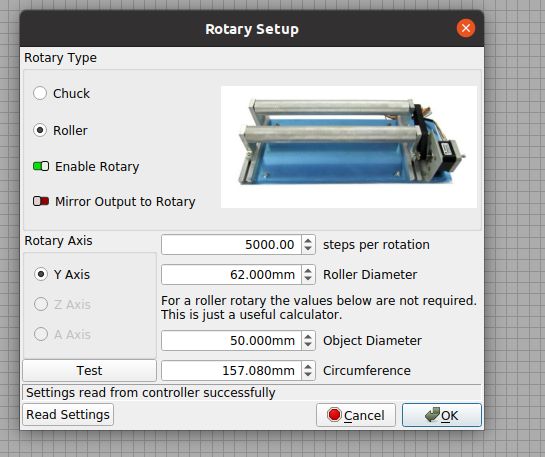

With a chuck type, you would use this value in the rotary gui.

If it’s a wheel type rotary, you need to apply a ‘ratio’ of the motor to the driving wheel.

Mine is 2.5 the motor will turn 2.5 times for the ‘wheel’ to turn one rotation.

Steps/rotation is 2.5 * 2000 = 5000 in the gui…

You will have to enter the wheel diameter, 62mm in my case.

For the chuck type, you will have to enter the diameter of each object…

![]()