I have a rotary attachment on my Boss Laser LS-1630 using a chuck attachment. I’ve been doing test burns of a circle to make sure it’s not an oval. I’m engraving on a tumbler 3.50 inches in diameter at 10,000 steps per rotation. The attached photo shows my issue. One side of circle is round but the opposite side is not round. It has a flat side. Anyone else have this problem before?

Does it work with the ‘test’ button at ‘Tools → Rotary Setup’?

You should get one rotation forward and then one rotation back?

Set up for the diameter of the chuck?

If this is working and your setup is ok, then the only thing this reminds me of is some kind of slippage.

You steps/rotation might give you ovals instead of circles if not correct. Where did you get that value?

Mine is a wheel rotary.

Good luck

![]()

I got the steps per rotation value from the Boss instructions for my model. Then adjustsed them until I no longer had an oval. I have a circle now but just on one side. The other side is flat like the 2nd picture. Changing the steps per rotation worked before and had no issues.

With a chuck type rotary you should not be changing the steps/rotation. Actually I don’ think either type setup properly would need that.

What compensates for the different circumference is the ‘diameter’ value you set. This isn’t required with a roller type rotary.

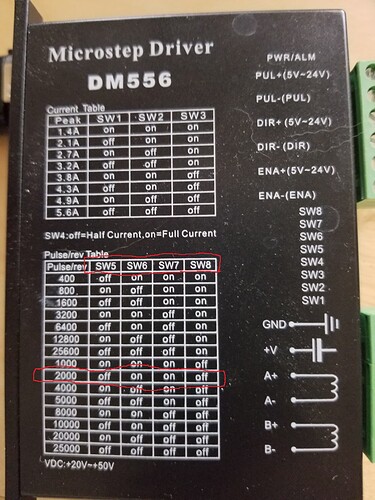

It’s probably right, I’ve heard that value before. On my PiBurn, I had to check the Y axes motor driver to read the steps off it and use that value.

The rotary looks like it’s not moving on the second half or flat side.

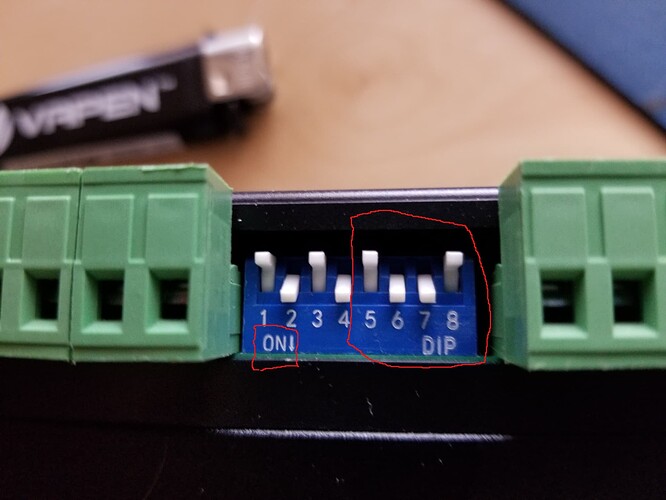

Can you double check the motor driver and see if it’s set for 10,000 steps/rotation?

Mine is set for 2,000 steps/revolution.

That’s interesting. It’s like it rotates so far then stops. Assuming it’s trying to cut a perfect circle. Just wondering if the optics on the machine are aligned? What happens with other shapes?

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.