Verily it is written: Hell hath no fury like that of an unjustified assumption.

And, wow, I am so good at those … ![]()

My KT332N manual claims it has a dedicated rotary function:

U axis function configuration :The U axis can be configured as a platform, a feed axis, or a rotation axis.

However, that option appears nowhere in the console Menu choices nor the LightBurn Machine Settings list, so it’s probably buried even deeper in the firmware, where only the vendor’s setup program can go.

On my machine, the U axis drives the platform motor, which is what I’d call the Z axis; there are only U axis terminals on the back of the case. Given the lack of the config option, there are no other choices.

Based on that manual hint, however, I’d assume the controller could use the Rotary info to control the rotary motor according to the U axis acceleration / speed values (at least). Whether it would also pay attention to the limits & suchlike is an open question.

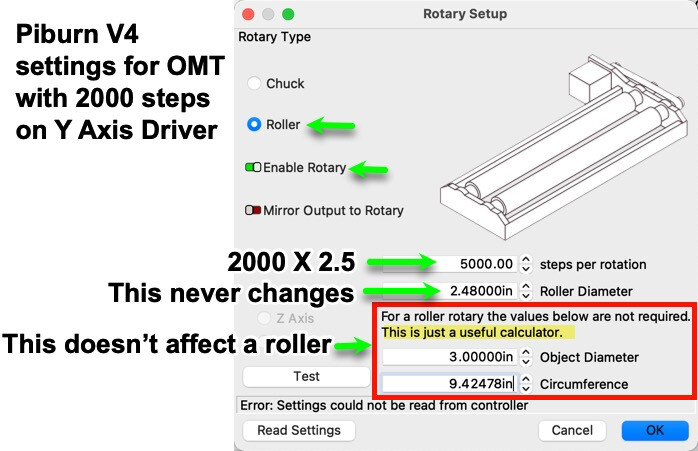

Which may explain why the LightBurn GUI goes through such contortions: there’s no way to tell exactly what the Enable Rotary function will do.

On my machine, with a rotary plugged into the Y axis and the U axis not available for rotary operation, the controller’s Rotary values likely have no effect. On somebody else’s machine, with a different deep vendor config, the U axis would spin the rotary motor like crazy.

However, LightBurn has options to select only the Y / Z / A axis for rotary control, with all but the Y option unselectable here, so I assume the Y axis hack is the “standard” way of making a rotary move and nobody uses the U axis.

LightBurn probably sets the Rotary parameters in the Ruida config, in the hope they might do something. In my machine, they do absolutely nothing, but ya never know.

In my defense, you were getting kinda salty about your background and methodical approach, so I pretty much assumed you’d RTFM and didn’t need handholding after I aimed you at that section:

We would like to specifically call out the

Vendor Settingssection that will appear for Ruida controllers. These settings are typically set at the factory where your laser was manufacturered or configured and it’s best not to touch any of these unless you really know what you are doing.

Nah, I’d never overlook anything that obvious, either.

![]()