When I try to test out my steps per rotation using a rectangle the rotary will start turning clockwise on the long side of the rectangle then engrave a line for the end of the rectangle, but when it should rotate counterclockwise to finish the rectangle it actually continues clockwise the same distance as the counterclockwise last side of the rectangle should have went. This only happens when Line is selected, not if fill is selected. (Newb also, which doesn’t help). Thanks in advance.

I don’t have a roto boss, mine is a piburn, but the setup should be the same…

How did you setup the steps/rotation and what is the ratio for your machines driving wheel?

![]()

For a 22 ounce Polar Camel Tumbler, we were dialing in near 3,600 and the Roller diameter I have in is 1.9685 inches (measured by caliper) and the diameter of the tumbler is 3.1185 (measured by caliper).

It’s digital until it gets to the roller…

What I meant was

- where did you get the steps/rotation?

- what is the ratio to the rollers?

![]()

We were working on calculating the Steps/Rotation, dialing it in using ComputerCreationz you tube video. How would one figure out the ratio to the rollers?

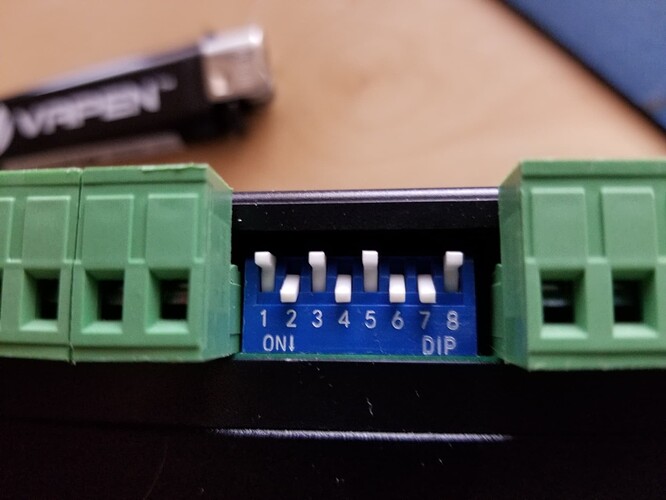

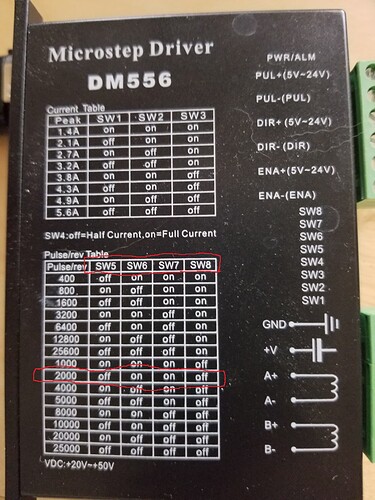

Find the proper motor driver… read the switch settings.

Notice the ‘on’ direction… 5 - 8 of mine read off on on off

2000 steps/rotation for the motor…

The Boss manual should tell you what the ratio between one motor rotation and one wheel rotation…

Mine is 2.5

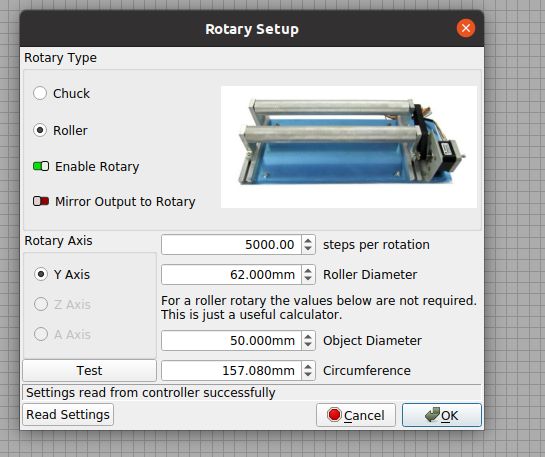

The steps/rotation in my case is 2000 x 2.5 = 5000 steps/rotation in the gui…

My wheel is suposedly 63mm, but it’s close to 62mm … this is where you do the fine adjustment… not with steps/rotation, that’s digital…

Make sense?

![]()

Ok, that definitely helps. I found my switches and those led me to 4000 steps per rotation for the motor and the ratio I found in a Boss Spreadsheet on Thunder’s site which is 1.167777 so 4000x1.167777=4666.668 correct?

Edit*** so in the GUI I enter in the 4000?

is the value (I think it will take a decimal/fraction value, worst case use 4667) for the gui… then you apply the wheel diameter…

The steps/rotation you mentioned as being 4000 is what’s required to rotate the motor one complete turn and back… you have to apply the ratio as you want the ‘roller’ to rotate one turn and back…

With a ‘wheel’ (roller) driven rotary the diameter of the mug is not required for basic operation. The ‘driving’ wheel diameter is used to move the object just like the Y axes moves.

Diameter might be nice to know when you’re doing the artwork… so you know the area you have to work with…

With a ‘chuck’ type, you set up the motor to turn 1 rotation. Then the software has to compute the ‘surface’ speed of the mug, which requires it’s diameter…

I do everything in mm, mainly it’s easier on my brain than the imperial ‘length’ of the ‘kings’ foot, then lets divide it by some easily computed value to make it easier, like 12 ???

Lightburn keeps all of it’s number internally as mm … converts them for display… I believe …

Clarified?

![]()

Yes, that makes sense now. I am learning pretty quick that I need to retrain my brain to think of these measurements in the metric system. Now that I understand the Steps/Rotation a tad better. Any ideas as to why the rotary won’t turn counterclockwise when framing/burning the rectangle?

Since it’s never run before, I not sure where to look…

Is this working on a Boss machine and you purchased it from Boss?

I’d think they’d have some kind of support for this…

My only thought is that it’s not wired properly… but don’t know…

![]()

Will do, thanks for all of the help!

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.