How can I stop soot from accumulating on the laser head tip when lasering LASERMAX rowmark? I have to stop & clean off the tip sometimes after a run that only takes a few minutes. This is really slowing down our production time.

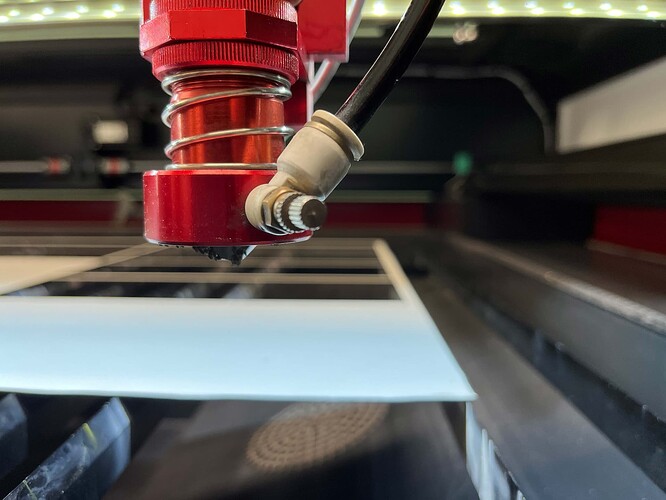

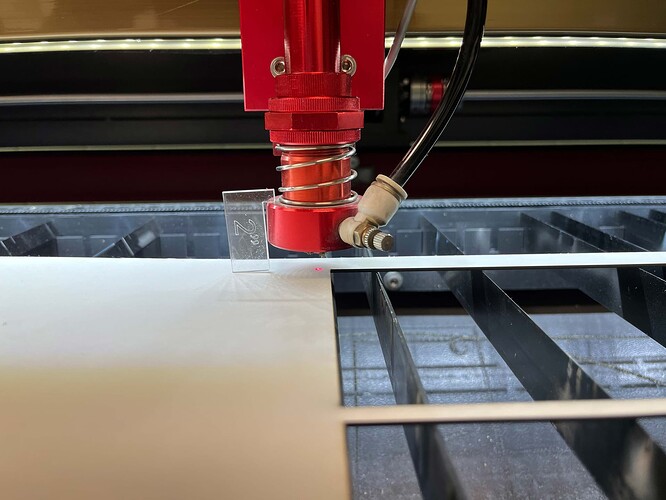

Could you maybe post a picture - next oportunity of:

a) how you focus vs material

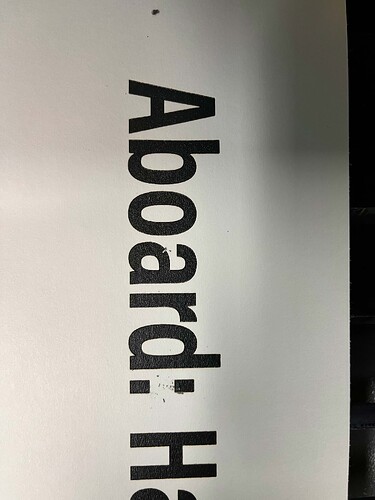

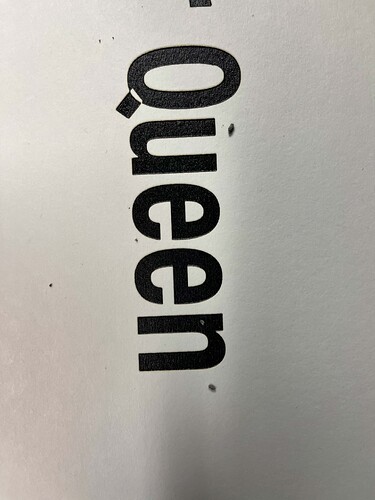

b) how it looks when you think you need to clean it

c) your air assist setup

Thanks for responding. Yeah, I guess I may have been a little vague. I started a new job so I should have good pics when done.

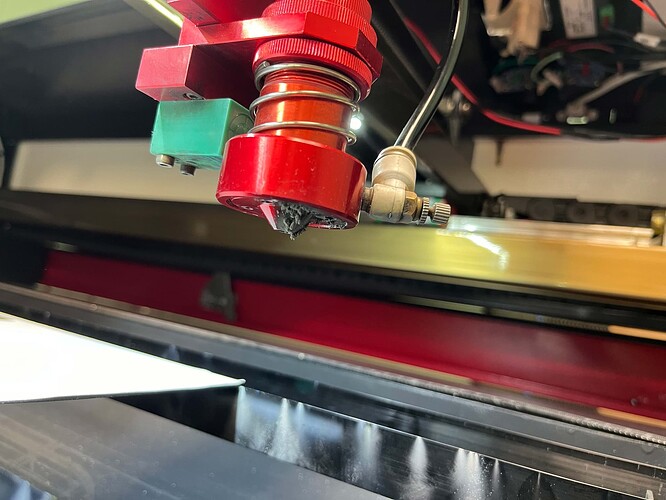

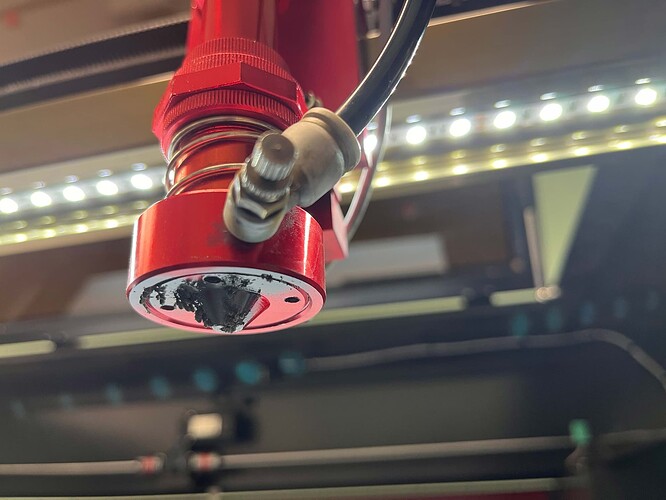

Attached are pics of a job that was just run.

Machine: Boss Laser LS3655 150 watt CO2 laser w/auto focus

Material: 1/16" LASERMAX rowmark

Lightburn: 420/16 @ .05 line interval

Total laser time of job in pics: 18 mins

Does look a little nasty!

I would suggest - but just thinking out loud - you might need a split air assist just to blow the debree away from getting stuck to the nozzle. Horizontal airflow in this case

Shouldnt be a difficult endeavor modification, but given the distance to the material I would suppose is the only practical approach to avoid your workflow to be interrupted every batch

Some materials end up stuck the nozzle… I don’t know what you can do about it except change the speed/power settings to find a combination that will allow less soot to end up on the nozzle.

I think inherently, this is what occurs when debris is vaporized… it seems to stick to the material that is near and has a lower temperature where it can condenses.

I have that issue with reflective glass mirror backs… After a job, I clean the nozzle tip up.

![]()

Hi - I used to use a Beam Buddy (sic) compound lens that ran only 3mm above work surface - found that the results were not worth the extra time/effort / over my 1.5 or 2" lenses - But the build up on the lens casing was heavy. found that the quickest and easiest cure was just to give the bottom of the lens holder a quick swipe with a soft old toothbrush after running a job - End Of Problems for me anyway! Just FWIW. Cheers

Pretty much the same as my short lens…

Have fun

![]()

Maybe a bit outside the box, but i’ve seen stationary brushes installed on industrial CNC equipment to clear debris from tools. Mount the brush at the furthest corner and set that as your finish position so it automatically wipes the nozzle after every job.

I like this idea, almost like… the “srubber” on multicolor 3d printers