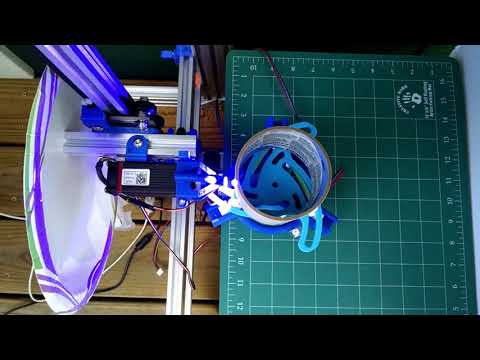

I have a little different DIY laser engraver that works horizontally or vertically. In order to use a rotary axis, I designed a self centering turntable to hold the object centered & place the engraver in vertical position using the cantilever arm as the X-axis. That is usually my Y-axis, but lightburn does not seem to have an option for changing the linear movement axis.

Anyway, my problem with the rotary axis seems to be that it moves faster in the rotary axis than in the X-axis. I have set the rotary axis as the Y, but will probably change that to Z later. You can see this problem in the 1st part of the linked video below when it is drawing a rectangle around the object.

In the rotary section of Lightburn, I have 32 mm per rotation (DRV8825 drivers) and Chuck rotary type set. Any help would be appreciated.

Thank you.

Below are the GRBL settings I am currently using in this configuration.

Grbl 1.1h [‘$’ for help]

$0=10 ;Step pulse time, microseconds

$1=255 ;Step idle delay, milliseconds

$2=0 ;Step pulse invert, mask

$3=3 ;Step direction invert, mask (invert x & y)

$4=0 ;Invert step enable pin, boolean

$5=0 ;Invert limit pins, boolean

$6=0 ;Invert probe pin, boolean

$10=1 ;Status report options, mask

$11=0.010 ;Junction deviation, millimeters

$12=0.002 ;Arc tolerance, millimeters

$13=0 ;Report in inches, boolean

$20=0 ;Soft limits enable, boolean

$21=0 ;Hard limits enable, boolean

$22=0 ;Homing cycle enable, boolean

$23=0 ;Homing direction invert, mask

$24=25.000 ;Homing locate feed rate, mm/min

$25=500.000 ;Homing search seek rate, mm/min

$26=250 ;Homing switch debounce delay, milliseconds

$27=1.000 ;Homing switch pull-off distance, millimeters

$30=1000 ;Maximum spindle speed, RPM

$31=0 ;Minimum spindle speed, RPM

$32=1 ;Laser-mode enable, boolean

$100=160.000 ;X-axis steps per millimeter

$101=200.000 ;Y-axis steps per millimeter (200 * 32 = 6,400 rotates 1 revolution with 1.8 nema17)

$102=200.000 ;Z-axis steps per millimeter

$110=500.000 ;X-axis maximum rate, mm/min

$111=500.000 ;Y-axis maximum rate, mm/min

$112=500.000 ;Z-axis maximum rate, mm/min

$120=100.000 ;X-axis acceleration, mm/sec^2

$121=100.000 ;Y-axis acceleration, mm/sec^2

$122=10.000 ;Z-axis acceleration, mm/sec^2

$130=435.000 ;X-axis maximum travel, millimeters

$131=435.000 ;Y-axis maximum travel, millimeters

$132=0.000 ;Z-axis maximum travel, millimeters