I have a Ruida 644XS which has been working very well until recently when it just stopped burning.

I found out the tip of the glass laser tube had broken off. After glueing it back it worked for a while but detached again so I decided to buy a new tube.

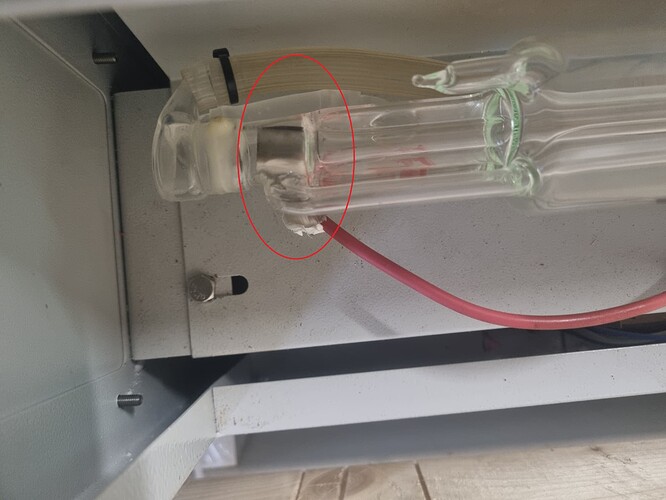

I installed the tube about 10 cm from the mirrors, connected the wires, let the water fill up the tube and fired up the power. The red guiding light is showing but when trying to laser /pulse there’s nothing happening. I thought this might have something to do with needing to recalibrate so I put some tape on the mirror to see where the beam was firing but again when trying to pulse or even start burning a project nothing happens to the tape.I have taken some pictures, it also looks like something on the left is not correctly placed in the tube, any idea what I can try to make it working?

Assume you connected the anode (hot end) without an issue?

Do you have a mA meter … did it draw any current?

The collar you have circled looks like it’s the anode plate used to excite the tube… I have never seen one ‘tilted’ like that. Don’t know if that’s an issue or not… Hopefully the tube was tested… I don’t think they can move after the tube is closed up … again don’t know…

Where did you get the tube and why do you have it 10 cm from m1?

![]()

Yes, it should be correctly applied, the wire is definately making contact and the pin on the tube definately didn’t move while connecting the wire.

I do have an mA meter but as I’ve only been using it as is until now I have no idea how and where to measure.

It DOES have a test sticker on it but I’ll also answer your last question first, I had a friend order it and he got it off one of those cheap Chinese sites so that may as well be the problem. The first one which arrived was literally just a box of broken glass. This one did look intact from the outside.

The reason I have it 10 cm off m1 is because of some videos I watched on how to replace the tube.

I’m thinking more along the lines of an installed mA meter in the cathode of the tube… That would tell you if it’s conducting or not.

Do you have the chiller running to see if the coolant is flowing correctly?

In the first shot of the anode end of the tube there is discoloration on the opposite side of the tube… Is this there or just from light reflecting off the red anode wire?

My tube has a visible pink ‘gas’ when it’s not firing and it’s brighter when it is firing… I don’t think I see that in your tube.

There really no convenient way to test an lps without something to load, such as a tube.

Just from the fact it was working and a tube replacement from a more than likely 2nd vendor tube…

I’ve seen people buy RECI tubes rated at 50W when they get them the test states 45W… These are 2nd vendor that didn’t work well enough to be a real 50W tube, so RECI sold them off to other vendors…

There is a mirror at each end of the tube to bounce the light back and forth. The output has a small hole for some of the energy to escape… This is the light amplification part of a laser. The mirror alignment is critical and difficult to do. Some of them are not proper and don’t produce full wattage end up as seconds … eventually being sold by these low cost tube sellers.

Russ Sadler recommends Cloudray for selling proper tubes… I hear good/bad about them, but they seem to eventually make people happy.

I’d suspect the tube at this point and do a good coolant flow to ensure no breakage and see if you can actually see the gas mixture in the tubes smallest center tube.

Good luck

![]()

Sorry for the late answer.

There indeed is a little bit of red something on the tube.

I did not see any “pink gas” or anything similar. In the meanwhile I have ordered a new tube through cloudray but may have found the problem. After I attached everything (the tubes from cloudray are much better prepared for connecting) I found out that the water is filling the tube but after that has trouble coming out again. I suspect there’s something with the flow sensor as all the water hoses are kink free and when I look at the water flow that’s coming directly out of the pump its fine too so I ordered a new sensor and am waiting for it to arrive and test further.

Thanks for the help so far!

In an emergency you can bypass the sensor with tubing and turn that error checking off in the Ruida…

If you do this, error checking for coolant flow is now on you as the machines sensor is disabled…

Take the ‘downstream’ side of the sensor tube off and see if coolant flows out… if it doesn’t, replace that and repeat with the ‘upstream’ side… easy check

Or just see if you can easily blow through it.

![]()

This topic was automatically closed 30 days after the last reply. New replies are no longer allowed.