I ran across a thread were someone wired a switch in to use the rotary. I’d like to do the same, I swapped the plugs out so much I’m afraid the pins inside the plugs will wear out. I’m not a electrician by any means, I’d like to find someone who might be able to dumb it down (way down) for me so I might be able to install said switch.

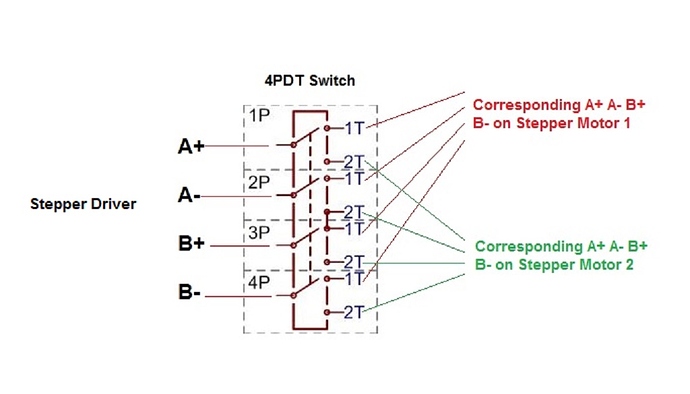

You could use something like https://www.amazon.com/Uxcell-380VAC-250VAC-Position-Toggle/dp/B01C8CSW5W if you didn’t want to worry about soldering.

Lop off the connector of the existing Y-Axis. Wire it to the center set of screw terminals. Color match and wire the lopped off cable to one of the outside set of connectors. Lop off the rotary connector and wire it to the other outside set of connectors. Make sure you have enough wire length free to connect everything.

Plug back in to the receptacle. Flip the switch for whichever way you wanted to run (make sure you power-off, first).

You could get more complicated, starting with using connectors for everything and soldering, doing some extra electronics and wire in a relay, etc.

For simple, though. Turn off the power. Hack off the connector. Wire everything to the switch. Find a place to put the switch and drill a hole for it.

Get fancy and add https://www.amazon.com/Antrader-Plastic-Toggle-Dustproof-Waterproof/dp/B07L2S38JT with a “TURN OFF POWER” label if you want.  This one has a spring in it that might get in the way, but that’s the idea. Make sure the switch mounting diameter and the cover hole diameter match.

This one has a spring in it that might get in the way, but that’s the idea. Make sure the switch mounting diameter and the cover hole diameter match.

Wwhere do you put the rotary when not in use?

My plan is to still use the little side port inside my laser. I’d just unplug it from there and take it out.

If you use crimp on fork or circle connectors, ensure they are solidly crimped. When I added my switch, one of the twelve connections was intermittent, even without movement. I figured the smart way to fix it was to tug on every one of them. Found it, re-crimped it and it’s great.

For mounting, I screwed a piece of aluminum angle to a convenient location in the controller bay and routed the wiring easily to that spot. As Rick suggests, adding a label “Power off before switching” is a good idea. It’s become second nature now, but you don’t want to cook a component by forgetting.

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.